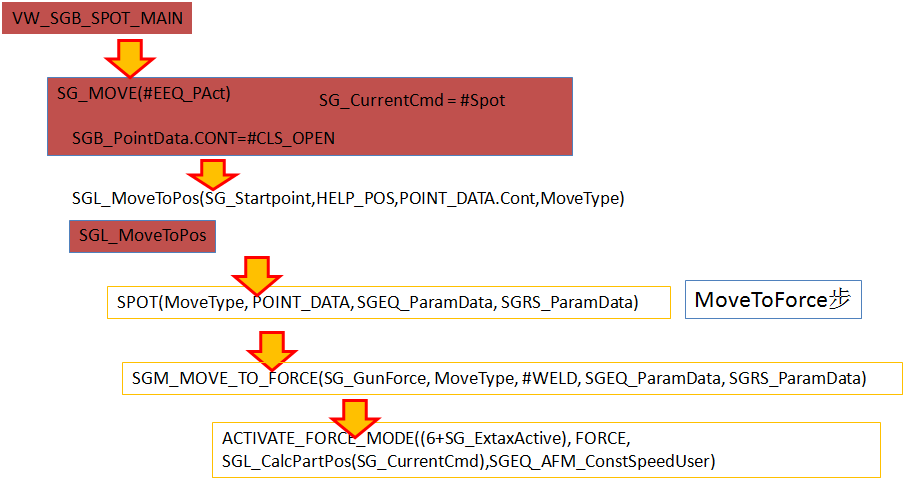

SPOT(MoveType, POINT_DATA, SGEQ_ParamData, SGRS_ParamData) 焊接控制时序

DEF SPOT (MoveType:IN, PointData:IN, SGEQ_ParamData:IN, SGRS_ParamData:OUT )

MoveType:移动类型 PTP

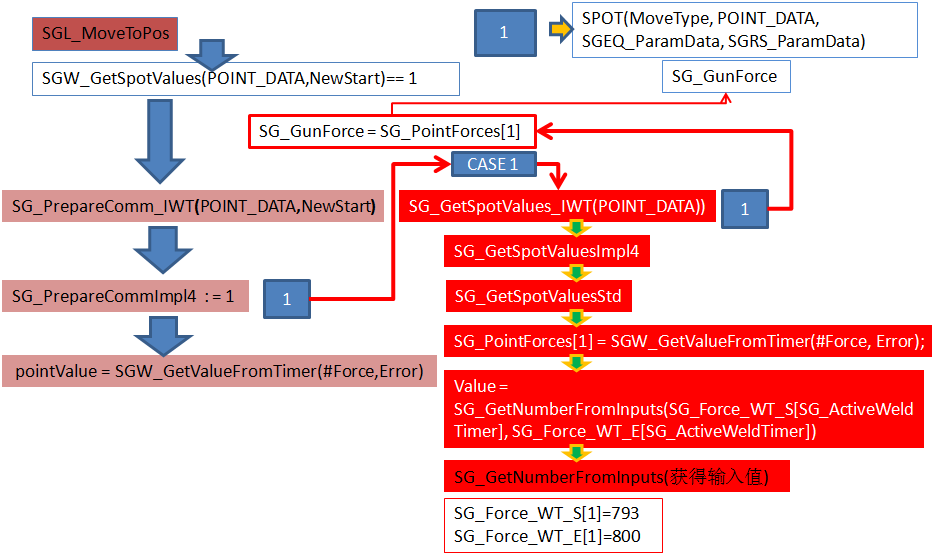

PointData: 焊点的数据:

SG_POINT_Default={Name[]"SG1",GNumber 1,Thickness 0.0,ThicknessTol 0.0,ForceProfile[]"none",ForceMode #SINGLE,Force 0.0,WeldTime 0.0,Force2 0.0,Comp#NO,Path 2.30000,PrNumber 1,MoveApprox TRUE,MaxRestart 5,Cont#NO,KeepForceAtWelding FALSE}

SGEQ_ParamData: 平衡控制的数据

CASE #MEDIUM

EEQ_PAct.MODE = EQMode

EEQ_PAct.TimeExpectedFactor = 75

EEQ_PAct.Push_ThresholdFactor = 100

EEQ_PAct.Push_ReduceTorqueFactor = 100

SGEQ_StartForceFactor =100

SGRS_ParamData: 暂时不用

SPOT准备点:

retry = FALSE 初始化变量重试功能

IF(SG_MaxRestart== 0)THEN SG_MaxRestart=3

SG_MaxRestart = ServoGun[1].MaxRestart=3重复次数

RetryMaxReached = TRUE 重试达到的最大

ELSE

RetryMaxReached = FALSE

ENDIF

NewStart = FALSE

SpotSteps=checkwear 检查磨损步

REPEAT 开始执行循环

IF((retry) AND (SpotSteps == endSpot))THEN

重试功能被激活, SpotSteps == endSpot在结束步

RetryMaxReached = SpotCountRetry()重复计数重试>3重试达到的最大

SpotSteps = checkwear 去检查磨损步

retry = FALSE 关闭重试

ENDIF

SWITCH SpotSteps

CASE checkwear 检查磨损

SGL_HandleCheckWear(SGL_CheckWear(), SpotSteps, checkNoPartIn, checkNoPartIn, 0, endspot, errorRetry, RetryMaxReached)

检查电极是否满足要求,正常情况去下一步checkNoPartIn

IF(SpotSteps == errorRetry)THEN 如果需要去错误重试步

retry = TRUE 激活重试

ENDIF

CASE checkNoPartIn 检查没有零件

IF(ServoGun[SG_ActiveGunNumber].CompType == #AIR)THEN

设置规定CompType #EQUALIZING平衡技术,因此这段程序不执行

SG_DECL_COMP_INTERRUPT (PointData.Comp,PointData.Cont)

ENDIF

IF(SGL_ReadIn(SG_NoPart,FALSE))THEN

SG_NoPart=0, 读入E0=0,检验位SGL_ReadIn反馈false

SG_NoPart_ER = TRUE

SG_MainErrorHandlTyp = #MainWithNotify

returnUnused = SGE_MainAndSubmitMsg_ER (FALSE)

SpotSteps = reposition 去返回原位

ELSESGL_ReadIn反馈false执行下一步检查枪力

SpotSteps = checkGunForceLim 执行下一步检查枪力

ENDIF

CASE checkGunForceLim 检查枪力极最小限值

CONTINUE

IF(NOT ((SG_GunForce)<=$FORCE_LIM[(6+SG_ExtaxActive)]))THEN

SG_ExtaxActive=1 激活的外部轴1$FORCE_LIM 力最小极限值,这段的意思是给入的力值不能小于系统极限值.

SpotSteps = checkGunForceMax去检查力是否超出最大值

ELSE 如果小于最小值

SG_ForceLowerFlim_ER=TRUE 小于最小值故障报警

SG_MainErrorHandlTyp = #MainWithDlg

SpotSteps =SGL_DlgAnsOrMsgLineSel(FALSE, reposition,,RetryMaxReached) 需要跳到回到原位步

ENDIF

CASE checkGunForceMax 检查枪力是否超出最大值

CONTINUE

IF(NOT ((SG_GunForce)>$FORCE_MAX[(6+SG_ExtaxActive)]))THEN

SG_ExtaxActive=1 激活的外部轴1$FORCE_MAX 力最大极限值,这段的意思是给入的力值不能大于系统极限值.

SpotSteps = checkSpinTime 去检查旋转时间步

ELSE 否则

SG_ForceHigherFmax_ER=TRUE大于最大值故障报警

SG_MainErrorHandlTyp = #MainWithDlg

SpotSteps = SGL_DlgAnsOrMsgLineSel (FALSE, reposition,,RetryMaxReached)需要跳到故障复位步

ENDIF

CASE checkSpinTime ;检查旋转时间-机器人旋转选项已启用(机器人没有使用此功能)

IF(SG_RobospinInstalled) AND SGRS_Active AND NOT (SGRS_ParamData.SpinTyp== #OFF)THEN

SG_RobospinInstalled=FALSE 控制器没有安装机器人旋转.因此以下程序很多将不执行.

IF(SGRS_ParamData.SpinAngle == 0)THEN

SGRS_ParamData.SpinTyp = #OFF

SGRS_AngleZero_ER = TRUE

SG_MainErrorHandlTyp = #MainWithNotify

returnUnused =SGE_MainAndSubmitMsg_ER (FALSE)

ENDIF

IF((SGRS_ParamData.SpinTimeSource == #WELDTIMER) AND (SGRS_ParamData.SpinTyp== #DURING))THEN

SGRS_ParamData.SpinTime = 0

FOR i = 1 TO(SG_ForceCountMax-1);多力验证

IF(SG_PointForcesTime[i] < 10)THEN;检查时间是以秒还是毫秒为单位 SG_PointForcesTime[i] =SG_PointForcesTime[i] * 1000

ENDIF

SGRS_ParamData.SpinTime =SGRS_ParamData.SpinTime + SG_PointForcesTime[i]

ENDFOR

SGRS_ParamData.SpinTime =SGRS_ParamData.SpinTime + SGRS_ParamData.TimeOffset

IF NOT (SGRS_ParamData.SpinTime < 0 )THEN

SpotSteps =ActivateTorqSafety

ELSE

SGRS_TimeToLow_ER=TRUE

SG_MainErrorHandlTyp = #MainWithDlg

SpotSteps =SGL_DlgAnsOrMsgLineSel (FALSE, reposition,,RetryMaxReached)

ENDIF

ELSE

SpotSteps =ActivateTorqSafety

ENDIF

ELSE 如果没有使用运转功能就去下一步“启动焊接安全”

SpotSteps = ActivateTorqSafety

ENDIF

CASE ActivateTorqSafety启动焊接安全

SGL_TorqueOn () 扭矩检查扭矩,用以保护枪设置极限机器人扭矩值

SpotSteps = resetCompensation 去重置补偿步

CASE resetCompensation重置补偿,跳过

IF(ServoGun[SG_ActiveGunNumber].CompType== #AIR)THEN

SGL_SetCompOut(TRUE,PointData.Comp) CompType=#EQUALIZING平衡技术

ENDIF

SpotSteps = PrepareMoveToForce 去准备移至力值步

CASE PrepareMoveToForce准备移至力值

CONTINUE

INTERRUPTDECL SG_Interrupt21 WHEN $SG_PART_DETECTED[6+SG_ExtaxActive] == TRUE DO SG_SetPartDetected()

激活中断零件检测, $SG_PART_DETECTED[7]外部轴7轴的零件检测,被认为检测到零件

SG_PartDetected= FALSE零件检测

SGL_SaveSetSoftend (SG_PartThickness-SG_PartThicknessTol)

SG_ConstSpeed=SGL_SPEED_CALC(SG_GunForce,MoveType,TRUE)

速度计算(焊钳给入力值,运动类型PTP, 激活)

SGM_CALCULATE_POINTS(SG_GunForce,#WELD) 点计算和设定最大扭矩

IF SG_DEBUG_MeasureForce THEN

returnUnused = SGL_ForceMeanVal(TRUE)

ENDIF

SpotSteps = MoveToForce

CASE MoveToForce 移动到力量

IF(SG_ForceTraceEnable)THEN强制跟踪没有启用SG_ForceTraceEnable=FALSE

SG_StartForceTrace(SG_ActiveGunNumber)启动力追踪

ENDIF

SG_StopReaction = FALSE停止反应

-------开启中断----------

INTERRUPTON SG_Interrupt1 ; 禁止重新定位

INTERRUPTON SG_Interrupt9 ; 停止按钮

INTERRUPTON SG_Interrupt21 ; 检测分割

SG_ReposActive = FALSE 重复定位不启动

SGM_MOVE_TO_FORCE(SG_GunForce, MoveType, #WELD, SGEQ_ParamData, SGRS_ParamData) 移动到焊接轨迹点并带力移动进行夹紧

SGL_MaintenanceCounter(SG_ActiveGunNumber)维护计数器

SpotSteps = WaitPartDetected 等待零件检测到给到下一步

SGL_TimerControl(SG_TimerFCTRL,#TRestart) 开启时间监控

CASE WaitPartDetected 等待零件检测到

IF((SGEQ_ParamData.MODE<>#OFF) AND (SGEQ_Active==TRUE) AND SGEQ_ActivePointCond)THEN

SGEQ_ParamData.MODE = EQMode,平衡控制激活,活动点号SGEQ_ActivePointCond=FALSE

IF(($TIMER[SGEQ_TimerFixPos] * 0.001)> SGEQ_CurrentParameters.TIME_EXPECTED)THEN

SGEQ_StartFreeze = TRUE 开始冻结

ENDIF

ENDIF

IF(SG_PartDetected)THEN 如果检测到零件,通过中断程序检测零件

SpotSteps = ContPosChckFandThick 去检查厚度步

ELSE 如果没有检测到零件

CONTINUE

IF(($MODE_OP == #T1) OR ($OV_PRO < 50))THEN

TimeResult =SG_TimeoutTimePartDetec * 5.0

SG_TimeoutTimePartDetec 1750.0

ELSE 如果不是T1模式,速度没有小与50

TimeResult =SG_TimeoutTimePartDetec

ENDIF

---超时报警-----

IF($Timer[SG_TimerFCTRL] >= TimeResult)THEN

如果T33>=1750.0/875

SG_NoPartDetected_ER = TRUE 没有找到零件故障

SG_MainErrorHandlTyp = #MainWithDlg 手动复位报警提示

$FORCE[(6+SG_ExtaxActive)] = 0 ;力控制关闭

SGEQ_StartFreeze = TRUE

SGEQ_Stop()焊钳移动关闭

IF(NOT RetryMaxReached)THEN 如果没有达到最大重复次数

SWITCH( SGE_MainAndSubmitMsg_ER(RetryMaxReached))

CASE 1 通过提示信息反馈,是要重焊,还是去下一点

是->重试最后一点

SpotSteps = errorRetry 去错误重试步

retry = TRUE

CASE 2; 不->继续开枪->下一点

SpotSteps = disableForceMode 去关闭力模式

ENDSWITCH

ELSE 如果没有到达最大重复步,就去

SpotSteps = SGL_DlgAnsOrMsgLineSel (false, disableForceMode,,RetryMaxReached)监控计算步

ENDIF

ELSE如果没有超时就再去等待零件检测步

SpotSteps = WaitPartDetected

ENDIF

ENDIF

CASE FastVectorMoveOff快速矢量移动关闭步

ActivateFastVMVOff() 确认焊接快速夹紧

SpotSteps = ContPosChckFandThick 连续位置检查零件厚度

CASE ContPosChckFandThick连续位置检查零件厚度

SG_TriggerEnd=FALSE 触发结束

IF(SGM_ChkForcePartThick(SGEQ_ParamData,TRUE,RetryMaxReached))THEN 如果计算零件厚度正确

SpotSteps = ForceReached 去力达到

ELSE 如果厚度不正确

SG_MainErrorHandlTyp = #MainWithDlg 需要手动复位

CONTINUE

IF(($MODE_OP == #T1) OR ($MODE_OP == #T2))THEN

CONTINUE

$FORCE[(6+SG_ExtaxActive)] = 0 ;关力控制

ENDIF

IF(NOT RetryMaxReached)THEN 如果没有到达力重复最大值

SWITCH( SGE_MainAndSubmitMsg_ER(RetryMaxReached))

主要并提交故障信息

CASE 1 ; 是->重试最后一点

SpotSteps = errorRetry

retry = TRUE

CASE 2 ;否->继续开枪->下一点

SpotSteps = disableForceMode去关闭力模式步

ENDSWITCH

ELSE 如果可以计算步信息

SpotSteps = SGL_DlgAnsOrMsgLineSel (false, disableForceMode,,RetryMaxReached)

ENDIF

ENDIF

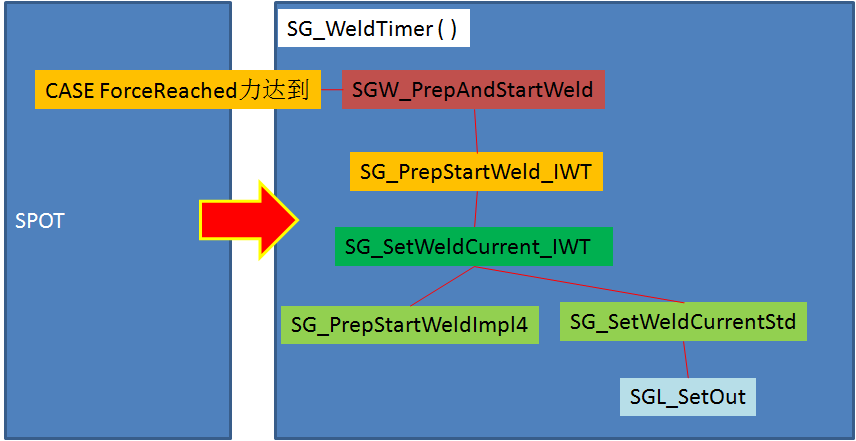

CASE ForceReached力达到

IF SG_DEBUG_MeasureForce THEN 测量力诊断暂时不用

returnUnused = SGL_ForceMeanVal(FALSE)

ENDIF

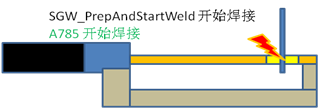

IF( SGW_PrepAndStartWeld(#WaitForReady,NewStart)== 1 )THEN

开始焊接 ,焊接结束后

SpotSteps = detectWeldEnd检测焊接结束

ELSE 如果焊接不合格

SG_TimerErrorHandlTyp = #TimerWithDlg 故障报警类型

CONTINUE

IF(($MODE_OP == #T1) OR ($MODE_OP == #T2))THEN

如果是在T1模式或者T2模式

CONTINUE

$FORCE[(6+SG_ExtaxActive)] = 0 ;关力控制

ENDIF

SGEQ_Stop() 关闭焊钳平衡移动

;水位检查

error_Water =SGE_WaterguardChecker()流量检测

IF(NOT RetryMaxReached)THEN 如果没有重试达到的最大值

IF error_Water THEN 水错误

Result =SGE_MainAndSubmitMsg_ER(RetryMaxReached)

进入机器人故障提示对话框报错: 重试达到的最大

ELSE

Result =SGE_WeldTimerMsg_ER(RetryMaxReached)

ENDIF

SWITCH Result

CASE 1 ; yes -->重试

returnUnused = SG_ResetError_IWT(#ResetDefault)恢复默认

SpotSteps = errorRetry 去故障重试步

retry = TRUE

CASE 2; no -->继续开枪->下一点

returnUnused = SG_ResetError_IWT(#ResetDefault)恢复默认

SpotSteps = disableForceMode

ENDSWITCH

ELSE

SpotSteps = SGL_DlgAnsOrMsgLineSel ((NOT error_Water), disableForceMode,,RetryMaxReached)

ENDIF

ENDIF

CASE detectWeldEnd 检测焊接结束

SG_WriteLogbook(SG_ProgramNumber, FALSE, SGEQ_ParamData)写日志书

IF(SG_RobospinInstalled AND (SGRS_ParamData.SpinTyp==#DURING) AND SGRS_Active)THEN;SG_RobospinInstalled=false机器人运行, SpinTyp= #OFF SGRS_Active=TRUE 不使用机器人旋转

IF SGEQ_ActivePointCond THEN

IF $VMSTATE.ACTIVE THEN

SGEQ_STOP()

WAIT FOR ($VMSTATE.ACTIVE ==FALSE)

ENDIF

ENDIF

SGRS_RoboSpinTurn($POS_ACT_MES,MoveType, PointData, SGRS_ParamData) ;开始机器人旋转的转弯运动

TimerResult = SGg_ResultWeldEnd

NewStart = SGg_NewStart

ELSE 不使用机器人旋转就执行下面的程序

TimerResult = SGW_GetWeldEndSignal(NewStart)E785焊接完成FK

获取焊接结束信号(重新开始)

ENDIF

IF( TimerResult == 1)THEN ;焊接控制器无错误

RoboSpinBySPS = FALSE 机器人旋转

RoboSpinBySPS = SGL_ReadIn(SG_StartRoboSpin,TRUE)

SG_StartRoboSpin=0 ,没有使用机器人旋转

IF(SG_RobospinInstalled AND (SGRS_ParamData.SpinTyp==#AFTER) ANDSGRS_Active AND RoboSpinBySPS)THEN(不使用)

-焊接后机器人旋转-SG_RobospinInstalled=FALSE SpinTyp= #OFF ,SGRS_Active=TRUE,RoboSpinBySPS = FALSE

IF(SGRS_AktCounter[SG_ActiveGunNumber] <= SGRS_TurnCount)THEN

SGRS_HelpGunForce =((100-SGRS_ParamData.PercentForce)/100)* SG_GunForce

SGRS_GunForce =SGRS_HelpGunForce

IF(SGRS_GunForce < $Force_LIM[6+SG_ExtaxActive])THEN

;目标力小于力的极限值

SGRS_GunForce = $Force_LIM[6+SG_ExtaxActive]+1

SGRS_ForceLim_ER = TRUE

returnUnused = SGE_MainAndSubmitMsg_ER (FALSE)

ENDIF

$FORCE[(6+SG_ExtaxActive)] = SGRS_GunForce 旋转力760

PTP $POS_ACT 执行当前位置

waitfor TRUE

IF SGEQ_ActivePointCond THEN

IF $VMSTATE.ACTIVE THEN

SGEQ_STOP()

WAITFOR($VMSTATE.ACTIVE == FALSE)

ENDIF

ENDIF

SGRS_RoboSpinTurn($POS_ACT_MES,MoveType, PointData, SGRS_ParamData);开始RoboSpin的转弯运动

SGRS_RoboSpinSetOpenPos()

IF($MODE_OP == #AUT) OR ($MODE_OP== #EX)THEN

SGRS_AktCounter[SG_ActiveGunNumber] = SGRS_AktCounter[SG_ActiveGunNumber] + 1

ENDIF

ENDIF

ENDIF

焊接合格后:去禁用力模式步

SpotSteps = disableForceMode, disableForceMode=140去禁用力模式步

IF(SG_RobospinInstalled AND (SGRS_ParamData.SpinTyp==#DURING) AND SGRS_Active)THENSpinTyp=OFF 机器人旋转暂时没有使用

; 焊接计时器没有错误,将新的起点设置为打开喷枪

SGRS_RoboSpinSetOpenPos()

ENDIF

ELSE焊接控制器错误,焊接不合格

SG_TimerErrorHandlTyp = #TimerWithDlg

SGEQ_Stop() 关闭平衡控制

IF(NOT RetryMaxReached)THEN

SWITCH( SGE_WeldTimerMsg_ER(RetryMaxReached))

CASE 1 ; 是,重试地点,并带有新的枪口关闭功能

SpotSteps = errorRetry 去错误重试步

retry = TRUE

returnUnused = SG_ResetError_IWT(#ResetDefault)

CASE 2 ; 不->继续开枪->下一点

returnUnused = SG_ResetError_IWT(#ResetDefault)

SpotSteps = errorRetry

retry = FALSE

CASE 3 仅重试焊缝而无需打开和关闭

returnUnused = SG_ResetError_IWT(#ResetWithRetry)

SpotSteps = ForceReached

DEFAULT

REPEAT

MsgNotify("Unexpectedanswer from weld timer, program running must be stopped.")焊接计时器的意外应答,必须停止程序运行

HALT

UNTIL FALSE

ENDSWITCH

ELSE

SpotSteps =SGL_DlgAnsOrMsgLineSel (TRUE, disableForceMode,,RetryMaxReached) ---计算步去力关闭步

ENDIF

ENDIF

CASE disableForceMode 关闭力模式

IF(SG_PointDataAct.KeepForceAtWelding)THEN

KeepForceAtWelding=FALSE保持焊接力

RESET_TORQUE_LIMITS(6+SG_ExtaxActive)复位扭矩极限E1焊钳

waitsec 0.0

ENDIF

CONTINUE

$FORCE[(6+SG_ExtaxActive)] = 0 ;关断力控制

CONTINUE

;$APO.CPTP=1

INTERRUPTOFF SG_Interrupt1 ; 禁用抑制重新定位

INTERRUPTOFF SG_Interrupt9 ; 停止按钮

INTERRUPTOFF SG_Interrupt21

SpotSteps = reposition去回到原位步

CASE errorRetry 错误重试

INTERRUPTOFF SG_Interrupt1 ; 禁用抑制重新定位

INTERRUPTOFF SG_Interrupt9 ; 停止按钮

INTERRUPTOFF SG_Interrupt21

$FORCE[(6+SG_ExtaxActive)] = 0 ;关断力控制

IF(SG_PointDataAct.KeepForceAtWelding)THEN

保持焊接力KeepForceAtWelding =false

RESET_TORQUE_LIMITS(6+SG_ExtaxActive)重置扭矩极限

waitsec 0.0

ENDIF

TRIGGERWHENDISTANCE= 1 DELAY= 0 DO SGL_ResetSoftEnd(SG_ActiveGunNumber)PRIO=-1

因为有焊接故障,重新移动到打开位置

IF((ServoGun[SG_ActiveGunNumber].CompType==#EQUALIZING) AND (SGEQ_ParamData.Mode<>#OFF) AND (SGEQ_Active==TRUE))THEN

CompType=#EQUALIZING使用平衡控制. MODE = EQMode,平衡控制激活

SGEQ_Stop();如果上次尝试仍将其关闭,请关闭矢量移

SGL_MoveToPos(SGEQ_StartPoint,SGEQ_StartPoint,#NO,#SG_LIN)

ELSE

SGL_MoveToPos(P_APPROX,P_APPROX,#NO,MoveType)

ENDIF

----X轴没有补偿

IF ServoGun[SG_ActiveGunNumber].XCompActive THEN XCompActive=FALSE

SWITCH MoveType

CASE #SG_PTP, #SG_LIN ,#SG_CIRC

SGL_MoveToPos(SG_Startpoint,SG_Startpoint,#NO,#SG_LIN)

CASE #SG_SPTP, #SG_SLIN ,#SG_SCIRC

SGL_MoveToPos(SG_Startpoint,SG_Startpoint,#NO,#SG_SLIN)

ENDSWITCH

ENDIF

SpotSteps = reposition去回到原位

CASE reposition 回到原位

SGL_TorqueOff() 转矩控制关闭

IF((ServoGun[SG_ActiveGunNumber].CompType==#EQUALIZING) AND (SGEQ_ParamData.Mode<>#OFF) AND (SGEQ_Active==TRUE))THEN

SGEQ_Stop();停止焊枪平衡控制.如果上次尝试仍将其关闭,请关闭向量移动

ENDIF

IF(ServoGun[SG_ActiveGunNumber].CompType == #AIR)THEN

焊钳平衡控制不使用空气控制 CompType==#EQUALIZING

SWITCH SG_ExtaxActive

CASE 1

IF(SG_ClosingAxDir<0)THEN

IF($AXIS_ACT.E1>=SG_TriggerCompPos)THEN

SGL_COMPENSATOR()

ELSE

INTERRUPTON SG_Interrupt11

ENDIF

ELSE

IF($AXIS_ACT.E1<=SG_TriggerCompPos)THEN

SGL_COMPENSATOR()

ELSE

INTERRUPTON SG_Interrupt11

ENDIF

ENDIF

CASE 2

IF(SG_ClosingAxDir<0)THEN

IF($AXIS_ACT.E2>=SG_TriggerCompPos)THEN

SGL_COMPENSATOR()

ELSE

INTERRUPTON SG_Interrupt11

ENDIF

ELSE

IF($AXIS_ACT.E2<=SG_TriggerCompPos)THEN

SGL_COMPENSATOR()

ELSE

INTERRUPTON SG_Interrupt11

ENDIF

ENDIF

CASE 3

IF(SG_ClosingAxDir<0)THEN

IF($AXIS_ACT.E3>=SG_TriggerCompPos)THEN

SGL_COMPENSATOR()

ELSE

INTERRUPTON SG_Interrupt11

ENDIF

ELSE

IF($AXIS_ACT.E3<=SG_TriggerCompPos)THEN

SGL_COMPENSATOR()

ELSE

INTERRUPTON SG_Interrupt11

ENDIF

ENDIF

CASE 4

IF(SG_ClosingAxDir<0)THEN

IF($AXIS_ACT.E4>=SG_TriggerCompPos)THEN

SGL_COMPENSATOR()

ELSE

INTERRUPTON SG_Interrupt11

ENDIF

ELSE

IF($AXIS_ACT.E4<=SG_TriggerCompPos)THEN

SGL_COMPENSATOR()

ELSE

INTERRUPTON SG_Interrupt11

ENDIF

ENDIF

CASE 5

IF(SG_ClosingAxDir<0)THEN

IF($AXIS_ACT.E5>=SG_TriggerCompPos)THEN

SGL_COMPENSATOR()

ELSE

INTERRUPTON SG_Interrupt11

ENDIF

ELSE

IF($AXIS_ACT.E5<=SG_TriggerCompPos)THEN

SGL_COMPENSATOR()

ELSE

INTERRUPTON SG_Interrupt11

ENDIF

ENDIF

CASE 6

IF(SG_ClosingAxDir<0)THEN

IF($AXIS_ACT.E6>=SG_TriggerCompPos)THEN

SGL_COMPENSATOR()

ELSE

INTERRUPTON SG_Interrupt11

ENDIF

ELSE

IF($AXIS_ACT.E6<=SG_TriggerCompPos)THEN

SGL_COMPENSATOR()

ELSE

INTERRUPTON SG_Interrupt11

ENDIF

ENDIF

ENDSWITCH

ENDIF

SpotSteps = endSpot步结束

ENDSWITCH

UNTIL((SpotSteps == endSpot) AND ((retry == FALSE) OR (RetryMaxReached)))

结束循环控制的条件: 在结束步并且没有重复,或者重复次数达到最大值

END;

-

焊接

+关注

关注

38文章

3240浏览量

60218 -

伺服

+关注

关注

16文章

655浏览量

41128 -

KUKA

+关注

关注

3文章

217浏览量

16630

原文标题:KUKA电伺服焊钳USER程序SPOT 焊接点时序编程分析

文章出处:【微信号:gh_a8b121171b08,微信公众号:机器人及PLC自动化应用】欢迎添加关注!文章转载请注明出处。

发布评论请先 登录

相关推荐

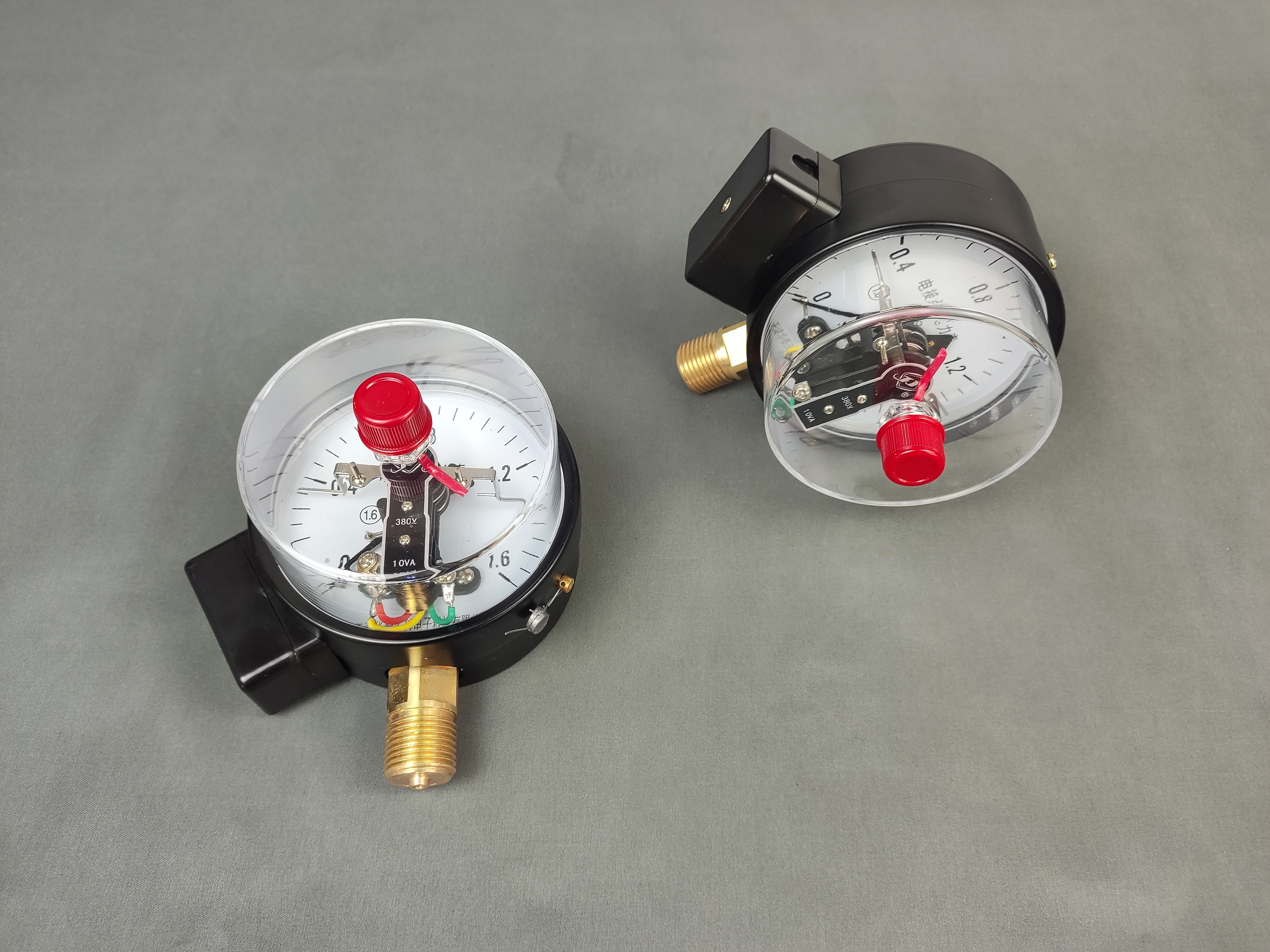

电接点压力表有哪些常见故障

罗技发布粘贴式雷达传感器Logitech Spot

AN-0973: 超级时序控制器的EEPROM擦除和编程

不同材料间的焊接冶金特性

按照TAS5711的datasheet中的上电时序进行上电,芯片正常工作,但是无法编辑寄存器,是时序有问题吗?

时序逻辑电路故障分析

轻松实现复杂的电源时序控制

交流伺服电机与直流伺服电机的对比分析

FPGA 高级设计:时序分析和收敛

伺服压力机的优缺点分析

伺服驱动器不上电是什么原因

plc控制伺服驱动器编程实例介绍

LED模组灯珠焊接点推拉力测试机应用案例

KUKA电伺服焊钳USER程序SPOT焊接点时序编程分析

KUKA电伺服焊钳USER程序SPOT焊接点时序编程分析

评论