Cree to Invest $1 Billion to Expand Silicon Carbide Capacity

Cree将投资10亿美元,扩大SiC碳化硅产能

Advanced manufacturing campus will accelerate industry transitionfrom silicon to silicon carbide to meet EV and 5G market demand

先进的制造园区,将加速从Si硅向SiC碳化硅的产业转型,满足EV电动汽车和5G市场需求

Expansion to generate up to a 30-fold increase in SiC wafer fabrication capacity and 30-fold increase in SiC materials production to meet the expected market growth by 2024

此次产能扩大,将带来SiC碳化硅晶圆制造产能的30倍增长和SiC碳化硅材料生产的30倍增长,以满足2024年之前的预期市场增长

Five-year investment leverages an existing building (“North Fab”) and refurbished 200mm equipment to build state-of-the-art automotive-qualified production facility

5年的投资,充分利用现有的建筑设施North Fab,并整新200mm设备,建造采用最先进技术的满足汽车认证的生产工厂

Investment: $450M for North Fab; $450M for materials mega factory; and $100M in other investments associated with growing the business

投资:4.5亿美元用于North Fab;4.5亿美元用于材料超级工厂(mega factory);1亿美元用于伴随着业务增长所需要的其它投入

▲ Cree North Fab

DURHAM, N.C., May 7, 2019 – As part of its long-term growth strategy, Cree, Inc. (Nasdaq: CREE) announces it will invest up to $1 billion in the expansion of its silicon carbide capacity with the development of a state-of-the-art, automated 200mm silicon carbide fabrication facility and a materials mega factory at its U.S. campus headquarters in Durham, N.C. It marks the company’s largest investment to date in fueling its Wolfspeed silicon carbide and GaN on silicon carbide business. Upon completion in 2024, the facilities will substantially increase the company’s silicon carbide materials capability and wafer fabrication capacity, allowing wide bandgap semiconductor solutions that enable the dramatic technology shifts underway within the automotive, communications infrastructure and industrial markets.

2019年5月7日,美国北卡罗莱纳州达勒姆讯 – Cree, Inc. (Nasdaq: CREE) 宣布,作为公司长期增长战略的一部分,将投资10亿美元用于扩大SiC碳化硅产能,在公司美国总部北卡罗莱纳州达勒姆市建造一座采用最先进技术的自动化200mm SiC碳化硅生产工厂和一座材料超级工厂。这项标志着公司迄今为止最大的投资,将为Wolfspeed SiC碳化硅和GaN-on-SiC碳化硅基氮化镓业务提供动能。在2024年全部完工之后,这些工厂将极大增强公司SiC碳化硅材料性能和晶圆制造产能,使得宽禁带半导体材料解决方案为汽车、通讯设施和工业市场带来巨大技术转变。

“We continue to see great interest from the automotive and communications infrastructure sectors to leverage the benefits of silicon carbide to drive innovation. However, the demand for silicon carbide has long surpassed the available supply. Today, we are announcing our largest-ever investment in production to dramatically increase this supply and help customers deliver transformative products and services to the marketplace,” said Gregg Lowe, CEO of Cree. “This investment in equipment, infrastructure and our workforce is capable of increasing our silicon carbide wafer fabrication capacity up to 30-fold and our materials production by up to 30-fold compared to Q1 of fiscal year 2017, which is when we began the first phase of capacity expansion. We believe this will allow us to meet the expected growth in Wolfspeed silicon carbide material and device demand over the next five years and beyond.”

Cree首席执行官Gregg Lowe先生表示:“我们不断地看到在汽车和通讯设施领域采用SiC碳化硅的优势来驱动创新所产生的巨大效益。但是,现有的供应却远远不能够满足我们对于SiC碳化硅的需求。今天,我们宣布了公司迄今在生产制造的最大投资,将大幅地提升供应,帮助客户为市场提供变革性的产品和服务。这项在设备、基础设施、公司人力方面的巨大投入,将为我们显著扩大产能。与2017财年第一季度(也就是我们开始扩大产能的第一阶段)相比较,能够带来SiC碳化硅晶圆制造产能的30倍增长和材料生产的30倍增长。我们相信这将使得我们能够满足Wolfspeed SiC碳化硅材料和器件在未来5年乃至更长远的预期增长。”

The plan delivers additional capacity for its industry-leading Wolfspeed silicon carbide business with the build out of an existing structure as a 253,000 square-foot, 200mm power and RF wafer fabrication facility as an initial step to serve the projected market demand. The new North Fab is designed to be fully automotive qualified and will provide nearly 18 times more surface area for manufacturing than exists today, initially opening with the production of 150mm wafers. The company will convert its existing Durham fabrication and materials facility into a materials mega factory.

这项计划将为业界领先的Wolfspeed SiC碳化硅业务提供附加产能。通过增建现有的建筑设施,作为面积253,000平方英尺的200mm功率和RF射频晶圆制造工厂,迈出满足预期市场需求的第一步。新的North Fab将被设计成能够全面满足汽车认证的工厂,其生产提供的晶圆表面积将会是今天现有的18倍,刚开始阶段将进行150mm晶圆的生产。公司将把现有在达勒姆的生产和材料工厂转变为一座材料超级工厂。

“These silicon carbide manufacturing mega-hubs will accelerate the innovation of today’s fastest growing markets by producing solutions that help extend the range and reduce the charge times for electric vehicles, as well as support the rollout of 5G networks around the world,” said Lowe. “We believe that this represents the largest capital investment in the history of silicon carbide and GaN technologies and production with a fiscally responsible approach. By using existing facilities and installing a majority of refurbished tools, we believe we will be able to deliver a state-of-the-art 200mm capable fab at approximately one-third of the cost of a new fab.”

Cree首席执行官Gregg Lowe先生同时还表示:“这些SiC碳化硅制造超级工厂,将加速当今最快增长市场的创新。通过提供解决方案,帮助提高EV电动汽车的行驶里程并减少充电时间,同时支持5G网络在全世界的部署。我们相信这代表着SiC碳化硅和GaN氮化镓技术和制造有史以来最大的资本投资,也是一种在财政上负责任的方式。通过采用现有工厂和安装绝大部分的整新工具,我们相信我们可以实现提供最先进技术的200mm fab,并且成本大约仅为一座新fab的1/3。”

The expanded campus also creates high-tech job opportunities and will serve as an advanced manufacturing workforce development initiative. Cree plans to partner with state and local community and four-year colleges to develop training programs to prepare its workforce for the long-term, high-quality employment and growth opportunities the new facilities will present.

扩大的园区将创造高科技就业机会,并提供先进制造人才发展计划。Cree计划与州、当地和四年制院校开展培训项目,为新工厂所带来的长期、高端就业和成长机遇提供人才储备。

-

Cree

+关注

关注

3文章

91浏览量

34526 -

碳化硅

+关注

关注

25文章

2748浏览量

49019

原文标题:Cree将投资10亿美元,扩大SiC碳化硅产能

文章出处:【微信号:iawbs2016,微信公众号:宽禁带半导体技术创新联盟】欢迎添加关注!文章转载请注明出处。

发布评论请先 登录

相关推荐

碳化硅SiC在光电器件中的使用

碳化硅SiC在高温环境下的表现

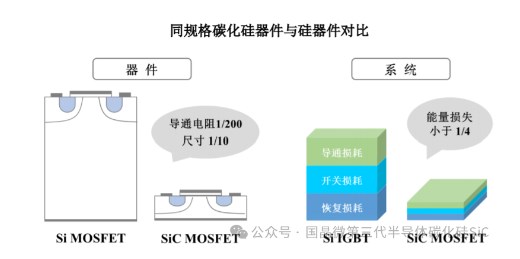

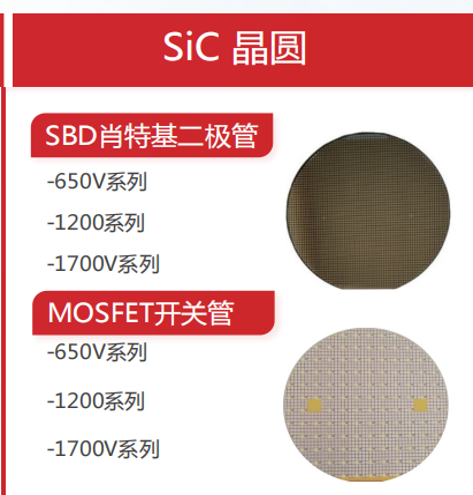

碳化硅SiC制造工艺详解 碳化硅SiC与传统半导体对比

碳化硅SiC在电子器件中的应用

碳化硅SiC材料应用 碳化硅SiC的优势与性能

碳化硅功率器件的工作原理和应用

碳化硅功率器件的优点和应用

英国公司Clas-SiC考虑在印度建设碳化硅工厂

碳化硅模块(SiC模块/MODULE)大电流下的驱动器研究

SK Siltron获美政府投资,扩大碳化硅晶圆厂产能

SIC 碳化硅认识

碳化硅压敏电阻 - 氧化锌 MOV

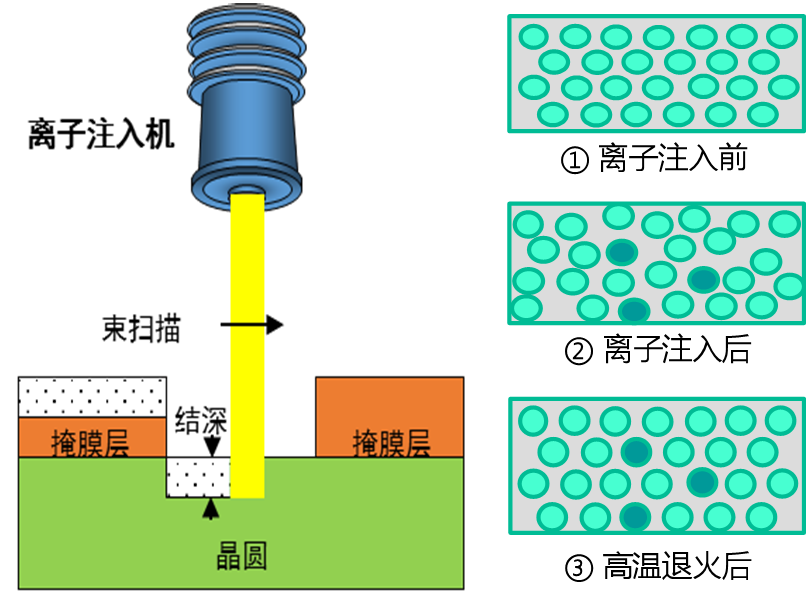

碳化硅特色工艺模块简介

Cree将投资10亿美元 扩大SiC碳化硅产能

Cree将投资10亿美元 扩大SiC碳化硅产能

评论