步骤1:附件

所需的附件是:

框架

Arduino UNO R3主板

扩展板

电机驱动模块

PS2无线控制器SONY(模型遥控器或枪支遥控器)

锂聚合物电池(Li-Po 2S)

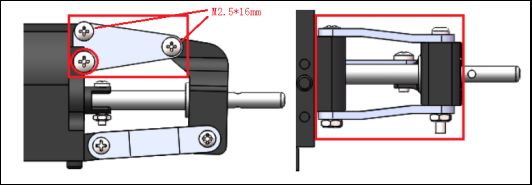

步骤2:转向杯和变速箱轴

每个附件是2套,可以组装2套,然后在底盘上安装。

黑色转向杯x 2

旋转轴x 2

轴承x 4(内侧4外侧8mm,内侧8外侧12mm)

销x 2

六角形x 2

车轮x 2

M4防松螺母x 2

65mm车轮x 2

步骤3:安装伺服配件

将L形支架固定在伺服系统上,注意到括号的长度(红色圆圈)。在转向器上安装转向角之前,请先将其对准90°(1500μs),以方便后续安装和调试。

M2.5 x 10mm螺钉x 1

M3 x 6mm螺丝x 1

M3 x 8mm螺丝x 4

M2.5防松螺母x 1

M3螺母x 4

MG996R伺服x 1

球头操纵杆(短)x 1

舵角x 1

L型支架x 1

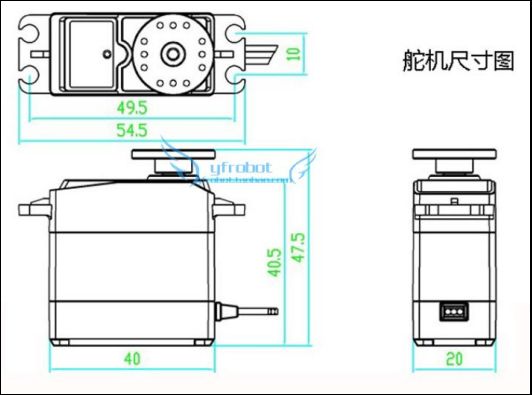

名称:MG996R

电压:4.8-7.2V

电流:400-800MA

转向器扭矩:10kg.cm

极端角度:180°

电线长度:30CM

齿轮材料:金属

控制系统:更改脉冲宽度

伺服接线:数字端口I/O4

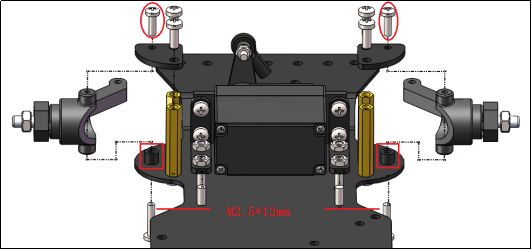

步骤4:连接2个侧面转向杯

长连杆在上孔中,连接两个侧转向杯;短连杆位于下孔中,方向盘连接在一侧,舵角连接在另一侧,长连杆和短连杆不在同一孔位置。

长连杆孔间距65mm,短连杆孔间距46mm,如有偏差,可进行微调。

M2.5 x 10mm螺钉x 3

长短连杆x 2

步骤5:扁平前部

之前安装时,请确保底盘正反,向上弯曲并将先前装备的转向器和转向杯固定到底盘上。转向盘通过铜柱支撑固定在两侧,塑料缸放置在转向盘下方(前后高度一致),不能拧紧转向盘固定螺钉,以确保转向灵活。

机箱x 1

M3 x 26毫米铜柱x 4

M2.5 x 8毫米螺钉x 2(向上)

M2.5 x 12mm螺丝x 2(向下)

M3 x 8mm螺丝x 12

M3螺母x 4

黑色圆柱x 2(红色框)

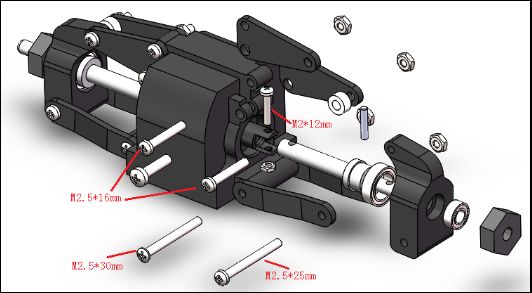

步骤6:后轮差速器部分

最后需要固定后轮座。首先将驱动轴固定在输出轴上。后轮的安装方式与前轮类似;后轮座椅安装在左右两侧, *顶部R安装在左侧,标准L安装在右侧。

下支架是Z形结构。安装时要注意方向,靠近差速器箱宽度,并且轮距很窄。如果不清楚,则可以与图中的视角保持一致。上支架固定需要卸下螺钉才能安装。

差x 1

传动轴x 2

三角支架x 4

Z型支架x 4

后轮座x 2

轴承x 4

六角适配器x 2

销钉x 2

铝制圆柱体x 2(固定在上支架(三角形)和后轮座之间)

65mm车轮x 2

M2 x 12mm螺丝x 2

M2防松螺母x 2

M2.5 x 16mm螺丝x 4

M2.5 x 25mm螺丝x 2

M2.5 x 30mm螺丝x 2

M2.5防松螺母x 8

M4 Locknut x 2

步骤7:将差速器箱固定到机箱上

将铜齿轮安装到输入轴上减速齿轮箱,将锁紧螺钉固定在D型平面上,用L型扳手将其紧固,然后将差速器箱固定在底盘上

M2.5 x 8mm螺钉x 4

齿轮圈0.5模数54齿x 1

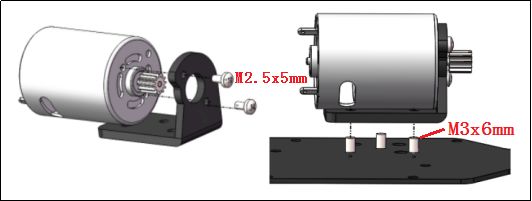

步骤8:电机固定

首先将电动机固定到大支架,然后再固定到机架。支架用M3螺钉固定。电动机固定在支架上,可以调节电动机的左右位置以设置齿轮的紧度。

M2.5 x 5mm螺钉x 2(平头螺钉)

M3 x 6mm螺钉x 3(带垫圈)

L型电动机支架

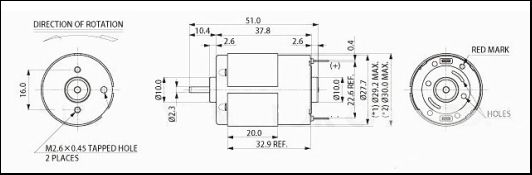

RS380直流电动机

参数:

工作电压范围:3.0-9.0V

额定电压:7.2V

空载速度:16200rpm

空载电流:0.50A

额定速度:14000rpm

最大电流:3.29A

额定扭矩:110g.cm

额定功率:15.8W

启动扭矩:840g.cm

电极的红点为正。

步骤9:上部机箱安装(丙烯酸)

上部机箱由丙烯酸材料制成,并集成了Arduino UNO和Raspberry Pi孔,并安装了Rocker开关在矩形孔中

M3 x 8mm螺钉x 9

M3 x 35mm铜柱x 5

Rocker Switch x 1

丙烯酸x 1

步骤10:防撞棉

红色圆圈是铜柱固定孔,保险杠棉被垫圈压住了

M3 x 8mm螺钉x 8

M3垫片x 4

M3 x 16mm铜柱x 4

防碰撞棉x 1

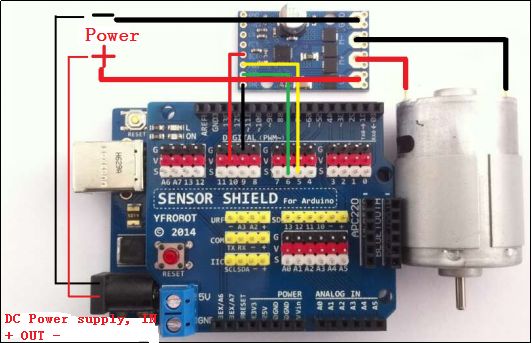

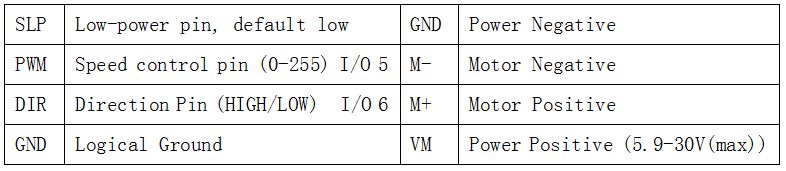

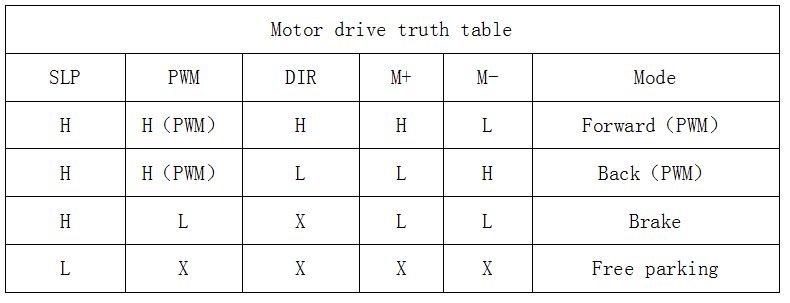

步骤11:电动机驱动模块

MD01电机驱动器由单个H桥驱动器IC和四个外部N沟道MOS晶体管组成。其体积小巧(长*宽:3.3 * 2cm),主板支持5.9V至30V宽电压输入,连续电流可达到17A,支持100%脉宽调制。该模块通过方向DIR引脚和速度控制PWM引脚实现电动机的正向,反向和速度控制。

控制端子支持1.8V-5V逻辑输入,驱动器IC集成了PWM电流调节功能,限制了电机浪涌电流。 SLP引脚的低电平允许MD01驱动器模块进入低功耗模式,从而导致大约9uA的低静态电流消耗。

注:SLP低功耗模式下,默认为低电平,使用时需要保持SLP引脚为高电平,如果不需要使用低功耗模式,则可以直接连接+ 5V。

工作电压:5.9-13V

工作电流:17A

逻辑输入:1.8V,3.3V,5V(max)

PWM频率:100kHz

电流检测:50mV/A(仅在正向或反向时有效)

反射电压保护:无(VM和GND不得反向)

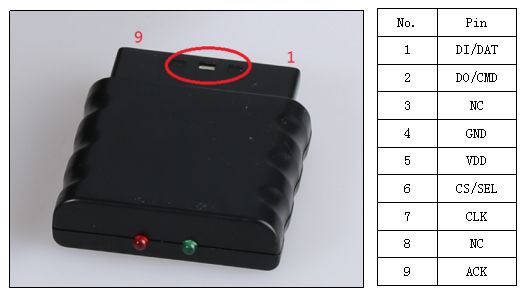

步骤12:遥控器(2.4Ghz)

2.4Ghz遥控器我们使用Sony的PS2也可以使用RC模型控制器;如果您有电子调速器,可能不需要Arduino UNO即可加入,但我们正在学习使用Arduino。

手柄配有适配器板,以方便接线和反向连接保护。该接口从最下面开始: GND VCC DAT CMD CS CLK

/****************************************************************************

* The program controls the forward and backward

* movement of the motor through the Y-axis of the left joystick,

* the X-axis of the right joystick controls the left and right of the servo,

* the button part also writes forward and backward,

* and the right button controls the left and right.

*****************************************************************************/

#include

#include

//for v1.6

PS2X ps2x;

Servo myservo;

#define PS2_DAT A0

#define PS2_CMD A1 //PS2

#define PS2_SEL A2

#define PS2_CLK A3

#define PWM 5 //Motor A‘s pin

#define DIR 6 //Motor A’s pin

#define SERVOPIN 4 //servo‘s pin

#define SERVOMIN 40 //the angle of servo

#define SERVOMID 90

#define SERVOMAX 130

#define TURNLEFT myservo.write(SERVOMIN) //turn left

#define TURNMID myservo.write(SERVOMID) //turn middle

#define TURNRIGHT myservo.write(SERVOMAX) //turn right

#define MOTORFOWARD setMotor(100) //motor forward PWM

#define MOTORBACK setMotor(-100) //motor back PWM

#define MOTORSTOP setMotor(0) //motor stop PWM

bool EnableRockerR = 1;

bool EnableRockerL = 1;

int RMid = 0 ;

int LStop = 0 ;

#define pressures false

#define rumble false

int error = 0;

byte type = 0;

byte vibrate = 0;

void(* resetFunc) (void) = 0;

void setup() {

Serial.begin(57600);

pinMode(PWM, OUTPUT);

pinMode(DIR, OUTPUT);

myservo.attach(SERVOPIN);

SERVOMID;

delay(300);

error = ps2x.config_gamepad(PS2_CLK, PS2_CMD, PS2_SEL, PS2_DAT, pressures, rumble);

if (error == 0) {

Serial.print(“Found Controller, configured successful ”);

Serial.print(“pressures = ”);

if (pressures)

Serial.println(“true ”);

else

Serial.println(“false”);

Serial.print(“rumble = ”);

if (rumble)

Serial.println(“true)”);

else

Serial.println(“false”);

Serial.println(“Try out all the buttons, X will vibrate the controller, faster as you press harder;”);

Serial.println(“holding L1 or R1 will print out the analog stick values.”);

Serial.println(“Note: Go to www.billporter.info for updates and to report bugs.”);

}

else if (error == 1)

Serial.println(“No controller found, check wiring, see readme.txt to enable debug. visit www.billporter.info for troubleshooting tips”);

else if (error == 2)

Serial.println(“Controller found but not accepting commands. see readme.txt to enable debug. Visit www.billporter.info for troubleshooting tips”);

else if (error == 3)

Serial.println(“Controller refusing to enter Pressures mode, may not support it. ”);

type = ps2x.readType();

switch (type) {

case 0:

Serial.print(“Unknown Controller type found ”);

break;

case 1:

Serial.print(“DualShock Controller found ”);

break;

case 2:

Serial.print(“GuitarHero Controller found ”);

break;

case 3:

Serial.print(“Wireless Sony DualShock Controller found ”);

break;

}

}

void loop() {

if (error == 1) //skip loop if no controller found

resetFunc();

ps2x.read_gamepad(false, vibrate); //read controller and set large motor to spin at ’vibrate‘ speed

if (ps2x.Button(PSB_START)) //will be TRUE as long as button is pressed

Serial.println(“Start is being held”);

if (ps2x.Button(PSB_SELECT))

Serial.println(“Select is being held”);

if (ps2x.ButtonPressed(PSB_PAD_UP)) {

Serial.println(“PAD_UP just pressed”);

MOTORFOWARD;

EnableRockerL = 0;

}else if(ps2x.ButtonReleased(PSB_PAD_UP)) {

Serial.println(“ PAD_UP just released”);

MOTORSTOP;

EnableRockerL = 1;

LStop = 0;

}

if (ps2x.ButtonPressed(PSB_PAD_DOWN)) {

Serial.println(“PAD_DOWN just pressed”);

MOTORBACK;

EnableRockerL = 0;

}else if(ps2x.ButtonReleased(PSB_PAD_DOWN)) {

Serial.println(“ PAD_DOWN just released”);

MOTORSTOP;

EnableRockerL = 1;

LStop = 0;

}

if (EnableRockerL) { //Forward and Back

if (0 《= ps2x.Analog(PSS_LY) && ps2x.Analog(PSS_LY) 《= 110) {

digitalWrite(DIR, HIGH);

analogWrite(PWM, map(ps2x.Analog(PSS_LY), 0, 110, 255,0));

LStop = 0;

} else if (255 》= ps2x.Analog(PSS_LY) && ps2x.Analog(PSS_LY) 》= 140) {

digitalWrite(DIR, LOW);

analogWrite(PWM, map(ps2x.Analog(PSS_LY), 140, 255, 0,255));

LStop = 0;

} else {

if(LStop == 0){

MOTORSTOP;

LStop ++;

}

}

}

if (ps2x.ButtonPressed(PSB_CIRCLE)) { //will be TRUE if button was JUST pressed

Serial.println(“Circle just pressed”);

TURNRIGHT;

EnableRockerR = 0;

} else if (ps2x.ButtonReleased(PSB_CIRCLE)) {

Serial.println(“Circle just released”);

TURNMID;

EnableRockerR = 1;

RMid = 0;

}

if (ps2x.ButtonPressed(PSB_SQUARE)) { //will be TRUE if button was JUST released

Serial.println(“Square just pressed”);

TURNLEFT;

EnableRockerR = 0;

} else if (ps2x.ButtonReleased(PSB_SQUARE)) { //will be TRUE if button was JUST released

Serial.println(“Square just released”);

TURNMID;

EnableRockerR = 1;

RMid = 0;

}

if (EnableRockerR) { //Left and Right

if (0 《= ps2x.Analog(PSS_RX) && ps2x.Analog(PSS_RX) 《= 110) {

myservo.write(map(ps2x.Analog(PSS_RX), 0, 110, 40,90));

RMid = 0;

} else if (255 》= ps2x.Analog(PSS_RX) && ps2x.Analog(PSS_RX) 》= 140) {

myservo.write(map(ps2x.Analog(PSS_RX), 140, 255, 90,130));

RMid = 0;

}else {

if(RMid == 0){

TURNMID;

RMid ++;

}

}

}

if (ps2x.NewButtonState(PSB_CROSS)) { //will be TRUE if button was JUST pressed OR released

Serial.println(“X just changed”);

MOTORSTOP;

}

delay(50);

}

void setMotor(int Speed) //Motor drive function

{

if (Speed 》 0)

{

digitalWrite(DIR, HIGH);

analogWrite(PWM, Speed);

}

else if(Speed 《 0){

digitalWrite(DIR, LOW);

analogWrite(PWM, -Speed);

}else{

digitalWrite(PWM, LOW);

digitalWrite(DIR, LOW);

}

}

步骤13:RC接收器(FS-TH9X)

如果使用模型遥控器,则可以按以下方式控制机器人。我只是用中断编写了一些代码,如果需要,您可以对其进行改进并使其更好。我正在使用FS-TH9X。我正在使用左右油门。为了返回,我使用右操纵杆来控制机器人的前进和后退运动。当我居中时,我停下来。左操纵杆控制左右转向。对我来说,它可能会被使用。不习惯,如果您需要FS-TH9X信息,请Google。

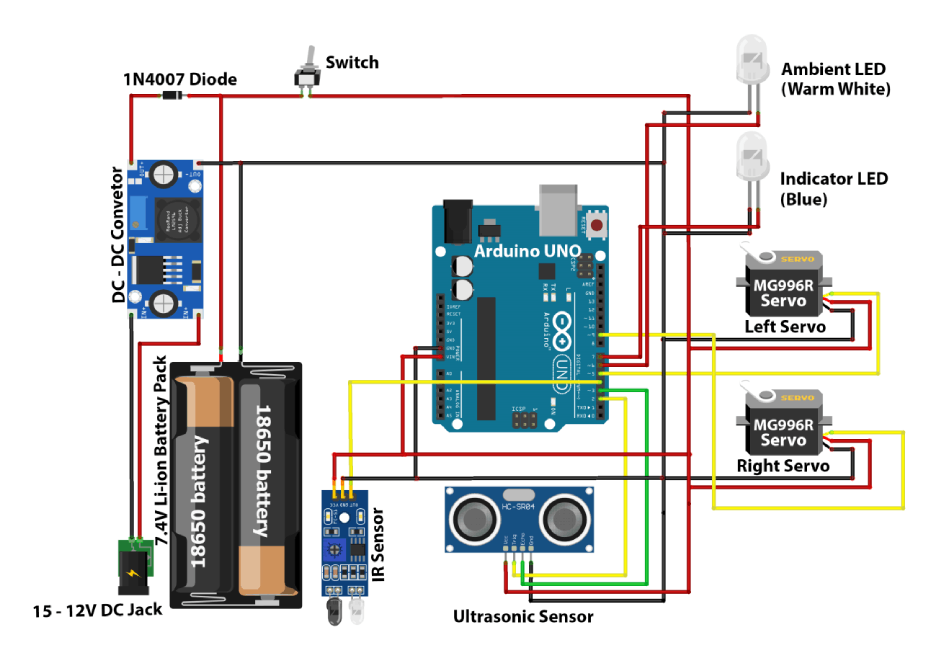

我使用CH3(油门)和CH4(方向)。接线时易于使用。可以为接收器提供5v和GND。使用Arduino UNO上的5V引脚。也许UNO可能提供的不足。该电流用于维持接收器和伺服器的正常运行。此时,您需要一个外部电源为伺服器或接收器供电。当然,您需要接地。

布线:

CH3 》》 Arduino I/O2

CH4 》》 Arduino I/O3

//The two channels of the receiver are connected to the

//digital port 2 and 3 of the arduino respectively.

int ppm1 = 2;

int ppm2 = 3;

unsigned long rc1_PulseStartTicks,rc2_PulseStartTicks;

volatile int rc1_val, rc2_val;

void setup() {

Serial.begin(9600);

pinMode(ppm1, INPUT); //PPM inputs from RC receiver

pinMode(ppm2, INPUT);

attachInterrupt(0, rc1, CHANGE); // Level change trigger interrupt

attachInterrupt(1, rc2, CHANGE);

}

void rc1(){

// did the pin change to high or low?

if (digitalRead( ppm1 ) == HIGH)

rc1_PulseStartTicks = micros(); // store the current micros() value

else

rc1_val = micros() - rc1_PulseStartTicks;

}

void rc2(){

// did the pin change to high or low?

if (digitalRead( ppm2 ) == HIGH)

rc2_PulseStartTicks = micros();

else

rc2_val = micros() - rc2_PulseStartTicks;

}

void loop() {

Serial.print(“CH1: ”);Serial.print(rc1_val); Serial.print(“ ”);//print values

Serial.print(“CH2: ”);Serial.println(rc2_val);

delay(200);

}

记住在控制时先打开发射机

#include

Servo myservo;

//The two channels of the receiver are connected to the digital port 2 and 3 of the arduino respectively.

int ppm1 = 2;

int ppm2 = 3;

int servo = 4; //Servo pin

int PWM = 5; //Motor pin

int DIR = 6; //Motor pin

unsigned long rc1_PulseStartTicks,rc2_PulseStartTicks;

volatile int rc1_val, rc2_val;

void setup() {

Serial.begin(9600);

pinMode(DIR ,OUTPUT);

pinMode(PWM ,OUTPUT);

myservo.attach(servo);

pinMode(ppm1, INPUT); //PPM inputs from RC receiver

pinMode(ppm2, INPUT);

attachInterrupt(0, rc1, CHANGE); // Level change trigger interrupt

attachInterrupt(1, rc2, CHANGE);

}

void rc1(){

// did the pin change to high or low?

if (digitalRead( ppm1 ) == HIGH)

rc1_PulseStartTicks = micros(); // store the current micros() value

else

rc1_val = micros() - rc1_PulseStartTicks;

}

void rc2(){

// did the pin change to high or low?

if (digitalRead( ppm2 ) == HIGH)

rc2_PulseStartTicks = micros();

else

rc2_val = micros() - rc2_PulseStartTicks;

}

void loop() {

if(rc1_val 《 1100){ rc1_val = 1100; }

if(rc1_val 》 1900){ rc1_val = 1900; }

if(rc2_val 《 1100){ rc2_val = 1100; }

if(rc2_val 》 1850){ rc2_val = 1850; }

if(rc1_val 》= 1100 && rc1_val 《= 1490)

{

digitalWrite(DIR ,LOW);

analogWrite(PWM,map(rc1_val,1100,1490,255,0));

}

else if(rc1_val 》= 1510 && rc1_val 《= 1900)

{

digitalWrite(DIR ,HIGH);

analogWrite(PWM,map(rc1_val,1510,1900,0,255));

}else{

digitalWrite(PWM, LOW);

digitalWrite(DIR, LOW);

}

if(rc2_val 》= 1100 && rc2_val 《= 1490)

{

myservo.write(map(rc2_val,1100,1490,40,89));

}

else if(rc2_val 》= 1510 && rc2_val 《= 1850)

{

myservo.write(map(rc2_val,1510,1850,91,130));

}

delay(15);

}

责任编辑:wv

-

遥控车

+关注

关注

9文章

81浏览量

23713 -

Arduino

+关注

关注

188文章

6469浏览量

186969

发布评论请先 登录

相关推荐

虹科免拆诊断 | 2017款捷豹F-PACE车发动机偶尔怠速不稳

虹科免拆诊断 | 2016款福特蒙迪欧车发动机怠速不稳

2012 款捷豹 XJ 车发动机怠速轻微抖动

虹科免拆诊断 | 2012 款大众速腾车发动机偶尔抖动

凤凰动力-AGV差速驱动轮的工作原理

虹科免拆诊断 | 2006 款林肯领航员车发动机怠速抖动

双电机项目,单侧电机转向改变后、重新输出时有鸣叫声是怎么回事?

如何制作自己的Arduino电容计

差速器工作原理 差速器的传动特点是差速不差力对吗

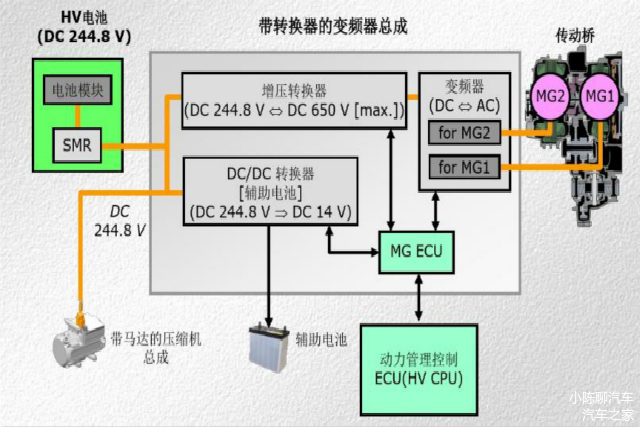

带转向器的逆变器总成的结构介绍

带Arduino的差速转向车的制作教程

带Arduino的差速转向车的制作教程

评论