粉末电阻测试概述Overview of Powder Testing

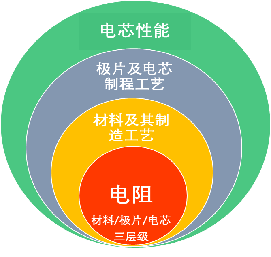

材料电阻直接影响着全电池功率表现。通过测量分析粉末、极片电阻等特性,在快速预测电池性能方面具有重要意义。 Resistivity of material directly affects the power performance of full battery. It is very important to predict the battery performance quickly by measuring and analyzing the characteristics of powder and electrode resistivity . 粉末导电材料的电阻率与材料本体电阻特性、粒度直接相关外,还与粉体堆积松紧度等直接关联。The resistivity of powder is not only directly related to the resistance characteristics and particle size of conductive material itself, but also directly related to the tightness of powder accumulation.

当前测量瓶颈Current situation and difficulties

粉末电阻的测试有多种方法,其中四探针是常用的方法之一。不过,四探针法仍存在如下问题亟需解决,以便方便高效地进行粉体电阻及压实密度的测试。Four probes is one of the commonly used methods for powder resistivity. However, the following problems need to be solved in order to facilitate and efficiently test powder resistance and press density.

非原位(需预压片,再转移至设备上测试),测试过程繁杂,影响因素众多;Ex-situ test(requires prepressing, then transferring it to the equipment for testing). The testing process is complicated and there are many influencing factors.

没有粉末电阻与压实密度一体设备;No powder resistivity and press density integrated equipment;

无法实现不同压力下粉末电阻与压实密度同步测试; The synchronous test of powder resistivity and press density under different pressures cannot be realized;

无法实现大压力下粉末电阻与压实密度测试 ;The test of powder resistivity and press density under high pressures cannot be realized.

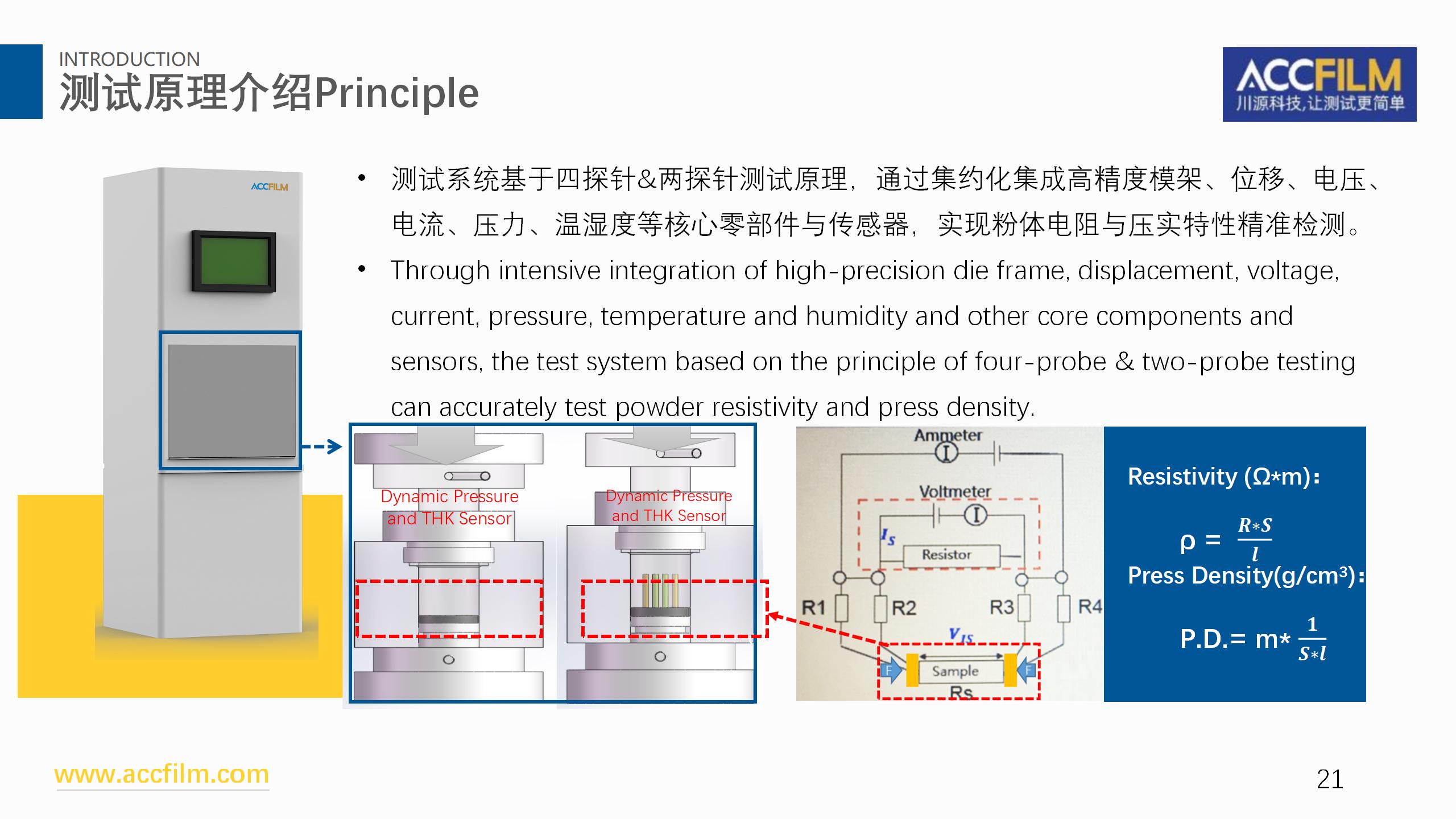

测试原理介绍Principle

测试系统基于四探针&两探针测试原理,通过集约化集成高精度模架、位移、电压、电流、压力、温湿度等核心零部件与传感器,实现粉体电阻与压实特性精准检测。

Through intensive integration of high-precision die frame, displacement, voltage, current, pressure, temperature and humidity and other core components and sensors, the test system based on the principle of four-probe & two-probe testing can accurately test powder resistivity and press density.

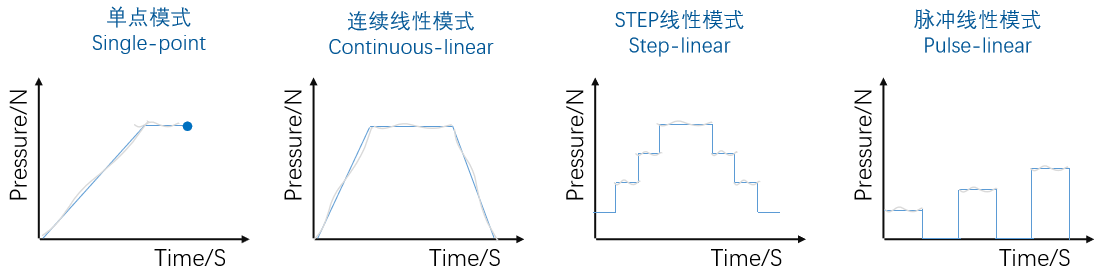

测量模式介绍Test Mode

测试系统实现以下功能 (类似电池充放电,CC+CV模式,Step Charge 模式); Test system realize the following function(similar to cell test, CC+CV mode,Step Charge mode):

不同加载压力速率到目标压力,目标压力保持一定时间, 直到电阻变化率小于0.01mΩ/s,完成测试;

For example :0.1t/s Constant Force rate(CFR) to 0.3t, Constant Force(CF) to 0.01mΩ/s, Frequency 0.2S。

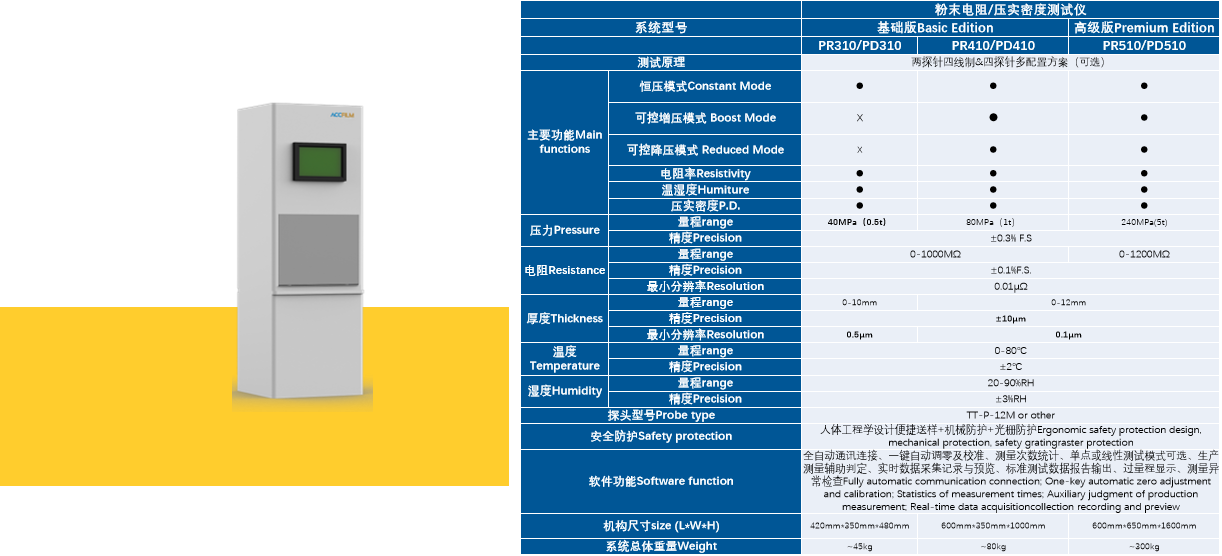

系统参数Specifications

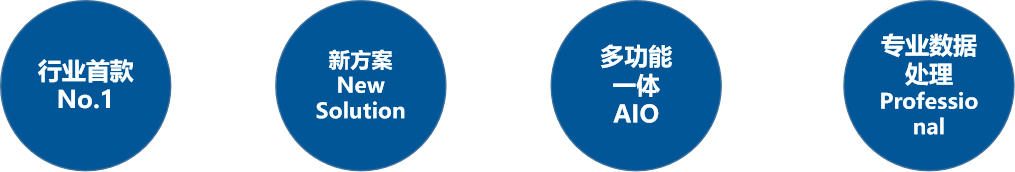

产品特色与优势Features and Advantages

可靠性分析Reliability Analysis

测试系统采用的是可控压力加压的测试来保证接触一致性,从而确保了测量的可靠性及稳定性,设备测试结果可靠,并且能达到量具R&R的标准要求。Test system adopt the controllable pressurize test to guarantee the contact uniformity, reliability and stability of test.

R&R可区分的类别数为9.35;The number of distinguishable R & R categories is 9.35;

方差分量贡献率及研究变异值大小同样显示系统的可靠性良好;%SV and 6*SD also display the better system reliability;

应用领域与方向Application Fields

ACCFILM膜片电阻测试系统应用于锂电池、超级电容器及镍氢电池等二次电池材料研发与生产相关领域的生产制造企业、大学及科研院所,其主要输出测量测试如下:

Manufacturing enterprises, universities and research institutes of lithium battery, supercapacitor and other secondary battery material related fields;

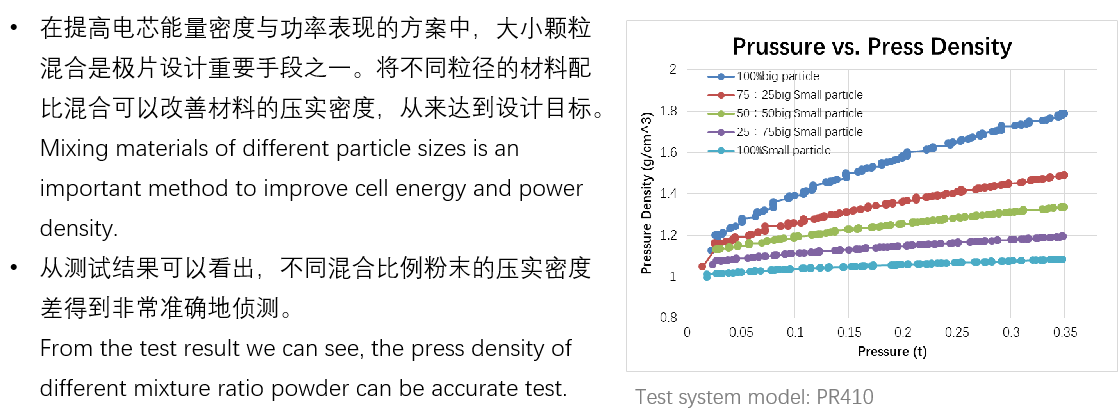

石墨混合压实密度分析Mixed Graphite Density Analyse

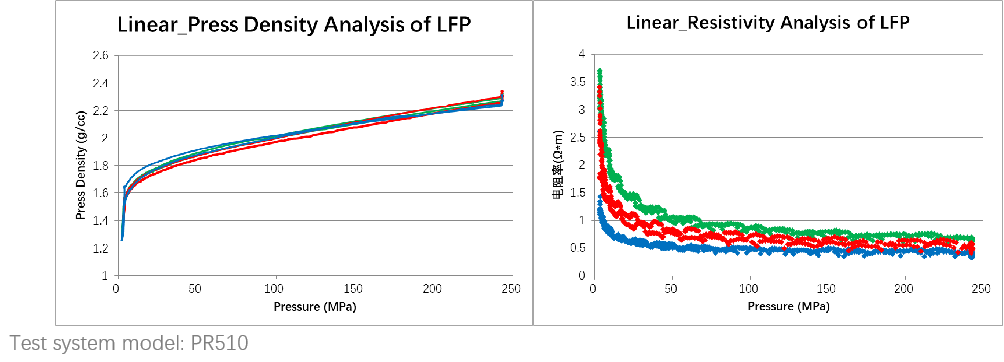

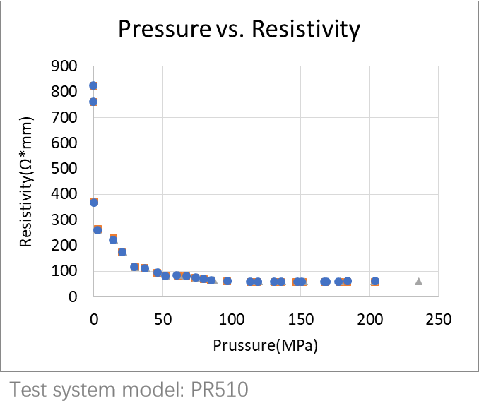

不同LFP材料测试分析Different LFP Material Analysis

为了研究更高压施压状态下粉体特性,以下为240MPa下三款LFP粉体的电导性及压实密度特性参数; To research powder characteristics under more higher pressure loading status, the below are resistivity and press density parameters of LFP powder under 240MPa; 三款材料中高能量型、能量型及倍率型的电阻率依次降低;The resistivity characteristics of three types materials match with the particle size design.

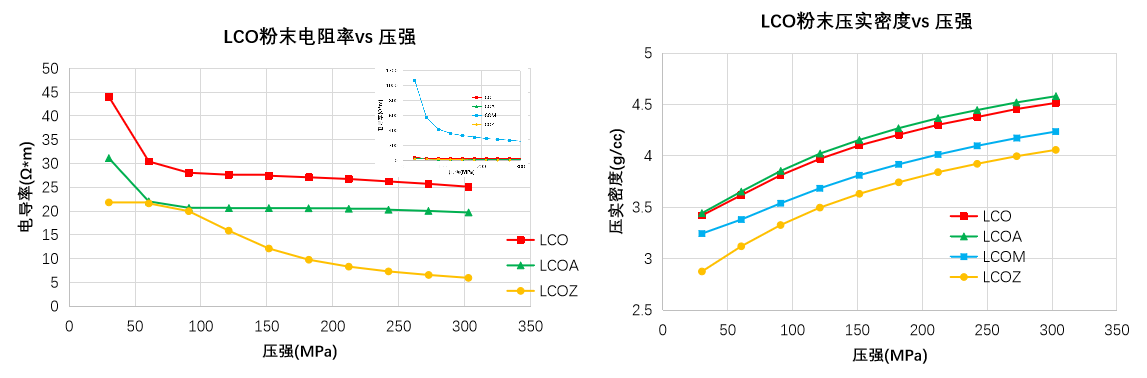

不同包覆改性LCO分析Doping LCO Analysis

300MPa下,LCOZ粉末电阻率最小5.946Ω*m,电阻从小到大依次为LCOZ<LCOA<LCO<LCOM,其中LCOM的组别实验组效果最差;

300MPa下,LCOA粉末压实密度最大达到4.58g/cc,压实密度从小到大依次为LCOZ<LCOM<LCO<LCOA;

压实密度和压力的关系趋势一致;

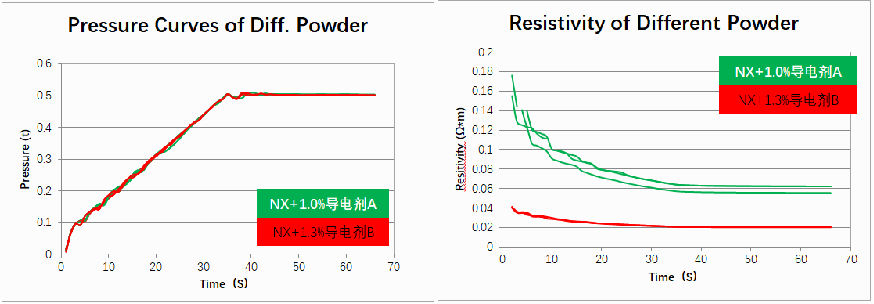

钠电池正极电阻分析 Na-ion Cell Cathode Materials Analyse

针对钠离子电池正极材料的材料导电性进行测试分析,以下为一款聚阴离子正极粉体(NX系列)混合两种不同导电添加剂的电导性评估. The below is the resistivity of polyanionic-based cathode materials (NX series) mixed two conductive additives:

NX+1.3%导电剂B的整体电导性比NX+1%导电剂A的效果好很多;The whole resistivity of NX+1.3%B more better than NX+1% A;

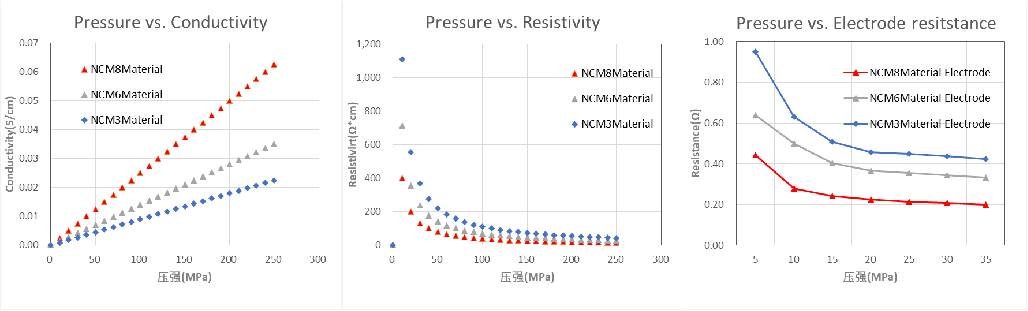

三元材料电阻率评估NCM Resistivity Analysis

针对不同三元材料的电导性测试应用,粉末电阻测试系统能有效地区分不同材料电阻率;Test system able to measure different type NCM material resistivity;

另外,可以看出粉末电阻率与极片电阻呈相同变化趋势。Additionally, we can see that resistivity and electrode resistance shows the same trend.

石墨粉料生产稳定性评估Stability of Graphite production

为了提高电池的一致性与可靠性,传统克容量、颗粒度、BET等检测已经不足以保证材料的一致性。所以,对于评价材料一致性非常有用的粉末电阻率就变得越来越重要。In order to improve the consistency and reliability of the battery, the traditional specific capacity, particle size, BET and other tests are not enough to ensure the consistency of the material. Therefore, powderresistivity test becomes more and more important.

右图展现了不同生产批次石墨粉料的电阻数据,用于材料生产稳定性监控。 The picture show the resistivity data of different graphite batches, which is used to monitor the stability of material production.

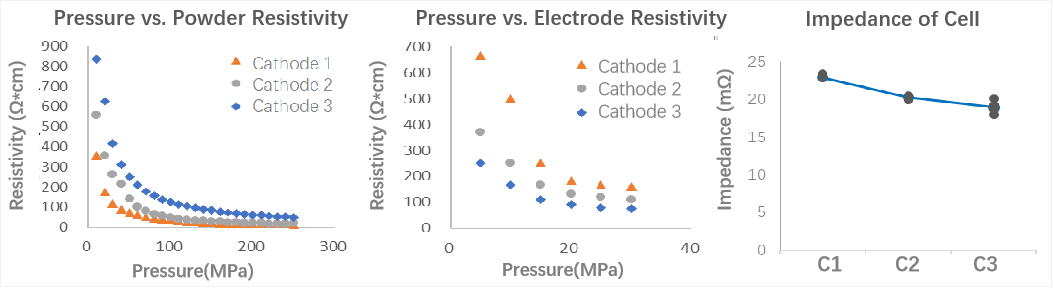

粉末、极片与电芯电阻关联分析Correlation analysis of powder, electrode and Cell

为了加快电池研发效率,希望通过零部件的性能来预测电芯性能,比如:利用粉末电阻、极片电阻来预测电芯内阻、功率等表现;By analyzing the resistance components of different levels(Such as powder, electrode ) to predict the performance of full cell.

以下示例为NCM811材料在不同导电添加剂量下粉末、极片及电芯内阻的对应结果。The corresponding results of powder, electrode and cell resistance of NCM811 with different conductive additive.

审核编辑黄宇

-

电阻

+关注

关注

86文章

5575浏览量

173231 -

测试

+关注

关注

8文章

5460浏览量

127390 -

电池

+关注

关注

84文章

10756浏览量

132124

发布评论请先 登录

相关推荐

IGBT饱和压降Vsat实测值和官方参数对比

【QR-10系列通用型袖珍可编程电阻箱试用体验】---之电阻数据实测

Maxim推出坚固耐用的/PR系列塑封器件,适合军用和航空设

Vishay发布ORNV系列模压双列直插电阻分压器

什么是电阻分压?电阻分压的工作原理是什么?电阻分压和限流是一个概念吗?

接地电阻测试记录表_接地电阻测试记录_万用表怎么测接地电阻

粉末电阻/压实测试(PR系列)

粉末电阻/压实测试(PR系列)

评论