There are basically two ways to go about making multi-material objects with photopolymer resin-based 3D printing processes. One is based on material science?and uses inkjet 3D printing technologies, such as Stratasys’ Polyjet and 3D Systems’ MJM, to release and instantly cure different materials in the same print job.? Another is mechanical, which is what 3D Systems’ presented around this time last year.

This latest approach is similar to the one implemented by Reinout Holtrop, a student from the University of Twente, for his Final Bachelor Assignment in Industrial Design, to design, develop and build the first DLP-based multi-material 3D printer, which he named XZEED. Ultimately, the basic concept behind the machine is relatively simple: using five alternating petri dishes in borosilicate glass with a PDMS layer, on a moving vat carrier.

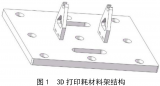

This is the key component in the XZEED machine. It is made up of two shafts with bearings which support a movable array with the round vats. Light is projected with a beamer via a mirror on the bottom of the vat. The build platform is then moved vertically by the z-spindle, while the the x-spindle moves the array to change the vat.

Holtrop studied several 3D printers before developing his own design, including, of course, the industry leading Perfactory series by EnvisionTEC and CLIP technology by Carbon3D. He based his own project on a manual of how to design a normal DLP printer published by Tristram Budel in 2013, which is based on a Ramps 1.4 motherboard placed on top of an Arduino Mega 2560. This?simplified building and setting up the firmware.

The beamer that he used for this project is a Benq PB7230 DLP beamer. It works at the XGA resolution (1024×768) and was modified to be able to have a shorter throw. Perhaps the most amazing aspect is that almost all of the other components, which give the machine a highly professional and solid appearance, were manufactured with readily available in-house rapid prototyping tools. Using CNC mills, laser cutters and 3D printers, enabled Holtrop to work with PMMA plastics for the hood, as well as metal and MDF parts.

Apparently the project is still in its infancy, as Holtrop has stated several further areas of research, including experimenting with resin thickness, the light source (using LED’s instead of a projector), and improving the stability of the vats by building them using a more flexible material. For sure, this is a project that will draw quite a bit of attention from the industry and it will be very interesting to find out how and when it will grow into a commercial product.

自动翻译仅供参考

特温特大学的学生组建了多材料型3D打印机

基本上有两种方式来制造基于光聚合物树脂的3D打印过程的多材料对象。一是以材料科学为基础的?使用喷墨3D打印技术,如Stalasy' Pyj射流和3D系统的MJM,在同一打印作业中释放和即时固化不同的材料。另一种是机械式的,这就是3D系统在去年这个时候提出的。

这个最新的方法类似于通过Reinout Holtrop,从特文特大学,为他最后的学士学位分配在工业设计学生,实行设计,开发和建设的第一个基于DLP的多材料的3D打印机,这是他命名为一XZEED。最终,在机器后面的基本概念是相对简单:使用五个交替在硼硅玻璃培养皿用PDMS层,一个活动大桶载体上。

这是在XZEED机的关键部件。它是由两轴与支持一个可动阵列与轮大桶轴承。光被投射以经由在缸的底部反射镜一个投影仪。构建平台然后垂直移动由与z主轴,而在x-主轴移动阵列,以改变大桶。

Holtrop发展自己的设计,包括,当然,业界领先的Perfactory一系列EnvisionTEC和CLIP技术,通过Carbon3D研究过不少3D打印机。他根据他自己的项目上如何设计由崔斯特瑞姆布德尔在2013年出版了一本普通的DLP打印机,它是基于一个斜坡1.4主板放置在一个Arduino兆2560这上面?简化的建设和设立固件手工。

他用这个项目的投影仪是明基PB7230 DLP投影仪。它工作在XGA分辨率(1024×768),并进行了修改,能够有一个更短的投射。也许最令人惊讶的方面是,几乎所有的其他组件,从而使该机器高度专业和坚实的外观,被制造使用现成的内部快速原型开发工具。采用数控铣床,激光切割机和3D打印机,使Holtrop用PMMA塑料引擎盖,以及金属和中纤板的部分工作。

显然,该项目仍处于起步阶段,作为Holtrop曾表示研究一些其他领域,包括与树脂厚度,光源实验(采用LED的,而不是一台投影仪),以及用更建立他们提高了大桶的稳定性柔性材料。可以肯定,这是一个项目,该项目将吸引相当多的注意力从行业,这将是非常有趣的,以了解如何以及何时会成长为一个商业产品。

-

3D打印

+关注

关注

26文章

3543浏览量

108848

发布评论请先 登录

相关推荐

应用在3D打印机的BD系列金属连接器

Klipper固件的打印机可以插卡打印吗?

2024年含直线电机3D打印机在内共出口182.9万台

UltiMaker正式推出了工业级3D打印机—UltiMaker Factor 4

YXC晶振 32.768KHz石英振荡器,封装3225,应用于3D打印机

并联式3D打印机的设计与计算

年终好价节 盘点最值得入手的4款3D打印机

特温特大学的学生组建了多材料型3D打印机

特温特大学的学生组建了多材料型3D打印机

评论