硅外延层和衬底是半导体制造过程中的两个重要组成部分。衬底是半导体芯片制造的基础,主要由单晶硅材料制成。硅外延层是在衬底上加工生长的一层硅材料,其材料特性与衬底相同。二者在成份、结构和性质上都有所不同。

Silicon epitaxial layers and substrates are two important components in the semiconductor manufacturing process. The substrate is the basis for semiconductor chip manufacturing and is mainly made of single crystal silicon material. The silicon epitaxial layer is a layer of silicon material processed and grown on the substrate, and its material properties are the same as the substrate. Both are different in composition, structure and properties.

衬底 Substrate 衬底,作为半导体单晶材料制成的晶圆片,它既可以直接进入晶圆制造流程,用于生产半导体器件;也可通过外延工艺加工,产出外延片。半导体衬底就像一块“地基”,它支撑着整个半导体结构,确保它不会破裂或损坏。同时,衬底本身也具备一些特殊的电学、光学和机械特性,这些特性对于半导体的性能至关重要。 Substrate, as a wafer made of semiconductor single crystal material, can either directly enter the wafer manufacturing process and be used to produce semiconductor devices; it can also be processed through epitaxial processes to produce epitaxial wafers. The semiconductor substrate is like a "foundation" that supports the entire semiconductor structure and ensures that it will not crack or be damaged. At the same time, the substrate itself also has some special electrical, optical and mechanical properties, which are crucial to the performance of semiconductors.

如果把集成电路比作建筑高楼大厦,那么衬底无疑是那稳固的地基。为确保其支撑作用的发挥,这些材料在晶体结构上必须展现出高度的一致性,如同高纯度的单晶硅,其纯净与完美是构建坚固地基的基石。只有当地基坚实可靠,才能确保上方建筑的稳固与完美。简单来说,没有合适的衬底,我们就无法构建出稳定且性能良好的半导体器件。 If an integrated circuit is compared to a high-rise building, then the substrate is undoubtedly the solid foundation. In order to ensure their supporting role, these materials must show a high degree of consistency in their crystal structure. Just like high-purity single crystal silicon, its purity and perfection are the cornerstones of building a solid foundation. Only when the foundation is solid and reliable can the stability and perfection of the building above be ensured. Simply put, without the right substrate, we cannot build stable and well-performing semiconductor devices.

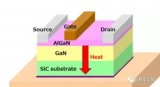

外延 Epitaxy 外延,是指在经过精心切磨抛光的单晶衬底上,精准生长一层全新单晶的过程。这层新单晶既可与衬底材质相同(同质外延),也可不同(异质外延)。由于新生单晶层严格遵循衬底晶相延伸生长,因此被称为外延层,其厚度通常控制在几微米级别。以硅为例,外延生长即在特定晶向的硅单晶衬底上,形成一层晶向一致、电阻率和厚度各异、晶格结构完整的新晶体。经过外延生长的衬底则被称为外延片,其核心价值在于外延层,而器件制作正是围绕这一层展开。 Epitaxy refers to the process of accurately growing a new layer of single crystal on a carefully cut and polished single crystal substrate. This new single crystal can be made of the same material as the substrate (homoepitaxial) or different (heteroepitaxial). Because the new single crystal layer strictly follows the crystalline phase of the substrate and grows, it is called an epitaxial layer, and its thickness is usually controlled at the level of a few microns. Taking silicon as an example, epitaxial growth is to form a layer of new crystals with the same crystal orientation, different resistivities and thicknesses, and a complete lattice structure on a silicon single crystal substrate with a specific crystal orientation. The epitaxially grown substrate is called an epitaxial wafer. Its core value lies in the epitaxial layer, and device production revolves around this layer. 外延片的价值体现在其巧妙的材料组合上。例如,通过在成本较低的硅片上生长一层薄薄的GaN外延,便能以相对低廉的第一代半导体材料为衬底,部分实现昂贵且性能卓越的第三代半导体宽禁带特性,实现高性价比。然而,异质外延结构也伴随着一系列挑战,如晶格失配、温度系数不一致及热传导不良等问题,如同将脚手架搭建在塑料地基上,不同材质在温度变化时会产生膨胀收缩差异,且硅的导热性能并不理想。

The value of epitaxial wafers is reflected in their ingenious combination of materials. For example, by growing a thin layer of GaN epitaxy on a lower-cost silicon wafer, it is possible to partially realize the wide bandgap characteristics of expensive and excellent third-generation semiconductors using relatively inexpensive first-generation semiconductor materials. , achieving high cost performance. However, heteroepitaxial structures are also accompanied by a series of challenges, such as lattice mismatch, inconsistent temperature coefficients and poor thermal conductivity. Just like building scaffolding on a plastic foundation, different materials will have differences in expansion and contraction when the temperature changes, and Silicon's thermal conductivity is not ideal.

同质外延,即在衬底上生长与衬底材料相同的外延层,其意义在于进一步提升产品的稳定性和可靠性。尽管材料相同,但通过外延处理,晶圆表面的材料纯度和均匀度得以显著提升。相比机械抛光的抛光片,外延片表面更为平整、洁净,微缺陷和杂质大幅减少,电阻率更加均匀,对表面颗粒、层错、位错等缺陷的控制也更加精确。因此,外延技术不仅优化了产品性能,更确保了产品的稳定与可靠。

Homoepitaxy, that is, growing an epitaxial layer that is the same as the substrate material on the substrate, is meant to further improve the stability and reliability of the product. Although the materials are the same, the material purity and uniformity on the wafer surface are significantly improved through epitaxy processing. Compared with mechanically polished polished wafers, the surface of epitaxial wafers is smoother and cleaner, with significantly reduced micro-defects and impurities, more uniform resistivity, and more precise control of defects such as surface particles, stacking faults, and dislocations. Therefore, epitaxy technology not only optimizes product performance, but also ensures product stability and reliability.

总结 Summary

在现代电子、光电子、微电子和信息技术领域,半导体衬底和外延技术都发挥着不可或缺的作用。它们为制造高性能、高可靠性的半导体器件提供了坚实的基础。随着科技的不断发展,半导体衬底和外延技术也将不断进步,为未来的半导体产业带来新的突破和发展。

In the fields of modern electronics, optoelectronics, microelectronics and information technology, semiconductor substrates and epitaxial technologies play an indispensable role. They provide a solid foundation for manufacturing high-performance, high-reliability semiconductor devices. With the continuous development of science and technology, semiconductor substrate and epitaxial technology will also continue to advance, bringing new breakthroughs and developments to the future semiconductor industry.

审核编辑:黄飞

-

集成电路

+关注

关注

5388文章

11541浏览量

361726 -

半导体芯片

+关注

关注

60文章

918浏览量

70622

原文标题:小科普:半导体衬底和外延有什么区别?

文章出处:【微信号:深圳市赛姆烯金科技有限公司,微信公众号:深圳市赛姆烯金科技有限公司】欢迎添加关注!文章转载请注明出处。

发布评论请先 登录

相关推荐

半导体制造之外延工艺详解

常见几种SOI衬底及隔离的介绍

CMOS工艺一般都是用P衬底而不是N衬底?两者有什么区别啊?

不同衬底风格的GaN之间有什么区别?

《炬丰科技-半导体工艺》GaN 基板的表面处理

几种led衬底的主要特性对比 氮化镓同质外延的难处

半导体器件为什么要有衬底及外延层之分呢?外延层的存在有何意义?

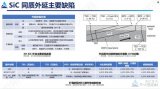

清软微视周继乐:化合物半导体衬底和外延缺陷无损检测技术

半导体衬底材料的选择

半导体衬底和外延有什么区别?

半导体衬底和外延的区别分析

半导体衬底和外延的区别分析

评论