Nanodcal是一款基于非平衡态格林函数-密度泛函理论(NEGF - DFT)的第一性原理计算软件,主要用于模拟器件材料中的非线性、非平衡的量子输运过程,是目前国内唯一一款拥有自主知识产权的基于第一性原理的输运软件。可预测材料的电流 - 电压特性、电子透射几率等众多输运性质。

迄今为止,Nanodcal 已成功应用于1维、2维、3维材料物性、分子电子器件、自旋电子器件、光电流器件、半导体电子器件设计等重要研究课题中,并将逐步推广到更广阔的电子输运性质研究的领域。

本期将给大家介绍Nanodcal自旋器件1.3.2-1.3.3的内容。

1.3.2 镍/黑磷/镍隧道结的电输运

1.3.2.1 计算模型

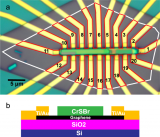

用户可参考第一部分Device Studio建模的过程,自行搭建Ni(111)和Ni(100)MTJs。图2-1给出了本章研究所采用的计算模型即Ni(111)/MBP/Ni(111)及Ni(100)/MBP/Ni(100) MTJs。这种结构是一个开放式双电极体系,由三个部分组成,分别为左电极、中心区、右电极。Ni(111)/MBP/Ni(111)及Ni(100)/MBP/Ni(100)隧道结在x方向具有周期性,分别为4.316Å和3.524Å,y方向是输运方向。图2-28(e,f,g)分别为黑磷结构的俯视图和侧视图, 晶格常数为a=4.58Å,b=3.32Å。MBP的a或b拉伸±6%后,与Ni/MBP/Ni隧道结的x方向的晶格常数相匹配。通过结构优化,得到Ni(111)、Ni(100)基底表面与黑磷的最佳距离分别为2.0Å、1.95Å。

1.3.2.2 输运计算

PC代表平行结构,APC代表反平行结构。由于体系较大,推荐使用服务器进行计算。

1.3.2.2.1 自洽计算(平衡态下)

以平行结构Ni(111)/MBP/Ni(111)为例:

A.电极自洽计算-PC

(1)准备输入文件:scf.input;基组文件Ni_LDA-DZP.nad,PNi_LDA-DZP.nad

%%What quantities should be calculatedcalculation.name = scf%Basic settingcalculation.occupationFunction.temperature = 100calculation.realspacegrids.E_cutoff = 80 Hartreecalculation.xcFunctional.Type = LDA_PZ81calculation.k_spacegrids.number = [ 100 1 1 ]'system.centralCellVectors = [[2.4918 0 0]' [0 4.316 0]' [0 0 25]']system.spinType = CollinearSpin%Iteration controlcalculation.SCF.monitoredVariableName = {'rhoMatrix','hMatrix','totalEnergy','bandEnergy','gridCharge','orbitalCharge','spinPolar'}calculation.SCF.convergenceCriteria = {1e-04,1e-04,[],[],[],[],[]}calculation.SCF.maximumSteps = 200calculation.SCF.mixMethod = Pulaycalculation.SCF.mixRate = 0.1calculation.SCF.mixingMode = Hcalculation.SCF.startingMode = H%calculation.SCF.donatorObject = NanodcalObject.mat%Basic setsystem.neutralAtomDataDirectory = '../'system.atomBlock = 10AtomType OrbitalType X Y Z SpinPolarizationNi LDA-DZP 1.86888322 3.95633418 14.51182073 0.3Ni LDA-DZP 0.62296107 1.79833372 14.51182073 0.3Ni LDA-DZP 1.86888322 2.51766721 12.47723838 0.3Ni LDA-DZP 0.62296107 0.35966675 12.47723838 0.3Ni LDA-DZP 1.86888322 1.07900023 10.44265604 0.3Ni LDA-DZP 0.62296107 3.23700070 10.44265604 0.3Ni LDA-DZP 1.86888322 3.95633418 40807369 0.3Ni LDA-DZP 0.62296107 1.79833372 40807369 0.3Ni LDA-DZP 1.86888322 2.51766721 6.37349134 0.3Ni LDA-DZP 0.62296107 0.35966675 6.37349134 0.3end

(2)自洽计算:连接服务器(请参见Device Studio的工具栏中help→help Topic→7.应用实例→7.1Nanodcal实例)在选择服务器后,选中scf.input右击run。等待计算完毕后点击JobManager所示界面中的Action下的下载按钮下载NanodcalObject.mat文件。

B.中心区的自洽计算-PC

(1)准备输入文件:scf.input;基组文件Ni_LDA-DZP.nad,PNi_LDA-DZP.nad

%%What quantities should be calculatedcalculation.name = scf%Basic settingcalculation.occupationFunction.temperature = 100calculation.realspacegrids.E_cutoff = 80 Hartreecalculation.xcFunctional.Type = LDA_PZ81calculation.k_spacegrids.number = [ 1 1 1 ]'%Description of electrodesystem.numberOfLeads = 2system.typeOfLead1 = frontsystem.voltageOfLead1 = 0system.objectOfLead1 = ../FrontElectrode/NanodcalObject.matsystem.spinDirectionOfLead1 = [0 0 1] %电极1的自旋方向system.typeOfLead2 = backsystem.voltageOfLead2 = 0system.objectOfLead2 = ../BackElectrode/NanodcalObject.matsystem.spinDirectionOfLead2 = [0 0 1] %电极2的自旋方向%Contour integral%calculation.complexEcontour.lowestEnergyPoint = 1.5 Hartreecalculation.complexEcontour.numberOfPoints = 40calculation.realEcontour.interval = 0.0272114calculation.realEcontour.eta = 0.0272114system.centralCellVectors = [[46563 0 0]' [0 4.316 0]' [0 0 25]']system.spinType = CollinearSpin%Iteration controlcalculation.SCF.monitoredVariableName = {'rhoMatrix','hMatrix','totalEnergy','bandEnergy','gridCharge','orbitalCharge','spinPolar'}calculation.SCF.convergenceCriteria = {1e-04,1e-04,[],[],[],[],[]}calculation.SCF.maximumSteps = 200calculation.SCF.mixMethod = Pulaycalculation.SCF.mixRate = 0.1calculation.SCF.mixingMode = Hcalculation.SCF.startingMode = H%calculation.SCF.donatorObject = NanodcalObject.mat%Basic setsystem.neutralAtomDataDirectory = '../'system.atomBlock = 159AtomType OrbitalType X Y Z SpinPolarizationP LDA-DZP 11.07494990 3.60404468 162650771 0.3P LDA-DZP 14.38825099 3.60404468 162650771 0.3P LDA-DZP 17.70155016 3.60404515 162650771 0.3P LDA-DZP 21.01484934 3.60404515 162650771 0.3P LDA-DZP 24.32815043 3.60404515 162650771 0.3P LDA-DZP 27.64144961 3.60404515 162650771 0.3P LDA-DZP 30.95475070 3.60404515 162650771 0.3P LDA-DZP 34.26805178 3.60404563 162650771 0.3P LDA-DZP 37.58135287 3.60404563 162650771 0.3P LDA-DZP 11.07494990 2.89895606 16.46069045 0.3P LDA-DZP 14.38824908 2.89895606 16.46069045 0.3P LDA-DZP 17.70155016 2.89895654 16.46069045 0.3P LDA-DZP 21.01484934 2.89895654 16.46069045 0.3P LDA-DZP 24.32815043 2.89895654 16.46069045 0.3P LDA-DZP 27.64144961 2.89895558 16.46069045 0.3P LDA-DZP 30.95475070 2.89895558 16.46069045 0.3P LDA-DZP 34.26805178 2.89895606 16.46069045 0.3P LDA-DZP 37.58135287 2.89895606 16.46069045 0.3P LDA-DZP 9.41830031 1.41704440 16.46069045 0.3P LDA-DZP 12.73160044 1.41704440 16.46069045 0.3P LDA-DZP 16.04489962 1.41704488 16.46069045 0.3P LDA-DZP 19.35819880 1.41704488 16.46069045 0.3P LDA-DZP 22.67149989 1.41704488 16.46069045 0.3P LDA-DZP 25.98480097 1.41704488 16.46069045 0.3P LDA-DZP 29.29810015 1.41704488 16.46069045 0.3P LDA-DZP 32.61140124 1.41704488 16.46069045 0.3P LDA-DZP 35.92469851 1.41704535 16.46069045 0.3P LDA-DZP 39.23799960 1.41704535 16.46069045 0.3P LDA-DZP 9.41830031 0.71195674 162650771 0.3P LDA-DZP 12.73160044 0.71195698 162650771 0.3P LDA-DZP 16.04489962 0.71195698 162650771 0.3P LDA-DZP 19.35820071 0.71195698 162650771 0.3P LDA-DZP 22.67149989 0.71195722 162650771 0.3P LDA-DZP 25.98480097 0.71195531 162650771 0.3P LDA-DZP 29.29810015 0.71195555 162650771 0.3P LDA-DZP 32.61140124 0.71195555 162650771 0.3P LDA-DZP 35.92469851 0.71195555 162650771 0.3P LDA-DZP 39.23799960 0.71195579 162650771 0.3P LDA-DZP 25.98480097 0.71195531 162650866 0.3Ni LDA-DZP 46.78737049 3.95633418 40807369 0.3Ni LDA-DZP 46.78737049 3.95633418 14.51182073 0.3Ni LDA-DZP 44.29552619 3.95633418 40807369 0.3Ni LDA-DZP 44.29552619 3.95633418 14.51182073 0.3Ni LDA-DZP 36.81999330 3.95633418 40807369 0.3Ni LDA-DZP 41.80368189 3.95633418 40807369 0.3Ni LDA-DZP 39.31183760 3.95633418 40807369 0.3Ni LDA-DZP 36.81999330 3.95633418 14.51182073 0.3Ni LDA-DZP 41.80368189 3.95633418 14.51182073 0.3Ni LDA-DZP 39.31183760 3.95633418 14.51182073 0.3Ni LDA-DZP 34.32814900 3.95633418 40807369 0.3Ni LDA-DZP 34.32814900 3.95633418 14.51182073 0.3Ni LDA-DZP 45.54144834 3.23700070 10.44265604 0.3Ni LDA-DZP 403329264 3.23700070 10.44265604 0.3Ni LDA-DZP 43.04960404 3.23700070 10.44265604 0.3Ni LDA-DZP 306591545 3.23700070 10.44265604 0.3Ni LDA-DZP 40.55775975 3.23700070 10.44265604 0.3Ni LDA-DZP 35.57407115 3.23700070 10.44265604 0.3Ni LDA-DZP 46.78737049 2.51766721 6.37349134 0.3Ni LDA-DZP 46.78737049 2.51766721 12.47723838 0.3Ni LDA-DZP 44.29552619 2.51766721 6.37349134 0.3Ni LDA-DZP 44.29552619 2.51766721 12.47723838 0.3Ni LDA-DZP 39.31183760 2.51766721 6.37349134 0.3Ni LDA-DZP 36.81999330 2.51766721 6.37349134 0.3Ni LDA-DZP 41.80368189 2.51766721 6.37349134 0.3Ni LDA-DZP 39.31183760 2.51766721 12.47723838 0.3Ni LDA-DZP 36.81999330 2.51766721 12.47723838 0.3Ni LDA-DZP 41.80368189 2.51766721 12.47723838 0.3Ni LDA-DZP 34.32814900 2.51766721 6.37349134 0.3Ni LDA-DZP 34.32814900 2.51766721 12.47723838 0.3Ni LDA-DZP 403329264 1.79833372 40807369 0.3Ni LDA-DZP 403329264 1.79833372 14.51182073 0.3Ni LDA-DZP 45.54144834 1.79833372 40807369 0.3Ni LDA-DZP 43.04960404 1.79833372 40807369 0.3Ni LDA-DZP 43.04960404 1.79833372 14.51182073 0.3Ni LDA-DZP 45.54144834 1.79833372 14.51182073 0.3Ni LDA-DZP 306591545 1.79833372 40807369 0.3Ni LDA-DZP 40.55775975 1.79833372 40807369 0.3Ni LDA-DZP 306591545 1.79833372 14.51182073 0.3Ni LDA-DZP 40.55775975 1.79833372 14.51182073 0.3Ni LDA-DZP 35.57407115 1.79833372 40807369 0.3Ni LDA-DZP 35.57407115 1.79833372 14.51182073 0.3Ni LDA-DZP 46.78737049 1.07900023 10.44265604 0.3Ni LDA-DZP 44.29552619 1.07900023 10.44265604 0.3Ni LDA-DZP 41.80368189 1.07900023 10.44265604 0.3Ni LDA-DZP 39.31183760 1.07900023 10.44265604 0.3Ni LDA-DZP 36.81999330 1.07900023 10.44265604 0.3Ni LDA-DZP 34.32814900 1.07900023 10.44265604 0.3Ni LDA-DZP 403329264 0.35966675 6.37349134 0.3Ni LDA-DZP 403329264 0.35966675 12.47723838 0.3Ni LDA-DZP 45.54144834 0.35966675 6.37349134 0.3Ni LDA-DZP 45.54144834 0.35966675 12.47723838 0.3Ni LDA-DZP 43.04960404 0.35966675 6.37349134 0.3Ni LDA-DZP 43.04960404 0.35966675 12.47723838 0.3Ni LDA-DZP 40.55775975 0.35966675 6.37349134 0.3Ni LDA-DZP 40.55775975 0.35966675 12.47723838 0.3Ni LDA-DZP 306591545 0.35966675 6.37349134 0.3Ni LDA-DZP 306591545 0.35966675 12.47723838 0.3Ni LDA-DZP 35.57407115 0.35966675 6.37349134 0.3Ni LDA-DZP 35.57407115 0.35966675 12.47723838 0.3Ni LDA-DZP 11.83630471 3.95633418 14.51182073 0.3Ni LDA-DZP 6.85261611 3.95633418 14.51182073 0.3Ni LDA-DZP 1.86892752 3.95633418 14.51182073 0.3Ni LDA-DZP 14.32814900 3.95633418 14.51182073 0.3Ni LDA-DZP 9.34446041 3.95633418 14.51182073 0.3Ni LDA-DZP 4.36077182 3.95633418 14.51182073 0.3Ni LDA-DZP 10.59038256 1.79833372 14.51182073 0.3Ni LDA-DZP 5.60669396 1.79833372 14.51182073 0.3Ni LDA-DZP 0.62300537 1.79833372 14.51182073 0.3Ni LDA-DZP 13.08222686 1.79833372 14.51182073 0.3Ni LDA-DZP 09853826 1.79833372 14.51182073 0.3Ni LDA-DZP 3.11484967 1.79833372 14.51182073 0.3Ni LDA-DZP 14.32814900 2.51766721 12.47723838 0.3Ni LDA-DZP 9.34446041 2.51766721 12.47723838 0.3Ni LDA-DZP 4.36077182 2.51766721 12.47723838 0.3Ni LDA-DZP 11.83630471 2.51766721 12.47723838 0.3Ni LDA-DZP 6.85261611 2.51766721 12.47723838 0.3Ni LDA-DZP 1.86892752 2.51766721 12.47723838 0.3Ni LDA-DZP 13.08222686 0.35966675 12.47723838 0.3Ni LDA-DZP 09853826 0.35966675 12.47723838 0.3Ni LDA-DZP 3.11484967 0.35966675 12.47723838 0.3Ni LDA-DZP 10.59038256 0.35966675 12.47723838 0.3Ni LDA-DZP 5.60669396 0.35966675 12.47723838 0.3Ni LDA-DZP 0.62300537 0.35966675 12.47723838 0.3Ni LDA-DZP 11.83630471 1.07900023 10.44265604 0.3Ni LDA-DZP 6.85261611 1.07900023 10.44265604 0.3Ni LDA-DZP 1.86892752 1.07900023 10.44265604 0.3Ni LDA-DZP 14.32814900 1.07900023 10.44265604 0.3Ni LDA-DZP 9.34446041 1.07900023 10.44265604 0.3Ni LDA-DZP 4.36077182 1.07900023 10.44265604 0.3Ni LDA-DZP 13.08222686 3.23700070 10.44265604 0.3Ni LDA-DZP 09853826 3.23700070 10.44265604 0.3Ni LDA-DZP 3.11484967 3.23700070 10.44265604 0.3Ni LDA-DZP 10.59038256 3.23700070 10.44265604 0.3Ni LDA-DZP 5.60669396 3.23700070 10.44265604 0.3Ni LDA-DZP 0.62300537 3.23700070 10.44265604 0.3Ni LDA-DZP 11.83630471 3.95633418 40807369 0.3Ni LDA-DZP 6.85261611 3.95633418 40807369 0.3Ni LDA-DZP 1.86892752 3.95633418 40807369 0.3Ni LDA-DZP 14.32814900 3.95633418 40807369 0.3Ni LDA-DZP 9.34446041 3.95633418 40807369 0.3Ni LDA-DZP 4.36077182 3.95633418 40807369 0.3Ni LDA-DZP 10.59038256 1.79833372 40807369 0.3Ni LDA-DZP 5.60669396 1.79833372 40807369 0.3Ni LDA-DZP 0.62300537 1.79833372 40807369 0.3Ni LDA-DZP 13.08222686 1.79833372 40807369 0.3Ni LDA-DZP 09853826 1.79833372 40807369 0.3Ni LDA-DZP 3.11484967 1.79833372 40807369 0.3Ni LDA-DZP 14.32814900 2.51766721 6.37349134 0.3Ni LDA-DZP 9.34446041 2.51766721 6.37349134 0.3Ni LDA-DZP 4.36077182 2.51766721 6.37349134 0.3Ni LDA-DZP 11.83630471 2.51766721 6.37349134 0.3Ni LDA-DZP 6.85261611 2.51766721 6.37349134 0.3Ni LDA-DZP 1.86892752 2.51766721 6.37349134 0.3Ni LDA-DZP 13.08222686 0.35966675 6.37349134 0.3Ni LDA-DZP 09853826 0.35966675 6.37349134 0.3Ni LDA-DZP 3.11484967 0.35966675 6.37349134 0.3Ni LDA-DZP 10.59038256 0.35966675 6.37349134 0.3Ni LDA-DZP 5.60669396 0.35966675 6.37349134 0.3Ni LDA-DZP 0.62300537 0.35966675 6.37349134 0.3end

(2)自洽计算:连接服务器(请参见Device Studio的工具栏中help→help Topic→7.应用实例→7.1Nanodcal实例)在选择服务器后,选中scf.input右击run。等待计算完毕后点击JobManager所示界面中的Action下的下载按钮下载NanodcalObject.mat文件。

以反平行结构Ni(111)/MBP/Ni(111)为例:

C.电极的自洽计算-APC

与平行结构所有的输入文件一致

D.中心区的自洽计算-APC

(1)准备输入文件:scf.input;基组文件Ni_LDA-DZP.nad,PNi_LDA-DZP.nad其中scf.input与平行结构的区别在于以下参数,其他参数一致。

%Description of electrodesystem.numberOfLeads = 2system.typeOfLead1 = frontsystem.voltageOfLead1 = 0system.objectOfLead1 = ../FrontElectrode/NanodcalObject.matsystem.spinDirectionOfLead1 = [0 0 1] %电极1的自旋方向system.typeOfLead2 = backsystem.voltageOfLead2 = 0system.objectOfLead2 = ../BackElectrode/NanodcalObject.matsystem.spinDirectionOfLead2 = [0 0 -1] %电极2的自旋方向

自洽计算后,我们就可以计算体系的各种物理性质。在本章中,我们将讲解如何计算分析电子透射谱、IV曲线、态密度、隧穿磁阻、自旋注入率。

1.3.2.2.2 非平衡态下的自洽计算

本节对Ni(111)/MBP/Ni(111)体系,进行了偏压0~100mV下的自洽计算。

(1)我们以偏压0.01V为例,准备输入文件 与本节前面平衡态下的自洽示例不同的是中心区自洽计算输入文scf.input:

system.voltageOfLead1 = 0.0 system.voltageOfLead2 = 0.0 变为 system.voltageOfLead1 = 0.005 system.voltageOfLead2 = -0.005 其他不变。

(2)自洽计算

(3)依次对偏压0.02V,0.03V,0.04V,0.05V,0.06V,0.07V,0.08V,0.09V,0.1V的体系进行自洽计算。

1.3.2.2.3 电子透射谱计算

对平衡态的体系进行电子透射谱计算。以平行结构为例:

(1)准备输入文件transmission.input,Simulator→Nanodcal→Analysis→Transmission→->→Generate file。

system.object = NanodcalObject.matcalculation.name = transmissioncalculation.transmission.kSpaceGridNumber = [ 300 1 1 ]'calculation.transmission.energyPoints = -5:0.025:5calculation.transmission.plot = truecalculation.control.xml = true

(2)自洽计算:连接服务器(请参见Device Studio的工具栏中help→help Topic→7.应用实例→7.1Nanodcal实例)在选择服务器后,选中scf.input右击run。等待计算完毕后点击JobManager所示界面中的Action下的下载按钮下载Transmission.mat、Transmission.xml、Transmission.fig、CalculatedResults.mat和log.txt文件。查看Transmission.mat文件可得出

>> load –mat Transmission.mat >> data.averagedTransmissionCoefficients ans = 0.0021 0.0111

对于反平行结构:计算的transmission.input和过程同平行结构 查看Transmission.mat文件可得出

>> load –mat Transmission.mat >> data.averagedTransmissionCoefficients ans = 0.0041 0.0041

说明:由于Ni(111)/MBP/Ni(111)结构具有对称性,所以反平行结构的自旋向上和向下的电子透射谱系数相同。

1.3.2.2.4 投影态密度计算

以平行结构Ni(111)/MBP/Ni(111)为例:对平衡态的体系进行态密度计算。

(1)准备输入文件densityOfStates.input,Simulator→Nanodcal→Analysis→DensityOfStates→->→Generate file。

(2)态密度计算(投影到原子):在Matlab界面,命令窗口输入:

system.object = NanodcalObject.matcalculation.name = densityOfStatescalculation.densityOfStates.kSpaceGridNumber = [ 8 1 1 ]'calculation.densityOfStates.numberOfEnergyPoints = 401calculation.densityOfStates.energyRange = [-3 , 3]calculation.densityOfStates.whatProjected = 'Atom'calculation.densityOfStates.plot = truecalculation.control.xml = true

(2)自洽计算:连接服务器(请参见Device Studio的工具栏中help→help Topic→7.应用实例→7.1Nanodcal实例)在选择服务器后,选中scf.input右击run。等待计算完毕后点击JobManager所示界面中的Action下的下载按钮下载DensityOfStates.mat、DensityOfStates.xml、DensityOfStates.fig和log.txt文件。

1.3.2.2.5 电流计算

对非平衡态的体系进行电流计算。我们以偏压0.01V为例:

(1)偏压Vbias被定义为VL-VR。对器件施加0.01 V偏压,中心区的输入文件scf.input改变如下,其他参数不变。

%Description of electrodesystem.numberOfLeads = 2system.typeOfLead1 = frontsystem.voltageOfLead1 = 0.005system.objectOfLead1 = ../FrontElectrode/NanodcalObject.matsystem.spinDirectionOfLead1 = [0 0 1] %电极1的自旋方向system.typeOfLead2 = backsystem.voltageOfLead2 = -0.005system.objectOfLead2 = ../BackElectrode/NanodcalObject.matsystem.spinDirectionOfLead2 = [0 0 -1] %电极2的自旋方向

-

(2)建立nanodcal计算IV曲线的输入文件,如下:

-

Simulator→Nanodcal→Analysis→IVcurve→->→Generate file。

参数默认,产生能带计算的输入文件IVcurve.input,同样,右击打开open with,可查看,如下:

calculation.name = ivccalculation.control.temporaryDirectory = ./calculation.IVCurve.systemObjectFiles = ../NanodcalObject.matcalculation.IVCurve.kSpaceGridNumber = [300 1 1]'calculation.control.xml = true

(3)IV曲线计算:与自洽计算步骤一样,选中IVcurve.input右击run。等待计算完毕后点击Job Manager所示界面中的Action下的下载按钮下载CurrentVoltageCurves.mat、CurrentVoltageCurves.fig、CurrentVoltageCurves.xml文件。

(4)查看数据,如下:

>> load –mat CurrentVoltageCurves.mat

>> data

V1: 0.0050

I1: 3.9405e-09 %电流值

I1_spinDecomposed: [2x1 double]

V2: -0.0050

I2: -3.9405e-09

I2_spinDecomposed: [2x1 double]

conductance: [1x1 struct]

description: [1x1040 char]

>> data.I1_spinDecomposed

ans =

1.0e-08 *

0.0814 %自旋向上的电流值

0.3126 %自旋向下的电流值

(5)依次对偏压0.02V,0.03V,0.04V,0.05V,0.06V,0.07V,0.08V,0.09V,0.1V的体系进行电流计算。

1.3.1.2.3 计算结果和分析

(1)作图和分析:I-V曲线和TMR、SIE (根据3.2.2 输运计算的结果,进行数据绘图)

I-V曲线 :

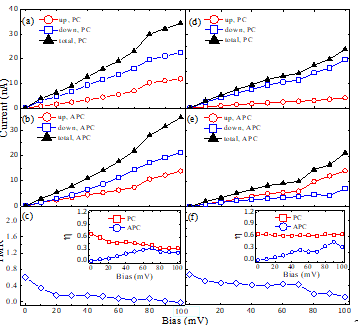

偏压0V,0.01V,0.02V,0.03V,0.04V,0.05V,0.06V,0.07V,0.08V,0.09V,0.1V的体系的电流数据依次取值,得到图1(a),(b),(d),(e)。其中 I_total=I_up+I_down 。

TMR和SIE曲线:

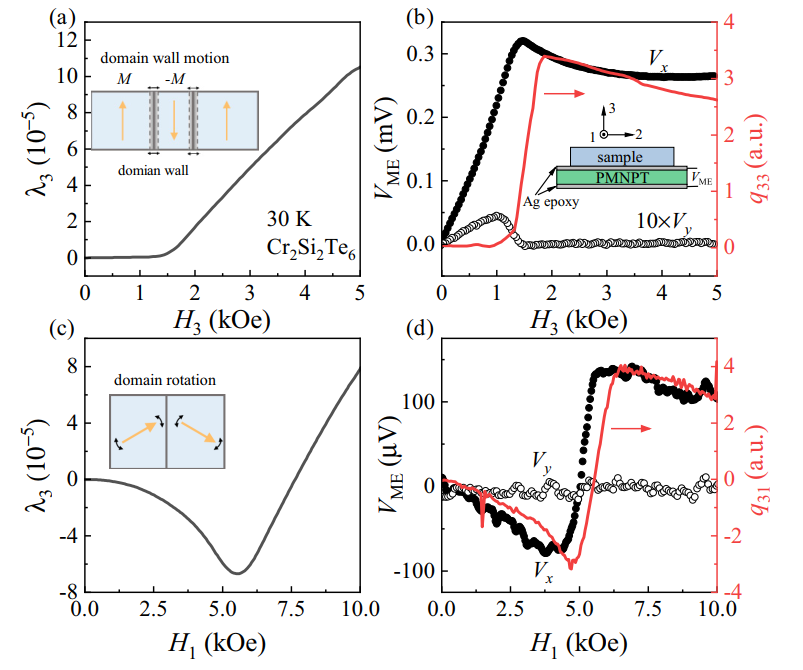

隧穿磁阻(Tunnel magnetoresistance),简称:TMR,我们将其定义为:TMR=(I_PC-I_APC)/I_APC ,其中I_PC、I_APC分别代表PC和APC结构的自旋极化电流;自旋极化率η=|(I_↑-I_↓)/(I_↑+I_↓ )|,I_↑和I_↓分别表示自旋向上和自旋向下的自旋极化电流。在平衡态时,即不加偏压时,TMR和η由费米能级处的电子透射谱系数计算得到。以上均适用于Ni(100)/MBP/Ni(100)体系。经过一系列计算和数据处理,得到如下图:

图 1-29:

图1-29 左侧图(a)、(b)、(c)分别代表 Ni(111MBP/Ni(111) MTJs PC结构的I-V曲线;APC结构的I-V曲线;随偏压变化的TMR和SIE(插图)。右侧图(d)、(e)、(f)分别代表 Ni(100)/MBP/Ni(100) MTJs PC结构的I-V曲线;APC结构的I-V曲线;随偏压变化的TMR和SIE(插图)。

注意:Ni(100)/MBP/Ni(100) MTJs具有持续稳定的TMR值

(2)结果分析:

对于Ni(111)/MBP/Ni(111) MTJs,电流沿着MBP的y (zigzag)方向;对于Ni(100)/MBP/Ni(100) MTJs,自旋电流沿着MBP的x (armchair)方向,见图1-1(e,f,g)所示。图1-2(a,b)和(d,e)分别给出了偏压0~100mV下Ni(111)/MBP/Ni(111)与Ni(100)/MBP/Ni(100)的自旋极化电流。对于Ni(111)和Ni(100)系统,在偏压0-70mV时,总电流I_(PC,APC)随着偏压线性增加;当偏压大于70mV时,随着偏压增加,I_(PC,APC)呈现非线性的快速增加。图2-2(a,b)表明Ni(111)系统的PC和APC结构的自旋极化电流I_↓总是大于I_↑。但对于Ni(100)系统,PC结构的自旋极化电流I_↓>I_↑,如图2-2(d);APC结构的自旋极化电流I_↓

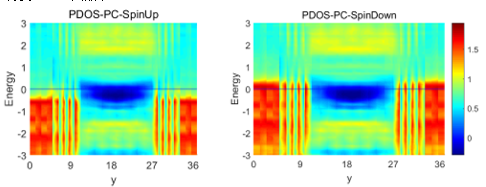

(1)作图和分析:PDOS

(根据3.2.2 输运计算中投影态密度的结果,进行数据绘图)得到PDOS图如下:

图 1-30:

图1-30 平衡态下:Ni(111)/MBP/Ni(111) MTJs平行结构的投影态密度(PDOS) 横坐标为输运方向y(Å),纵坐标为能量Energy(eV),右上方为竖直方向的条形颜色刻度,蓝色虚线为费米面。

(2)结果分析:

由图1-30知,在沿输运方向大约10Å至30Å的范围内,深蓝色区域为MBP的能隙禁区,表明此区域MBP形成输运势垒;从物理图像上看,左电极中自旋向上的电子为少数自旋态电子(态密度小),左电极中自旋向下的电子为多数自旋态电子(态密度大)。当镍电极的磁化方向平行时,即PC结构,则一个电极中多数自旋子带的电子将进入另一个电极中的多数自旋子带的空态,而少数自旋子带的电子也从这个电极进入另一个电极的少数自旋子带的空态。可以理解,当磁化取向平行排列时,电极中的多数自旋子带与一个高密度的空态相遇,故电阻低。磁化平行排列电阻小,形成低阻态;相反,磁化反平行排列电阻高,形成高阻态。总之,电子的输运一方面依赖于MBP势垒的隧穿过程,另一方面又与两端磁性金属的磁化相对取向有关。

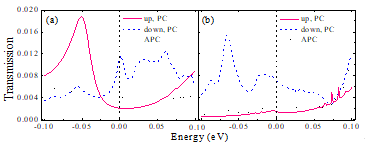

(1)作图和分析:某一能量范围下的电子透射谱(根据2.2.2 输运计算中电子透射谱的结果,进行提取数据并绘图)

图 1-31:

图1-31 平衡态下:PC和APC结构的电子透射谱,费米能级在0处 (a)为Ni(111)/MBP/Ni(111) MTJ;(b)为Ni(100)/MBP/Ni(100) MTJ

(2)结果分析:

为了进一步深入理解TMR和SIE,我们分析了平衡态下的电子透射谱。图1-31(a)和(b)分别为平衡态下,Ni(111)/MBP/Ni(111)及Ni(100)/MBP/Ni(100) MTJs的PC和APC结构的电子透射谱。由于这两个系统的结构具有对称性,因此APC结构的自旋向上和自旋向下的电子透射谱系数是相等的,所以在图1-31(a)和(b)中APC结构的电子透射谱系数只显示了一条曲线。对于PC结构,分别画出了自旋向上和自旋向下的电子透射谱系数。从图1-31中可看出,费米能级处的自旋向下的电子要比自旋向上的电子对透射谱系数贡献的多,从而导致平衡态下,两种系统具有相对较大的TMR和SIE值(PC结构), 如图1-31(c)和(f))。由于系统结构具有对称性,所以在平衡态下两个系统APC结构的SIE为0。图2-31的电子透射谱的分析方法与图1-31PDOS的分析方法基本一致, 如下:对于PC结构,MTJs的镍电极中自旋向下的电子态密度大,故自旋向下通道的电子透射谱系数大。对于APC结构,由于系统结构的对称性,MTJs的镍电极中自旋向上和自旋向下的电子态密度相同,故自旋向上和自旋向下通道的电子透射谱系数相等。

本章采用NEGF-DFT的计算方法,研究了镍/黑磷/镍隧道结的非平衡态的电输运性质。我们计算了外置偏压下的TMR、SIE、自旋极化电流、电荷电流、电子透射谱系数等。研究结果发现:(1) 在0~70mV偏压范围内,Ni(100)/MBP/Ni(100) MTJs具有稳定的高TMR和高SIE值,其中TMR≈40% 。对于PC结构,SIE≈60%。(2) Ni(100)/MBP/Ni(100)比Ni(111)/MBP/Ni(111)结构具有更好的自旋极化输运特性,这表明隧道结的界面结构对体系的TMR、SIE有重要影响。总之,Ni(100)/MBP/Ni(100) 比Ni(111)/MBP/Ni(111) 结构更适合应用于自旋电子器件。

审核编辑 :李倩

1.3.3 总结

-

电极

+关注

关注

5文章

830浏览量

27344 -

模拟器件

+关注

关注

2文章

107浏览量

23263

原文标题:产品教程|Nanodcal自旋器件(镍/黑磷/镍隧道结的电输运02)

文章出处:【微信号:hzwtech,微信公众号:鸿之微】欢迎添加关注!文章转载请注明出处。

发布评论请先 登录

相关推荐

STT-MRAM新型非易失性磁随机存储器

中国科大石墨烯量子点器件研究取得新突破

基于Rashba自旋轨道相互作用的非常规超导态和铁磁序

自旋忆阻器:最像大脑的存储器

自旋极化:开创半导体器件设计的新路径

ATA-2022B高压放大器在Lamb波中弹性波自旋调控研究中的应用

成像器件的工作原理是什么

TDK成功研发出用于神经形态设备的自旋忆阻器

互斥锁和自旋锁的实现原理

自旋锁和互斥锁的使用场景是什么

英特尔在可扩展硅基量子处理器领域取得重大突破

锁相放大器OE1022应用在二维铁磁自旋相关性的测量

通过TriVista高分辨率光谱测量系统测量量子材料的精细结构和自旋相互作用

Nanodcal自旋器件

Nanodcal自旋器件

评论