KUKA电伺服机器人焊点位置补偿示意图:

GLOBALDEF Initialize (TEACH_POS : IN,cont:IN )初始化

初始化示教位置

DECLE6Pos TEACH_POS

DECL SG_Cont_T cont

CONTINUE

$ADVANCE = 3

SG_ExtaxActive=ServoGun[SG_ActiveGunNumber].ExtAxNumber

SG_ActiveWeldTimer =ServoGun[SG_ActiveGunNumber].WeldTimerIndex

bckupSetSG_AxVal()

–获得当前点的外部轴速度加速度—逼近$APO.CPTP和提前运行$RED_VEL

SGE_InitErrorHandler()

IF(ServoGun[SG_ActiveGunNumber].ExtAxNumber>0)then

SGA_SensorReset()

ENDIF

; ------初始化点-----------

P_Part=SGL_CALC_POS(TEACH_POS, ServoGun[SG_ActiveGunNumber].TipCorrection, 0)----获得焊接点位置

P_Approx=P_Part 位置转移/传输

P_Forcelim=P_Part 位置转移/传输

P_Pressure=P_Part

P_Weld=P_Part焊接位置

P_Ret=P_Part

SG_SpotHelper=P_Part

SG_PartPos = SGL_GET_AXIS_VALUE(TEACH_POS); 力模式下可能的极板接触位置

END;

GLOBALDEFFCTE6POS SGL_CALC_POS(CURRENT_POS :IN, TipCorrection:IN, TouchDiff:IN)

TouchDiff=0 执行焊接时

CURRENT_POS = TEACH_POS

TipCorrection = ServoGun[SG_ActiveGunNumber].TipCorrection=true电极校正

SGL_CALC_START_POS

REAL TouchDiff, wearflex, wearfix, TouchOffset

E6POS CURRENT_POS,RETURNED_POS

BOOL TipCorrection

IF(TipCorrection)THEN TipCorrection=true电极校正

wearflex = SG_WearFlex[SG_ActiveGunNumber] +SG_TipSeating_mm[SG_ActiveGunNumber]

wearflex弯曲磨损量由铣削后测量出来, SG_TipSeating_mm[1]电极坐值

wearfix = SG_WearFix[SG_ActiveGunNumber] +(SG_TipSeating_mm[SG_ActiveGunNumber]/2)

wearfix磨损修复由铣削后测量出来

ELSE ---没有使用校正

wearflex=0.0

wearfix= 0.0

ENDIF

X方向的补偿改变坐标 –使用BASE坐标

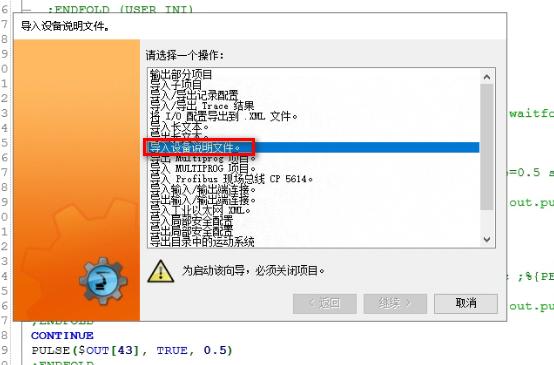

SG_Helpframe=SGL_CALC_TCP_POS(TouchDiff,wearfix) ---计算位置值

RETURNED_POS=CURRENT_POS:SG_Helpframe-----补偿值X方向的坐标

转移外部轴和S,T坐标值,用来没有激活外部轴时

RETURNED_POS.E1=CURRENT_POS.E1

RETURNED_POS.E2=CURRENT_POS.E2

RETURNED_POS.E3=CURRENT_POS.E3

RETURNED_POS.E4=CURRENT_POS.E4

RETURNED_POS.E5=CURRENT_POS.E5

RETURNED_POS.E6=CURRENT_POS.E6

RETURNED_POS.S=CURRENT_POS.S

RETURNED_POS.T=CURRENT_POS.T

TouchOffset =(wearflex+wearfix-TouchDiff)* SG_ClosingAxDir

计算偏差值

SG_ClosingAxDir=-1

TouchDiff=0 执行焊接时

Wearflex 弯曲磨损

Wearfix 电极磨损

改变补偿焊接点的外部轴E1

SWITCH SG_ExtaxActive SG_ExtaxActive=1

Case 1

RETURNED_POS.E1=CURRENT_POS.E1+TouchOffset

Case 2

RETURNED_POS.E2=CURRENT_POS.E2+TouchOffset

Case 3

RETURNED_POS.E3=CURRENT_POS.E3+TouchOffset

Case 4

RETURNED_POS.E4=CURRENT_POS.E4+TouchOffset

Case 5

RETURNED_POS.E5=CURRENT_POS.E5+TouchOffset

Case 6

RETURNED_POS.E6=CURRENT_POS.E6+TouchOffset

ENDSWITCH

RETURN (RETURNED_POS) 反馈返回坐标值

ENDFCT;

GLOBALDEFFCTE6POS SGL_CALC_TCP_POS(touchDiff:IN, wearFix:IN)

计算补偿值touchDiff=0, wearFix电极磨损

SGL_CALC_TCP_START_POS

REAL touchDiff, wearFix

E6POS RETURN_HELPFRAME

DECL SG_DIRECTIONTYP_T realDirectio

RETURN_HELPFRAME=$NULLFRAME坐标清0

realDirection = ServoGun[SG_ActiveGunNumber].GunDirection

GunDirection #PX --枪移动方向

IF((FDAT_ACT.IPO_FRAME == #TCP) AND SG_RevFixedGunDirection)THEN

-------------- FDAT_ACT.IPO_FRAME=#BASE 所以此IF语句暂时不执行-------

realDirection =SG_RevToolDirection(ServoGun[SG_ActiveGunNumber].GunDirection)

ENDIF

--------------end---------------------

SWITCH realDirection realDirection=#PX

CASE #NX

RETURN_HELPFRAME.X=-wearFix+touchDiff

CASE #NY

RETURN_HELPFRAME.Y=-wearFix+touchDiff

CASE #NZ

RETURN_HELPFRAME.Z=-wearFix+touchDiff

CASE #PX----------本次机器人执行的补偿数据touchDiff=0

RETURN_HELPFRAME.X=wearFix-touchDiff 直接用磨损值来补偿X方向

CASE #PY

RETURN_HELPFRAME.Y=wearFix-touchDiff

CASE #PZ

RETURN_HELPFRAME.Z=wearFix-touchDiff

ENDSWITCH

RETURN (RETURN_HELPFRAME)

ENDFCT

-

KUKA

+关注

关注

3文章

217浏览量

16632 -

伺服机器人

+关注

关注

0文章

5浏览量

3834

原文标题:电伺服USER程序位置补偿分析

文章出处:【微信号:gh_a8b121171b08,微信公众号:机器人及PLC自动化应用】欢迎添加关注!文章转载请注明出处。

发布评论请先 登录

相关推荐

KUKA电伺服机器人焊点位置补偿

KUKA电伺服机器人焊点位置补偿

评论