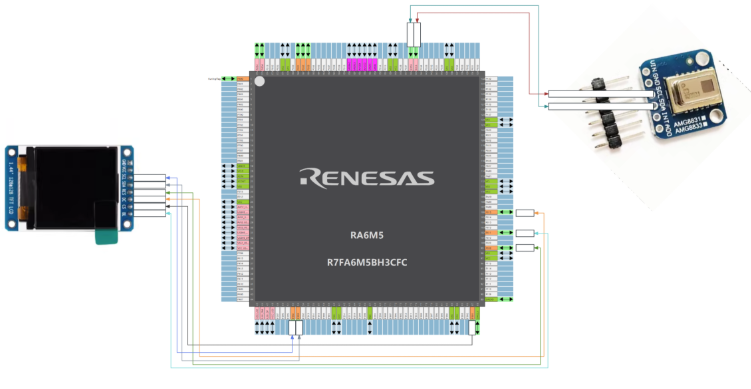

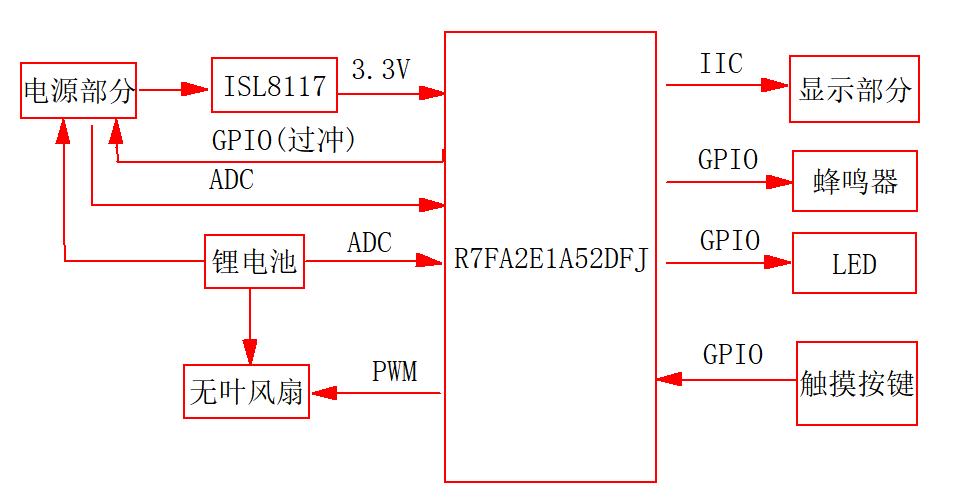

本项目主要以启明6M5开发板作为主控,通过AMG8833模块获取手部的温度,然后通过BP神经网络解析温度数据,来识别手部动作。当手部动作和预定控制指令激活动作相匹配时,向外部设备发送控制指令,当外部设备接收到对应指令执行对应的操作。

因为该设备是通过手部温度作为控制变量,所以项目运行的温度在28℃摄氏度下(设备静态是经过传感器测量得到的数据)。手部温度为33℃左右,手部距离传感器大概在5cm左右,并且处于传感器芯片正前方。说明:环境温度会影响传感器的识别。

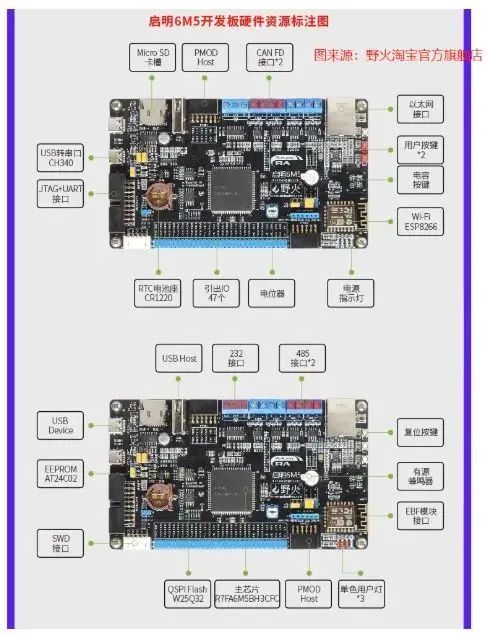

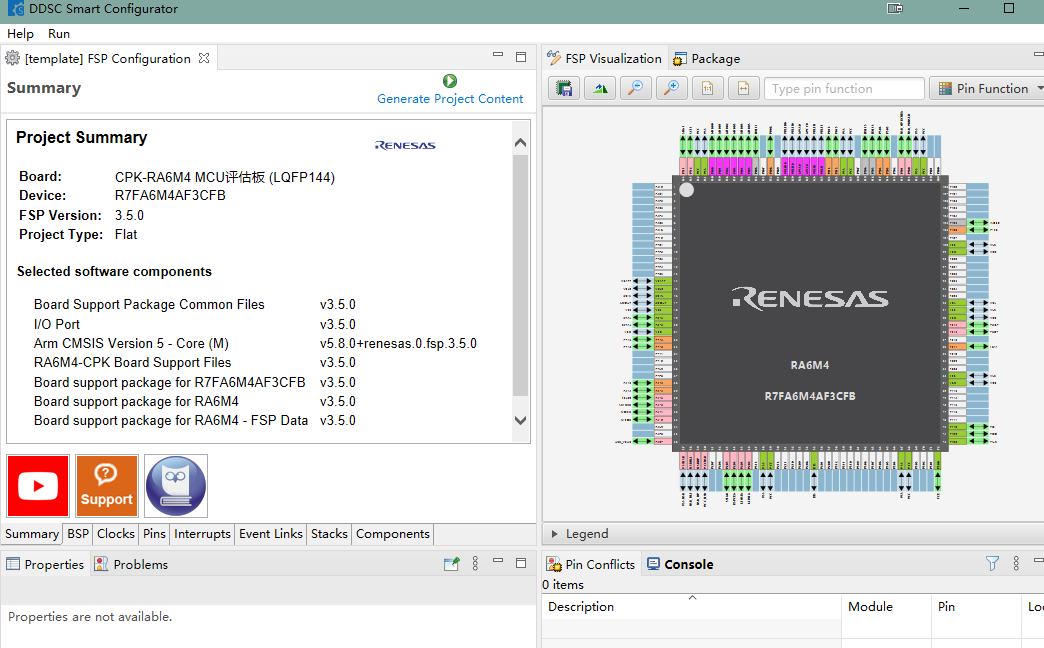

硬件部分

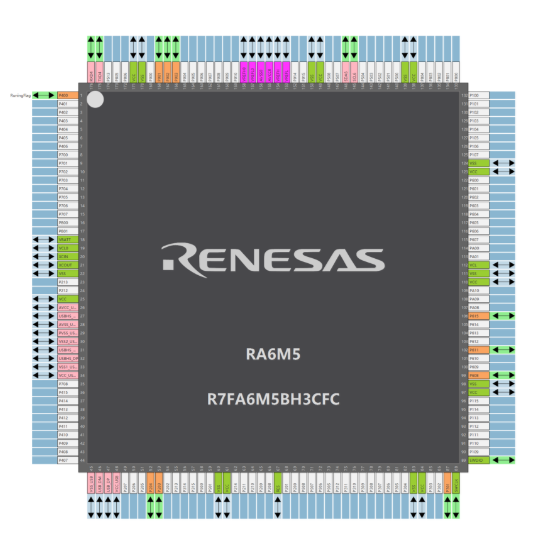

①设备型号

野火RA6M5开发

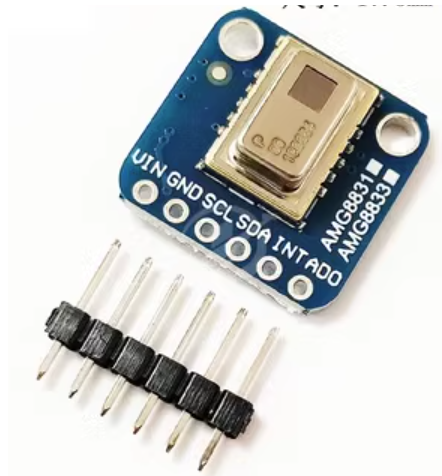

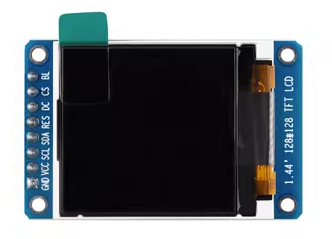

②外围设备

GY- AMG8833 IR 8x8 红外热像

1.44寸彩色TFT显示屏高清IPS LCD液晶屏模块128*128

③其他配件

面包板 x 1杜邦线若干

④设备引脚配置

⑤引脚连接

以及串口:

TX : P512

RX: P511

软件部分

项目完成使用到的软件有:

e2 studio

vs code

字模软件 PCtoLCD2013

野火串口调试助手

软件部分代码说明:

1、GY- AMG8833 IR 8x8 红外热像仪 驱动部分代码说明:

AMG8833模块使用I2C 通讯协议:(使用硬件I2C)

下面是模块是主要的各个功能驱动函数

根据数据手册说明:只要主机向从机发送0x80指令,从机设备 会直接 一次性按顺序发送完 温度栅格点 1-64 的温度数据

其他指令:按照I2C 通讯协议读取

I2C 驱动 .C 文件部分函数

// 设置传感器模式

void AMG88_SetSensorMode(AMG88_OperatingMode Mode)

{

unsigned char buffer[2]={0x00,Mode};

R_SCI_I2C_Write(&g_i2c6_ctrl, buffer, 2, false);

return;

}

// 获取当前传感器模式

unsigned char AMG88_GetSensorMode(void)

{

unsigned char OperatingModeBuffer=0;

R_SCI_I2C_Write(&g_i2c6_ctrl, 0, 1, true);

R_BSP_SoftwareDelay(2, 1000);

//Read Register data

R_SCI_I2C_Read(&g_i2c6_ctrl, &OperatingModeBuffer, 1, false);

return OperatingModeBuffer;

}

// 重启传感器

void AMG88_SensorReset(AMG88_ResetMode Mode)

{

//

unsigned char ResetBuffer[2]={0x01,(unsigned char)Mode};

//unsigned char ResetBuffer=0x30;

R_SCI_I2C_Write(&g_i2c6_ctrl, ResetBuffer, 2, false);

return;

}

// 设置帧率

void AMG88_SetFrameRate(AMG88_Frame Frame)

{

unsigned char ResetBuffer[2]={0x02,(unsigned char)Frame};

//unsigned char ResetBuffer=0x30;

R_SCI_I2C_Write(&g_i2c6_ctrl, ResetBuffer, 2, false);

return;

}

// 获取传感器帧率

unsigned char AMG88_GetFrameRate(void)

{

unsigned char OperatingModeBuffer=0;

unsigned char Address[1]={0x02};

R_SCI_I2C_Write(&g_i2c6_ctrl, Address, 1, true);

R_BSP_SoftwareDelay(2, 1000);

//Read Register data

R_SCI_I2C_Read(&g_i2c6_ctrl, &OperatingModeBuffer, 1, false);

R_BSP_SoftwareDelay(2, 1000);

return OperatingModeBuffer;

}

// 设置中断控制寄存器

void AMG88_SetICR(AMG88_ICR_REGISTER ICR)

{

unsigned char ResetBuffer[2]={0x03,(unsigned char)ICR};

//unsigned char ResetBuffer=0x30;

R_SCI_I2C_Write(&g_i2c6_ctrl, ResetBuffer, 2, false);

return;

}

// 获取中断控制寄存器的数据

unsigned char AMG88_GetICR(void)

{

unsigned char OperatingModeBuffer=0;

unsigned char Address[1]={0x03};

R_SCI_I2C_Write(&g_i2c6_ctrl, Address, 1, true);

// R_SCI_I2C_Write(&g_i2c6_ctrl, 0x03, 1, true);

R_BSP_SoftwareDelay(2, 1000);

//Read Register data

R_SCI_I2C_Read(&g_i2c6_ctrl, &OperatingModeBuffer, 1, false);

return OperatingModeBuffer;

}

// 获取当前传感器状态

unsigned char AMG88_GetStatus(void)

{

unsigned char OperatingModeBuffer=0;

unsigned char Address[1]={0x04};

R_SCI_I2C_Write(&g_i2c6_ctrl, Address, 1, true);

// R_SCI_I2C_Write(&g_i2c6_ctrl, 0x04, 1, true);

R_BSP_SoftwareDelay(2, 1000);

//Read Register data

R_SCI_I2C_Read(&g_i2c6_ctrl, &OperatingModeBuffer, 1, false);

return OperatingModeBuffer;

}

// 清除传感器标志位

void AMG88_SetStatusClear(AMG_Status_FLAG ClearStatus)

{

unsigned char ResetBuffer[2]={0x05,(unsigned char)ClearStatus};

//unsigned char ResetBuffer=0x30;

R_SCI_I2C_Write(&g_i2c6_ctrl, ResetBuffer, 2, false);

return;

}

//

void AMG88_SetAverage(BOOL Flag)

{

unsigned char ResetBuffer[2]={0x07,(Flag==TRUE)?(0xFF):(0)};

//unsigned char ResetBuffer=0x30;

R_SCI_I2C_Write(&g_i2c6_ctrl, ResetBuffer, 2, false);

}

//

unsigned char AMG88_GetAverage(void)

{

unsigned char OperatingModeBuffer=0;

// R_SCI_I2C_Write(&g_i2c6_ctrl, 0x07, 1, true);

unsigned char Address[1]={0x07};

R_SCI_I2C_Write(&g_i2c6_ctrl, Address, 1, true);

R_BSP_SoftwareDelay(2, 1000);

//Read Register data

R_SCI_I2C_Read(&g_i2c6_ctrl, &OperatingModeBuffer, 1, false);

return OperatingModeBuffer;

}

// 设置中断优先级

void AMG88_SetILR(unsigned char *ValueBuffer,unsigned char ArrayLenth)

{

unsigned char ResetBuffer[7]={0x08,0x00,0x00,0x00,

0x00,0x00,0x00};

if(ArrayLenth<=7 && ArrayLenth >= 1)

return;

for(unsigned char i= 1 ;i<7;i++)

{

if(i%2==0)

{

ResetBuffer[i]=(0x0F & ValueBuffer[i-1]);

}else

{

ResetBuffer[i]=ValueBuffer[i-1];

}

}

//unsigned char ResetBuffer=0x30;

R_SCI_I2C_Write(&g_i2c6_ctrl, ResetBuffer, ArrayLenth+1, false);

return;

}

unsigned char Tempeture_Flag[2];

// 获取传感器 热敏电阻 电阻值

unsigned short AMG88_GetThermistor(void)

{

unsigned short buffer_flag=0;

unsigned char Address[1]={0x0E};

R_SCI_I2C_Write(&g_i2c6_ctrl, Address, 1, true);

// R_SCI_I2C_Write(&g_i2c6_ctrl, 0x0E, 1, true);

R_BSP_SoftwareDelay(2, 1000);

//Read Register data

R_SCI_I2C_Read(&g_i2c6_ctrl, &Tempeture_Flag[0], 1, false);

R_BSP_SoftwareDelay(2, 1000);

Address[0]=0x0F;

R_SCI_I2C_Write(&g_i2c6_ctrl, Address, 1, true);

R_BSP_SoftwareDelay(2, 1000);

R_SCI_I2C_Read(&g_i2c6_ctrl, &Tempeture_Flag[1], 1, false);

R_BSP_SoftwareDelay(2, 1000);

buffer_flag=Tempeture_Flag[1]<<8;

buffer_flag|=Tempeture_Flag[0];

return buffer_flag;

}

unsigned char Buffer[10];

unsigned char Revice[128];

// 获取传感器的温度

void AMG88_SensorData(void)

{

/*

* register address

*

* */

Buffer[0]=0x80;

//Send slave address

R_SCI_I2C_Write(&g_i2c6_ctrl, Buffer, 1, true);

R_BSP_SoftwareDelay(2, 1000);

//Read Register data

R_SCI_I2C_Read(&g_i2c6_ctrl, Revice, 128, false);

}

2、1.44寸彩色TFT显示屏高清IPS LCD液晶屏模块128*128 部分代码说明

该LCD 液晶屏使用SPI 通讯协议:(使用模拟SPI)

驱动芯片为ST7735SPI

驱动 .C 文件部分函数

void SPI_init(void)

{

SET_LED();

SET_CS();

SET_CDX();

SET_RST();

SET_CLK();

SET_SDA();

return;

}

void SPI_SendData(unsigned char Data) // CDX = 1

{

unsigned char i;

for (i = 0; i < 8; i++)

{

CLEAR_CLK();

if ((Data & 0x80) != 0)

SET_SDA();

else

CLEAR_SDA();

Data <<= 1;

SET_CLK();

}

return;

}

void SPI_WriteCommand(unsigned char Data) //CDX = 0

{

CLEAR_CS();

CLEAR_CDX();

SPI_SendData (Data);

SET_CS();

return;

}

void SPI_WriteData(unsigned char Data) //CDX = 1

{

CLEAR_CS();

SET_CDX();

SPI_SendData (Data);

SET_CS();

return;

}

void WriteDispData(unsigned char DataH, unsigned char DataL)

{

SPI_SendData (DataH);

SPI_SendData (DataL);

}

void LCD_Init(void)

{

SET_RST();

R_BSP_SoftwareDelay (100, BSP_DELAY_UNITS_MILLISECONDS);

CLEAR_RST();

R_BSP_SoftwareDelay (100, BSP_DELAY_UNITS_MILLISECONDS);

SET_RST();

R_BSP_SoftwareDelay (200, BSP_DELAY_UNITS_MILLISECONDS);

SPI_WriteCommand (0x11); //Exit Sleep

R_BSP_SoftwareDelay (120, BSP_DELAY_UNITS_MILLISECONDS);

SPI_WriteCommand (0xB1);

SPI_WriteData (0x05); //0a

SPI_WriteData (0x3c); //14

SPI_WriteData (0x3c);

SPI_WriteCommand (0xB2);

SPI_WriteData (0x05);

SPI_WriteData (0x3c);

SPI_WriteData (0x3c);

SPI_WriteData (0xB3);

SPI_WriteData (0x05);

SPI_WriteData (0x3c);

SPI_WriteData (0x3c);

SPI_WriteData (0x05);

SPI_WriteData (0x3c);

SPI_WriteData (0x3c);

SPI_WriteCommand (0xB4); // 前面的b1-b5 是设置帧速率

SPI_WriteData (0x03);

SPI_WriteCommand (0xC0); // Set VRH1[4:0] & VC[2:0] for VCI1 & GVDD Power Control

SPI_WriteData (0x28);

SPI_WriteData (0x08);

SPI_WriteData (0x04);

SPI_WriteCommand (0xC1); // Set BT[2:0] for AVDD & VCL & VGH & VGL

SPI_WriteData (0xC0);

SPI_WriteCommand (0xC2); // Set VMH[6:0] & VML[6:0] for VOMH & VCOML

SPI_WriteData (0x0D); //54h

SPI_WriteData (0x00); //33h

SPI_WriteCommand (0xC3);

SPI_WriteData (0x8D);

SPI_WriteData (0x2A);

SPI_WriteCommand (0xC4);

SPI_WriteData (0x8D);

SPI_WriteData (0xEE);

SPI_WriteCommand (0xC5);

SPI_WriteData (0x1A);

SPI_WriteCommand (0x36); //MX,MY,RGB MODE

SPI_WriteData (0x08);

SPI_WriteCommand (0xe0);

SPI_WriteData (0x04); //2c

SPI_WriteData (0x22);

SPI_WriteData (0x07);

SPI_WriteData (0x0A);

SPI_WriteData (0x2E);

SPI_WriteData (0x30);

SPI_WriteData (0x25);

SPI_WriteData (0x2A);

SPI_WriteData (0x28);

SPI_WriteData (0x26);

SPI_WriteData (0x2E);

SPI_WriteData (0x3A);

SPI_WriteData (0x00);

SPI_WriteData (0x01);

SPI_WriteData (0x03);

SPI_WriteData (0x03);

SPI_WriteCommand (0xe1);

SPI_WriteData (0x04);

SPI_WriteData (0x16);

SPI_WriteData (0x06);

SPI_WriteData (0x06);

SPI_WriteData (0x0D);

SPI_WriteData (0x2D);

SPI_WriteData (0x26);

SPI_WriteData (0x23);

SPI_WriteData (0x27);

SPI_WriteData (0x27);

SPI_WriteData (0x25);

SPI_WriteData (0x2D);

SPI_WriteData (0x3B);

SPI_WriteData (0x00);

SPI_WriteData (0x01);

SPI_WriteData (0x04);

SPI_WriteData (0x13);

SPI_WriteCommand (0x3A);

SPI_WriteData (0x05);

SPI_WriteCommand (0x29); // Display On

R_BSP_SoftwareDelay (20, BSP_DELAY_UNITS_MILLISECONDS);

}

void BlockWrite(unsigned short Xstart, unsigned short Xend, unsigned short Ystart, unsigned short Yend)

{

SPI_WriteCommand (0x2A);

SPI_WriteData (Xstart >> 8);

SPI_WriteData (Xstart + 2);

// SPI_WriteData(Xstart);

SPI_WriteData (Xend >> 8);

SPI_WriteData (Xend + 2);

// SPI_WriteData(Xstart);

SPI_WriteCommand (0x2B);

SPI_WriteData (Ystart >> 8);

SPI_WriteData (Ystart + 1);

SPI_WriteData (Yend >> 8);

SPI_WriteData (Yend + 1);

SPI_WriteCommand (0x2c);

}

void DispColor(unsigned short color)

{

unsigned short i, j;

BlockWrite (0, COL - 1, 0, ROW - 1);

for (i = 0; i < ROW; i++)

{

for (j = 0; j < COL; j++)

{

SPI_WriteData (color >> 8);

SPI_WriteData (color);

// DelayMs(1);

}

}

}

void ClearFullScreen(void)

{

unsigned short i, j;

BlockWrite (0, COL - 1, 0, ROW - 1);

for (j = 0; j < COL; j++)

{

SPI_WriteData (i + 50);

SPI_WriteData (j + 50);

}

return;

}

void DrawColor(unsigned short ColorNumber)

{

SPI_WriteData (0xFF);

SPI_WriteData (0xFF);

return;

}

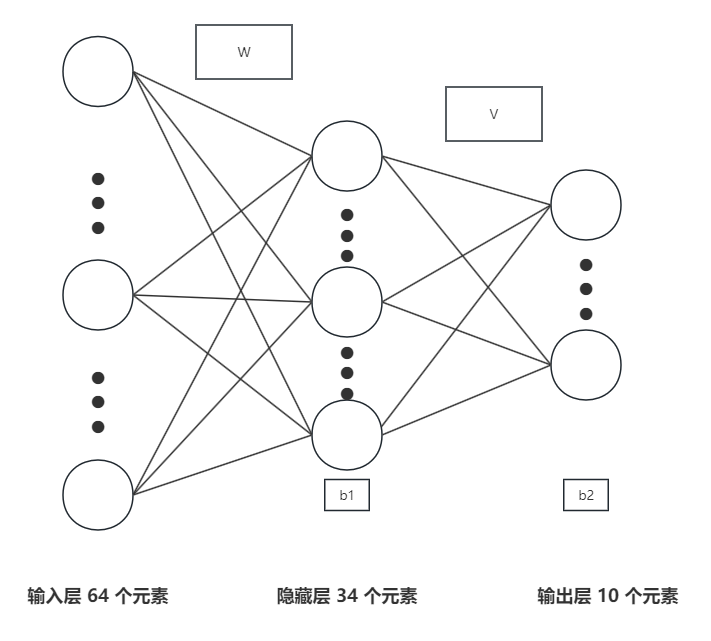

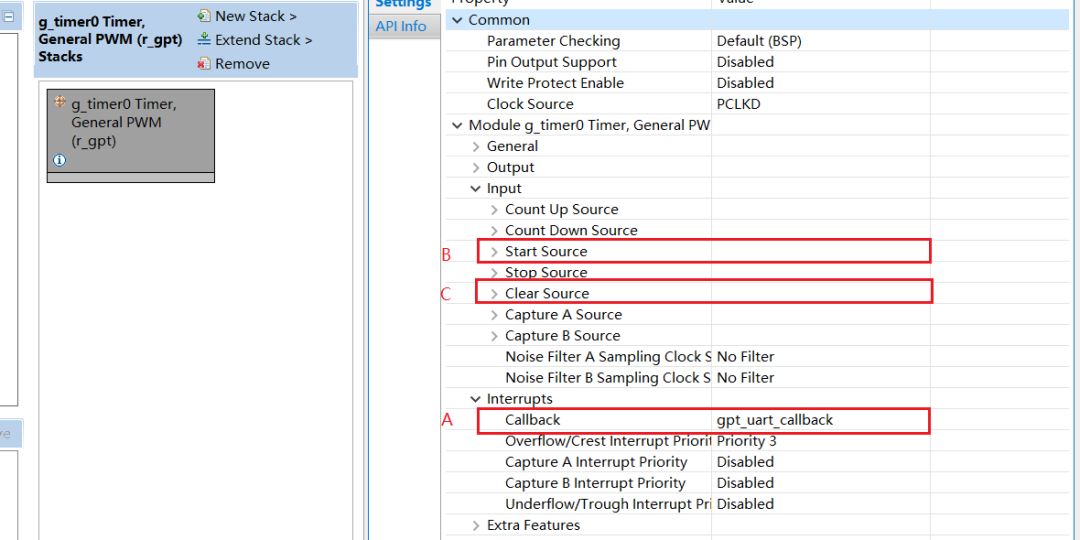

3、BP 神经网络:

代码说明:

三层网络结构:

第一层是输入层,第二层是隐藏层,第三层是输出层

神经网络预测代码说明:

神经网络预测的原理是,将目标数据输入到神经网络中,经过神经网络中参数的迭代,使之得到符合要求的数据数据,然后保存神经网络中的参数(各个节点的权重参数)。使用该网络预测时,将训练好的参数,导入到神经网络中,该神经网络就预测和神经网络中相符合的数据。

该神经网络的相关信息如下:

三层BP神经网络:

输入层有64个元素 , 隐藏层有34个元素, 输出层有10个元素

训练次数为:10000次,最终的错误率为:0.00658,学习率为:0.1 ,动量因子:0.1 训练数据总共160组 (160组中 ,分成三份)总共训练了三个手势

手势1 36组数据 手势2 68组数据 手势3 54组数据 上图:为编写文档时所拍,非传感器测量时图片,仅说明在采集测试数据时的手势动作

训练数据示例:

[[0.0000,0.0000,0.0000,0.0000,0.5,0.0000,0.0000,0.5,0.0000,0.0000,0.0000,0.5,0.5,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.5,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.5,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.5,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.5,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000],[0,1,0,0,0,0,0,0,0,0]],

// 手势 1 要求输出 结果 -----> [0,1,0,0,0,0,0,0,0,0]

[[0.0000,0.0000,0.5,0.5,0.0000,0.5,0.5,0.5,0.0000,0.0000,0.5,0.0000,0.0000,0.5,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.5,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.5,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.5,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.5,0.5,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000],[0,0,1,0,0,0,0,0,0,0]],

// 手势 2 要求输出 结果 -----> [0,0,1,0,0,0,0,0,0,0]

[[0.0000,0.0000,0.0000,0.5,0.5,0.5,0.5,0.5,0.0000,0.0000,0.0000,0.5,0.5,0.5,0.0000,0.5,0.0000,0.0000,0.5,0.0000,0.0000,0.5,0.0000,0.5,0.0000,0.5,0.0000,0.0000,0.0000,0.5,0.0000,0.0000,0.0000,0.5,0.0000,0.0000,0.0000,0.0000,0.0000,0.5,0.0000,0.0000,0.0000,0.0000,0.5,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.5,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000,0.0000],[0,0,0,1,0,0,0,0,0,0]]

// 手势 3 要求输出 结果 -----> [0,0,0,1,0,0,0,0,0,0]

// 注:以上数据仅为 测试数据中的手势数据的 一部分 ,不代表整体数据

// 预测输出数据 示例:

[-0.0023248156377385144, 0.035785164105157696, 0.05889932014156386, 0.9992514065884543, 0.0003713636538696458, -0.002541229896438062, -0.0033772818188316607, -0.0023972941452978813, 0.001043452650557289, -0.0026320033807735485]

输出数据说明:

该网络有10个数据输出 ,(如:[0,0,0,1,0,0,0,0,0,0] (从左往右)依次是 0 - 9 手势 ,但本次训练 仅仅训练了3个手势, 结果如上。

其他信息说明:

本次的隐藏层的数目依次经历了 12->24->128->34 的变化 ,具体的数目和输入输出的元素个数,没有实际的关联(网上虽然有建议) ,具体看情况而论,因为是三层网络,隐藏层的数量不可以太少,也不可以太多,太少,说简单的,输出的数据不在[0,1]的区间,太多,输出的都是0.9左右的数据

输出的数据不在[0,1]的区间

可以调整 学习率 或者 训练次数(增加),或者是动量因子(修改该参数时,学习率不变)

调整隐藏层的节点数目(往大了调)

输出的都是0.9左右的数据(过拟合)

调整隐藏层的节点数目(往小了调)(按实际情况调节)

输出数据的设定,按照激活函数的取值选择

输入数据的选择,[0-1]之间 ,为了提供训练的成功率,在输入数据中做了一些处理

训练的前提是保证网络正常(代码没有写错)

优化训练的操作说明:

对数据进行了非0即0.5 的处理 ,对于超过 特定温度值的数据为0.5 ,不超过为 0(只要有相对应的特征即可)

网络训练成功的标志,输出的数据在(本网络)[0,1]之间,并且输出的数据 对应符合 输入的数据(只要有符合的即可尝试在在设备上运行),建议训练完成的网络,在预测时,要同时多预测几个,防止是误差

// 激活函数

double sigmoid(double x)

{

return tanh(x);

}

// 前向传播

void Forward()

{

unsigned char i=0,j=0;

double Temp=0.0;

double *InputValueTemp;

InputValueTemp=InputValue;

for( i=0 ;i< HIDDENSIZE ; i++)

{

Temp=0;

for(j=0 ; j < INPUTSIZE ; j++ )

{

Temp+=InputValue[j]*InputWeight[j*HIDDENSIZE+i];

}

HiddenValue[i]=sigmoid(Temp);

}

for( i=0 ;i < OUTPUTSIZE ; i++)

{

Temp=0;

for( j = 0; j < HIDDENSIZE ;j++ )

{

Temp+=HiddenValue[j]*OutputWeight[j*OUTPUTSIZE+i];

}

OutputValue[i]=sigmoid(Temp);

}

}

}

左上角

手势1 白色

手势2 浅绿色

手势3 浅紫色

本项目还有需要优化的地方,也有着许多不足。作者水平有限,希望广大网友批评指正。

审核编辑:汤梓红

-

传感器

+关注

关注

2552文章

51246浏览量

754846 -

mcu

+关注

关注

146文章

17186浏览量

351760 -

神经网络

+关注

关注

42文章

4775浏览量

100912 -

瑞萨

+关注

关注

35文章

22309浏览量

86465

原文标题:【瑞萨RA MCU创意氛围赛作品赏析】项目14——手势识别控制终端

文章出处:【微信号:瑞萨MCU小百科,微信公众号:瑞萨MCU小百科】欢迎添加关注!文章转载请注明出处。

发布评论请先 登录

相关推荐

基于瑞萨RA MCU的手势识别控制终端设备设计

基于瑞萨RA MCU的手势识别控制终端设备设计

评论