Linear Resistance Meter,线性刻度欧姆表

关键字:Linear Resistance Meter

Most analogue multimeters are capable of measuring resistance over quite a wide range of values, but are rather inconvenient in use due to the reverse reading scale which is also non-linear. This can also give poor accuracy due to cramping of the scale that occurs at the high value end of each range. This resistance meter has 5 ranges and it has a forward reading linear scale on each range.The full-scale values of the 5 ranges are 1K, 10K, 100K, 1M &10M respectively and the unit is therefore capable of reasonably accurate measurements from a few tens of ohms to ten Megohms.

Circuit diagram

The Circuit

Most linear scale resistance meters including the present design, work on the principle that if a resistance is fed from a constant current source the voltage developed across that resistance is proportional to its value. For example, if a 1K resistor is fed from a 1 mA current source from Ohm’s Law it can be calculated that 1 volt will be developed across the resistor (1000 Ohms divided by 0.001 amps = 1 volt). Using the same current and resistance values of 100 ohms & 10K gives voltages of 0.1volts (100 ohms / 0.001amps = 0.1volts) & 10 volts (10000 ohms / 0.001amps = 10 volts).

Thus the voltage developed across the resistor is indeed proportional to its value, and a voltmeter used to measure this voltage can in fact be calibrated in resistance, and will have the desired forward reading linear scale. One slight complication is that the voltmeter must not take a significant current or this will alter the current fed to the test resistor and impair linearity. It is therefore necessary to use a high impedance voltmeter circuit.

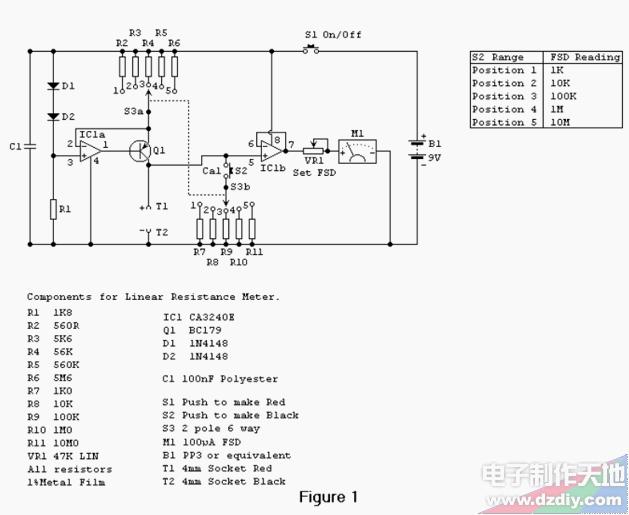

The full circuit diagram of the Linear Resistance Meter is given in Figure 1. The constant current generator is based on IC1a and Q1. R1, D1 and D2 form a simple form a simple voltage regulator circuit, which feeds a potential of just over 1.2 volts to the non-inverting input of IC1a. There is 100% negative feedback from the emitter of Q1 to the inverting input of IC1a so that Q1’s emitter is stabilised at the same potential as IC1a’s non-inverting input. In other words it is stabilised a little over 1.2 volts below the positive supply rail potential. S3a gives 5 switched emitter resistances for Q1, and therefore 5 switched emitter currents. S3b provides 5 reference resistors across T1 & T2 via S2 to set full-scale deflection on each range using VR1.

As the emitter and collector currents of a high gain transistor such as a BC179 device used in the Q1 are virtually identical, this also gives 5 switched collector currents. By having 5 output currents, and the current reduced by a factor of 10 each time S3a is moved one step in a clockwise direction, the 5 required measuring ranges are obtained. R2 to R6 must be close tolerance types to ensure good accuracy on all ranges. The high impedance voltmeter section uses IC1b with 100% negative feedback from the output to the inverting input so that there is unity voltage gain from the non-inverting input to the output. The output of IC1b drives a simple voltmeter circuit using VR1 and M1, and the former is adjusted to give the correct full-scale resistance values.

The CA3240E device used for IC1 is a dual op-amp having a MOS input stage and a class A output stage. These enable the device to operate with the inputs and outputs right down to the negative supply rail voltage. This is a very helpful feature in many circuits, including the present one as it enables a single supply rail to be used where a dual balanced supply would otherwise be needed. In many applications the negative supply is needed simply in order to permit the output of the op-amp to reach the 0volt rail. In applications of this type the CA3240E device normally enables the negative supply to be dispensed with.

As the CA3240E has a MOS input stage for each section the input impedance is very high (about 1.5 million Megohms!) and obviously no significant input current flows into the device. This, together with the high quality of the constant current source, and the practically non-existent distortion through IC1b due to the high feedback level gives this circuit excellent linearity.

With no resistor connected across T1 & T2 M1 will be taken beyond full-scale deflection and overloaded by about 100 or 200%. This is unlikely to damage the meter, but to be on the safe side a push-to-test on/off switch (S1) is used. Thus the power is only applied to the circuit when a test resistor is connected to the unit, and prolonged meter overloads are thus avoided.

A small (PP3 size) 9 volt battery is a suitable power source for this project which has a current consumption of around 5mA and does not require a stabilised supply.

Most linear scale resistance meters including the present design, work on the principle that if a resistance is fed from a constant current source the voltage developed across that resistance is proportional to its value. For example, if a 1K resistor is fed from a 1 mA current source from Ohm’s Law it can be calculated that 1 volt will be developed across the resistor (1000 Ohms divided by 0.001 amps = 1 volt). Using the same current and resistance values of 100 ohms & 10K gives voltages of 0.1volts (100 ohms / 0.001amps = 0.1volts) & 10 volts (10000 ohms / 0.001amps = 10 volts).

Thus the voltage developed across the resistor is indeed proportional to its value, and a voltmeter used to measure this voltage can in fact be calibrated in resistance, and will have the desired forward reading linear scale. One slight complication is that the voltmeter must not take a significant current or this will alter the current fed to the test resistor and impair linearity. It is therefore necessary to use a high impedance voltmeter circuit.

The full circuit diagram of the Linear Resistance Meter is given in Figure 1. The constant current generator is based on IC1a and Q1. R1, D1 and D2 form a simple form a simple voltage regulator circuit, which feeds a potential of just over 1.2 volts to the non-inverting input of IC1a. There is 100% negative feedback from the emitter of Q1 to the inverting input of IC1a so that Q1’s emitter is stabilised at the same potential as IC1a’s non-inverting input. In other words it is stabilised a little over 1.2 volts below the positive supply rail potential. S3a gives 5 switched emitter resistances for Q1, and therefore 5 switched emitter currents. S3b provides 5 reference resistors across T1 & T2 via S2 to set full-scale deflection on each range using VR1.

As the emitter and collector currents of a high gain transistor such as a BC179 device used in the Q1 are virtually identical, this also gives 5 switched collector currents. By having 5 output currents, and the current reduced by a factor of 10 each time S3a is moved one step in a clockwise direction, the 5 required measuring ranges are obtained. R2 to R6 must be close tolerance types to ensure good accuracy on all ranges. The high impedance voltmeter section uses IC1b with 100% negative feedback from the output to the inverting input so that there is unity voltage gain from the non-inverting input to the output. The output of IC1b drives a simple voltmeter circuit using VR1 and M1, and the former is adjusted to give the correct full-scale resistance values.

The CA3240E device used for IC1 is a dual op-amp having a MOS input stage and a class A output stage. These enable the device to operate with the inputs and outputs right down to the negative supply rail voltage. This is a very helpful feature in many circuits, including the present one as it enables a single supply rail to be used where a dual balanced supply would otherwise be needed. In many applications the negative supply is needed simply in order to permit the output of the op-amp to reach the 0volt rail. In applications of this type the CA3240E device normally enables the negative supply to be dispensed with.

As the CA3240E has a MOS input stage for each section the input impedance is very high (about 1.5 million Megohms!) and obviously no significant input current flows into the device. This, together with the high quality of the constant current source, and the practically non-existent distortion through IC1b due to the high feedback level gives this circuit excellent linearity.

With no resistor connected across T1 & T2 M1 will be taken beyond full-scale deflection and overloaded by about 100 or 200%. This is unlikely to damage the meter, but to be on the safe side a push-to-test on/off switch (S1) is used. Thus the power is only applied to the circuit when a test resistor is connected to the unit, and prolonged meter overloads are thus avoided.

A small (PP3 size) 9 volt battery is a suitable power source for this project which has a current consumption of around 5mA and does not require a stabilised supply.

Photos showing inside and outside of the completed Linear Resistance Meter.

Author: Dave Elliott

Email: portagepal@tiscali.co.uk

Email: portagepal@tiscali.co.uk

声明:本文内容及配图由入驻作者撰写或者入驻合作网站授权转载。文章观点仅代表作者本人,不代表电子发烧友网立场。文章及其配图仅供工程师学习之用,如有内容侵权或者其他违规问题,请联系本站处理。

举报投诉

发布评论请先 登录

相关推荐

ADGS2414D: 0.56 Ω On Resistance High Density Octal SPST Switch Data Sheet adi

资料,ADGS2414D: 0.56 Ω On Resistance High Density Octal SPST Switch Data Sheet真值表,ADGS2414D: 0.56

发表于 01-15 18:51

TPL5010的Digital conversion of external resistance (Rext)功耗是怎么计算的?

Datasheet的7.5中有关于Digital conversion of external resistance (Rext)的功耗,

请问,这个功耗应该怎么理解,和总体功耗有什么关系?

发表于 11-08 08:09

请问TAS3251的DAC output可以用来接VM meter吗?

请问 TAS3251 的 DAC output 可以用来接 VM meter 吗?

还是有哪些讯号可以搭接VM meter

谢谢

发表于 10-14 06:55

电流计改装成电压表时刻度怎么刻

将电流计改装成电压表时,刻度的刻画是一个关键步骤,它确保了改装后的电压表能够准确地测量电压。以下是步骤和原理: 一、改装原理 电流计改装成电压表的主要原理是通过串联一个电阻(称为分压电

万用表测电阻黑表笔接哪个极

万用表测电阻时,黑表笔接的极性与万用表的类型(指针式或数字式)有关。 指针式万用表 对于指针式万用表,在测量电阻时,黑表笔连接的是欧姆表内部

欧姆表倍率与内阻的关系

欧姆表是一种用于测量电阻的便携式电子仪器,广泛应用于电子、电气和通信领域。它的原理基于欧姆定律,即电压与电流成正比,而电阻则是电压与电流的比值。在实际应用中,欧姆表的倍率是一个关键参数,它直接影响

什么定律体现了线性电路元件上电压 欧姆定律在实际电路中的应用

线性电路元件上的电压与电流之间的关系遵循欧姆定律。 1. 欧姆定律的基本概念 欧姆定律是描述电阻、电压和电流之间关系的定律。在最简单的形式中,欧姆

非线性电路欧姆定律适用吗

非线性电路是指电路元件的电压与电流之间的关系不是线性的,即不满足欧姆定律的电路。欧姆定律是描述线性电路中电压、电流和电阻之间关系的定律,其表

源表的定义、原理和应用领域

在电子测量与测试领域,源表(Source Measure Unit,简称SMU)是一种重要的测试工具,它集合了电压源、电流源、电压表、电流表、欧姆表及电子负载的功能于一身,为工程师们提

欧姆表的使用步骤和注意事项

欧姆表是一种用于测量电阻的电子测试仪器,广泛应用于电气和电子领域的电阻测量。正确使用欧姆表对于获得准确的测量结果至关重要。

欧姆表机械调零和欧姆调零是什么意思

欧姆表是一种用于测量电阻的电子测试仪器,其测量原理基于欧姆定律。在使用欧姆表测量电阻之前,通常需要进行两种调零操作:机械调零和欧姆调零。这

欧姆表是怎么调零的?欧姆表调零步骤?

欧姆表是一种用于测量电阻的电子仪器,它基于欧姆定律工作。在使用欧姆表测量电阻之前,必须进行调零操作以确保测量的准确性。

微欧表的工作原理和应用领域

微欧表,又称微欧姆表或数字微欧计,是一种专门用于测量微小电阻值的精密电子仪器。在电子工程、电气工程、电力系统和科研实验等领域,微小电阻的测量往往具有极其重要的意义。微欧表以其高精度、高灵敏度

指针式万用表的使用方法

在使用指针式万用表之前,需要观察万用表的指针是否与零刻度线对齐和重合。如果不重合,就需要进行调零操作,否则会影响读数,使测量结果不准确。调零操作包括机械调零和欧姆调零。机械调零是通过调

Linear Resistance Meter,线性刻度欧姆表

Linear Resistance Meter,线性刻度欧姆表

评论