The edge of technology is when it enables you to do something that you couldn't do before. It's one thing to put your imagination down onto a piece of paper, or into a computer program, but what if you could hold it in your hands? This is the vision of 3D printing. Digital designs can be turned into real objects using various kinds of plastic. This technology is not new, but bringing the machine home with you is — the people behind MakerBot started the company with a goal of making 3D printing more accessible.

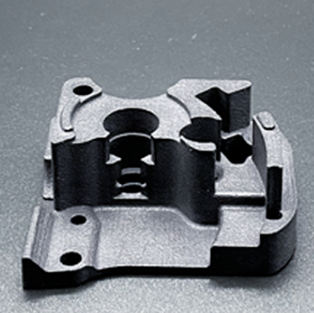

Along with an affordable 3D printing solution has come a community of makers. They're able to share designs, so if you see a picture of something you like, there's a chance you can just make it yourself — by printing it out. For industrial designers, this can speed up prototyping, but for everyone, it's a tangible expression of the imagination — which should, in turn, bring about more innovation.

SEE ALSO: Everything You Wanted to Know About 3D Printing But Were Too Afraid to Ask

MakerBot considers itself to be part of the next industrial revolution. It enables everyone from hobbyists to doctors to professional industrial designers to turn virtual designs into tangible products with MakerBot's line of 3D printers. Founder Bre Pettis tells us more about the capabilities of his products and the MakerBot community.

Q&A with Bre Pettis, Founder of MakerBot

What first inspired MakerBot?

At Makerbot we’re out to change the world, to fuel the next industrial revolution. The company started because we wanted a 3D printer, but they were too expensive and we couldn't afford one, so we played around with one as a hobby for a few years. When it almost worked, we quit our jobs and started MakerBot. Our first printer was a hobbyist printer, and we just launched the Replicator 2, which is a desktop 3D printer that is targeted at professionals who want a 3D printer on their desk or at home. It's also great for amateurs and entrepreneurs, and we’ve got a third layer, which is parents and educators.

How is MakerBot making 3D printing approachable?

With professionals, we’ve got industrial designers, engineers and architects, and they use it to make prototyping go a lot faster. Before MakerBot, when you wanted to have something prototyped you either had to be at an elitist institution, or it took a lot of time — maybe up to a month. When you have a MakerBot on your desk, it can take just minutes or hours, and instead of doing one iteration in a month, you can do multiple iterations in a day. It totally changes the acceleration of innovation, in a good way.

Then we’ve got entrepreneurs — so many times on Kickstarter, there’s between five and 10 things using MakerBot to show the prototype. They’ll do low number runs, less than 1,000, or just be using it to show the what the final product looks like.

“We’re out to change the world, to fuel the next industrial revolution."

Then there’s folks in the medical world — doctors who are using it to take a CAT scan can literally print out what a tumor looks like before they do surgery, so they can hold it in their hands — it's exciting, and there's a lot of interesting work being done in the prosthetics world. People are using 3D printing and MakerBot to create prosthetics to replace things that used to cost $1,000, they can now cost just a few dollars. It might not last as long because it’s plastic instead of metal, but you can make a new one on demand whenever you want. If you grow and want to adjust it, it’s that much easier. We’re at the beginning of this really special time where people have access to the technology, so for us, it’s our mission to empower creative people everywhere and we’re giving them this superpower to make the things that they need.

SEE ALSO: Woman Gets Jawbone Made by 3D Printer

What was the landscape like before you launched, and how did you know when it the right time for you?

Before we launched, 3D printers were the size of refrigerators or bigger. It was kind of like the mainframe era of 3D printing. They were really expensive. On the low end there was a $60,000 option, and these printers are all still available, and they go up to $2.5 million when you’re talking about the metal printers and the ultra large, high-end ones. What’s exciting is that a MakerBot is in many cases as good as the 3D printer that’s a lot more expensive. It's just opening up the whole landscape to people who haven’t had access to it.

In the mainframe computer days, you had to sneak in on the weekend, to get access to PDP-11. It’s the same thing — that's the way it used to be until we brought 3D printing to the desktop.

We also have a site called Thingiverse. You can put your finger on the pulse of 3D printing, and there's new things every day. I look at Thingiverse every day, and I see everything on there — it’s my favorite thing to do every day. Right now we have featured some dollhouse wicker furniture, a hammer that you can 3D print, a small castle and some holiday trees that you can print out to make holiday decorations. It's such a wonderful frontier right now for anyone who’s looking to get involved. The woman who does the miniature dollhouse furniture is actually a set designer for Broadway plays. The things that she’s sharing are literally models that you can go and see on Broadway. As a bonus, everybody with a MakerBot can make them, too, because they're downloadable. She’s become the go-to person for dollhouse furniture in digital design. Whatever passion you have, the landscape is so wide open that you can be the pioneer in that world. I'm looking forward to seeing when the RC car folks arrive on Thingiverse because there’s room for somebody to be a superstar at that. Nobody’s thrown that gantlet down yet, but it’s just waiting and it’s going to happen this year. They dont necessarily need to have been an expert — they can become an expert and our community will support them. It’s so cool.

What will the next five years in tech be like?

The next industrial revolution is coming, and it’s here for people who are ready to ride the tiger of the future. I’m looking forward to seeing what MakerBot users make, they’re already the smartest people in the world, and now with this tool they’re going to become amazing designers and engineers.

Even on a small scale, you have parents who are getting these — you’re going to have kids growing up with a MakerBot. I’m 40 years old now, and when I was growing up, my family got our first computer in 1981. I’m that kid who grew up with a computer who was a total nerd. And we’re going to see the next generation grow up and the kids who have MakerBots are going to be the ones learning how to design a better future and solve problems.

"The kids who have MakerBots are going to be the ones learning how to design a better future and solve problems."

I think we’re going to see more innovation happen at the granular, grassroots level that used to only happen at the industrial level. It happened to computers first, then it happened to bookstores with the rise of Amazon, and now it’s happening to things. You’re going to see author tools and integration in all kinds of different industries. The physical layer to the Internet.

Where do you find inspiration?

I find inspiration in a lot of places. Good product design, I love cars, I love looking at how the evolution of the car has come around. I get inspired by furniture, I love collecting things on Pinterest — I collect my inspirations on Pinterest so people can see it there. The other place I get inspired is really on Thingiverse, where people are sharing amazing things every day. Every day I go to Thingiverse and get that hit of, “What is innovative in the world today” and I can literally see all the new things that have been shared that you can make — that you couldn't make yesterday.

Images courtesy of Makerbot

自动翻译仅供参考

3D打印技术和制造商的崛起

技术的优势是当它使您能够做一些事情,你不能这样做了。这是一件事把你的想象力下来到一张纸上,或者在计算机程序,但如果你可以拿着它在你的手中?这是3D打印的愿景。数字化设计,可以变成使用各类塑料实物。这种技术并不新鲜,但把机器带回家是 - 背后MakerBot的人开始公司以制作3D打印更容易的目标。

随着经济实惠的3D打印解决方案已经制定者组成的社区。他们能够共享的设计,所以如果你看到你喜欢的东西的图片,还有你可以让自己一个机会 - 通过打印出来。对于工业设计师,这样可以加快原型设计,但对于每个人,这是一个想象的具体表现 - 这应该反过来,带来更多的创新。

参见:一切你想知道的关于3D打印,但太不敢问

MakerBot认为自己是下一次工业革命的一部分。它使每个人都从业余爱好者到医生的专业工业设计师把虚拟设计转化为有形的产品,MakerBot的路线3D打印机。方正布雷松佩蒂斯告诉我们更多关于他的产品和MakerBot社区的能力。

与布雷松佩蒂斯,方正MakerBot的

第一次是什么激发了MakerBot?

在Makerbot我们出改变世界,来推动下一次工业革命。创业之初,因为我们需要一个3D打印机,但它们太昂贵,我们也买不起,所以我们研究了一下一个作为一种业余爱好了几年。当它几乎工作,我们放弃我们的工作,并开始MakerBot。我们的第一个打印机是一个业余爱好者的打印机,我们刚刚推出了复制2,这是针对谁想要在他们的办公桌上或家里有3D打印机专业桌面3D打印机。这也是伟大的业余爱好者和企业家,我们已经得到了第三层,这是家长和教育工作者。

如何MakerBot制作3D打印平易近人?

有了人才,我们有工业设计师,工程师和建筑师,他们用它来制作原型走快了很多。 MakerBot之前,如果你想有一些原型,你要么不得不在一个精英的机构,还是花了大量的时间 - 也许长达一个月。当你有一个MakerBot你的办公桌上,它可以只需要几分钟或几个小时,而不是一个月做一次迭代,你可以在一天内做多次反复。它完全改变创新的加速,在一个好办法。

然后,我们已经得到了企业家 - 这么多次Kickstarter上,有使用MakerBot展示样机五至10件事。他们会做一些低运行,不到1000,或者只是用它来展示最终产品看起来像什么。

“我们出改变世界,来推动下一次工业革命。”

此外,还有人在医学界 - 医生谁正在使用它采取了CAT扫描可以从字面上打印出什么是肿瘤看起来像他们这样做术前,这样他们就可以拿在自己手中 - 这是令人兴奋,而且也有趣了不少正在开展工作,在假肢的世界。人们使用3D打印和MakerBot创造假肢更换的东西,用来花费$ 1,000,他们现在可以成本只有几美元。它可能不会持续的时间,因为它是塑料代替金属,但你可以根据需要一个新的,只要你想。如果你的成长,并希望进行调整,这是容易得多。我们在这个非常特殊的时期,人们有机会获得该技术的开始,所以对我们来说,这是我们的使命是赋予有创意的人无处不在,我们给他们这样的超级大国,使他们需要的东西。

参见:女人得到颚骨由3D打印机

什么是你推出之前,类似的景观,和你怎么知道什么时候的最佳时机吗?

在我们推出的3D打印机是冰箱或更大的尺寸。这是一种像大型机时代3D打印的。他们真的很昂贵。在低端有一个$ 60,000个选项,这些打印机都仍然可用,他们上升到$ 2.5万安时你谈论的金属打印机和超大型,高端的。什么是令人兴奋的是,MakerBot在许多情况下不如3D打印机是贵了不少。这只是打开了整个景观还没有对它的访问谁的人。

在电脑主机日子里,你必须潜入周末,以获得进入PDP-11。这是同样的事情 - 这是它曾经是,直到我们把3D打印到桌面的方式。

我们也有一个名为Thingiverse网站。你可以把3D打印的脉搏手指,每天有新的东西。我每天看Thingiverse,和我看到的一切在那里 - 这是我喜欢做的事的每一天。现在,我们有一些特色的娃娃屋柳条家具,一把锤子,你可以3D打印,小城堡和一些节日树,你可以打印出来,使节日装饰。它是这样一个美妙的前沿,现在的人谁的希望参与进来。谁做微型玩偶家具的女人实际上是一组设计师百老汇戏剧。说她分享的东西是字面上的模型,你可以去看看百老汇。作为奖励,每个人都用MakerBot可以让他们,也因为它们是下载。她成为去到人的娃娃屋家具数码设计。无论你的热情有,景观是如此之大了,你可以在这个世界的先驱。我期待着看到当车模的乡亲到达Thingiverse,因为有足够的空间供人成为一个超级巨星在那。没有人抛出的长手套还没有下来,但它只是等待,它会在今年发生。他们不必然需要一直专家 - 他们可以成为专家,我们的社会将支持他们。这太酷了。

什么将在高科技,未来五年是怎样的?

下一次工业革命的到来,它在这里的人谁愿意骑未来的老虎。我很期待看到什么MakerBot用户进行,他们已经在最聪明的人在世界上,现在有了这个工具,他们将成为惊人的设计师和工程师。

即使是小规模的,你还有父母谁是得到这些 - 你将有孩子长大了MakerBot。我40多岁了,当我长大的时候,我的家人得到了我们的第一台电脑在1981年,我的孩子谁长大了一台电脑谁是一个总的书呆子。我们将看到下一代的成长,谁拥有MakerBots孩子将是那些学习如何设计一个更美好的未来和解决的问题。

“谁拥有MakerBots孩子们将是那些学习如何设计一个更美好的未来和解决问题。”

我认为我们将看到更多的创新发生在粒状,基层是用于只发生在工业水平。它发生在计算机首次,那么它发生在书店与亚马逊的崛起,而现在它正在发生的事情。你会看到各种不同行业的作者工具和整合。物理层到互联网。

你在哪里寻找灵感?

我找到灵感了很多地方。良好的产品设计,我喜欢汽车,我喜欢看着怎么坐车的演变过来。我得到灵感的家具,我喜欢收集东西Pinterest的 - 我收集Pinterest的我的灵感,使人们可以看到它。其他的地方我得到的启发是真的在Thingiverse,那里的人们每天都在分享令人惊奇的事情。我每天去Thingiverse和获得,即打“什么是创新的当今世界”,我可以从字面上看到所有已共享,可以使新的东西 - 你不能昨天做。

-

3D打印

+关注

关注

26文章

3539浏览量

108808

发布评论请先 登录

相关推荐

联泰科技亮相2024 亚洲3D打印、增材制造展览会 (TCT Asia 2024)

3D打印技术和制造商的崛起

3D打印技术和制造商的崛起

评论