An n-channel MOSFET and comparator protect a lithium-ion (Li+) charger and system from reversed-polarity battery connections. The circuit is shown for a one-cell charger, but can be expanded for more cells without adding parts.

A similar article appeared in the March 2007 edition of Power Electronics Technology.

Many battery-powered applications use diodes for reverse-battery protection. However, a diode does not always protect a battery charger when the battery is inserted incorrectly. When the battery is inserted backwards, this can sometimes cause a large amount of current flow through the charging circuitry, potentially destroying both the battery and the charger. Of course, the best way to prevent reverse-battery insertion is to make it mechanically impossible for the user to insert the battery incorrectly. Many companies do this by designing unique physical battery and charger configurations.

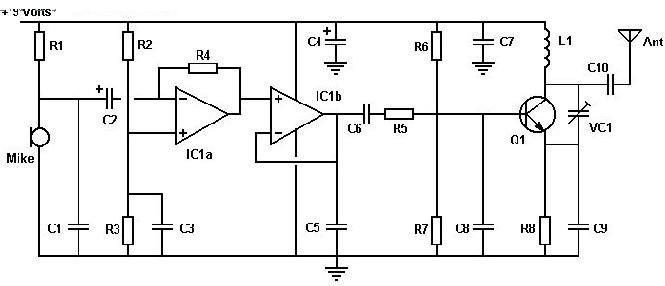

There are many battery shapes that, unfortunately, allow users to incorrectly insert the battery. The simple circuit in Figure 1 gives a single-cell Li-ion battery charger added protection from damage due to backward battery insertion. In the circuit, the MAX1551 linear-mode single-cell Li-ion battery charger delivers the charging current to the cell from either an AC adapter or USB power supply. The MAX9001 is also powered from one of these supplies.

Figure 1. This circuit protects the MAX1551 single-cell Li-ion battery charger from surge current caused by backward battery insertion.

During normal operation, the MAX9001's comparator output is high and the FET is on. When the battery is inserted backwards, the MAX9001's output goes low, a condition that turns the FET off. This blocks the flow of potential battery surge current out of the BAT terminal. The rapid switching of the FET keeps the current surge to less than 50mA; that surge lasts for less than 200ns before dampening, as shown in Figure 2. Connecting the battery in reverse without this external protection would destroy the MAX1551.

Figure 2. The top curve of this oscilloscope capture represents the backward insertion of the battery in the Figure 1 circuit. The bottom curve is the battery current.

When the cell is inserted backwards, the potential at the inverting terminal of the MAX9001 increases beyond the supply voltage. Resistor R1 limits the amount of overvoltage current sourced through the on-chip electrostatic discharge (ESD) diode. Larger resistor values can be selected to limit the reverse-battery leakage current through the comparator diodes, but the trade-off is slower operation and larger transients. In the test circuit used, VCC = +5 V and R1 = R2 = 50kΩ. The low-side FET enables this type of circuit to work for multicell batteries, as long as the comparator inputs are within the absolute ratings of the comparator. Using the FET rather than a discrete silicon diode also enables the battery to remain connected to the load, allowing for seamless charging and discharging that is transparent to the application.

A similar article appeared in the March 2007 edition of Power Electronics Technology.

Many battery-powered applications use diodes for reverse-battery protection. However, a diode does not always protect a battery charger when the battery is inserted incorrectly. When the battery is inserted backwards, this can sometimes cause a large amount of current flow through the charging circuitry, potentially destroying both the battery and the charger. Of course, the best way to prevent reverse-battery insertion is to make it mechanically impossible for the user to insert the battery incorrectly. Many companies do this by designing unique physical battery and charger configurations.

There are many battery shapes that, unfortunately, allow users to incorrectly insert the battery. The simple circuit in Figure 1 gives a single-cell Li-ion battery charger added protection from damage due to backward battery insertion. In the circuit, the MAX1551 linear-mode single-cell Li-ion battery charger delivers the charging current to the cell from either an AC adapter or USB power supply. The MAX9001 is also powered from one of these supplies.

Figure 1. This circuit protects the MAX1551 single-cell Li-ion battery charger from surge current caused by backward battery insertion.

During normal operation, the MAX9001's comparator output is high and the FET is on. When the battery is inserted backwards, the MAX9001's output goes low, a condition that turns the FET off. This blocks the flow of potential battery surge current out of the BAT terminal. The rapid switching of the FET keeps the current surge to less than 50mA; that surge lasts for less than 200ns before dampening, as shown in Figure 2. Connecting the battery in reverse without this external protection would destroy the MAX1551.

Figure 2. The top curve of this oscilloscope capture represents the backward insertion of the battery in the Figure 1 circuit. The bottom curve is the battery current.

When the cell is inserted backwards, the potential at the inverting terminal of the MAX9001 increases beyond the supply voltage. Resistor R1 limits the amount of overvoltage current sourced through the on-chip electrostatic discharge (ESD) diode. Larger resistor values can be selected to limit the reverse-battery leakage current through the comparator diodes, but the trade-off is slower operation and larger transients. In the test circuit used, VCC = +5 V and R1 = R2 = 50kΩ. The low-side FET enables this type of circuit to work for multicell batteries, as long as the comparator inputs are within the absolute ratings of the comparator. Using the FET rather than a discrete silicon diode also enables the battery to remain connected to the load, allowing for seamless charging and discharging that is transparent to the application.

电子发烧友App

电子发烧友App

评论