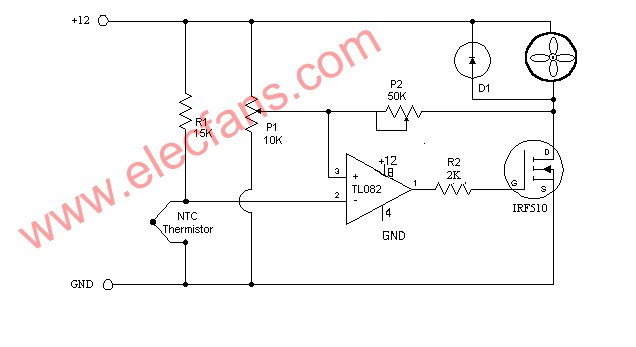

Abstract: Controlling the speed of a brushless DC cooling fan is discussed. Examples of discrete and IC fan speed controllers are shown. 12V, 24V and 48V designs are included, as well as isolated versions. Tachometer feedback for speed control is discussed.

Speed control of the brushless DC fans commonly used in PCs and other types of electronic equipment is complicated by their nonlinear behavior. As Figure 1 shows, the motors do not run at all until the voltage reaches a highly variable startup voltage and the speed is only approximately linear beyond that point.

Figure 1. This graph shows the voltage vs. speed for a typical brushless DC fan. The fan turning starts somewhere between 3 to 5 volts. Predicting the exact starting voltage is difficult. The exact point varies from fan-to-fan, over the fan's operating life, and as a function of ambient conditions. Although the graph is linear above the starting point, most fans only approximate a linear relationship of voltage to speed. Closed loop fan speed regulation overcomes all of these difficulties.

Circuits which regulate fan speed can overcome these difficulties. The availability of motors with tachometer outputs facilitates the design of these circuits.

These systems are "open loop" and subject to start-up voltage requirements. A common approach is to feed full voltage to the fan for a short interval before lowering it to acheive the desired speed. The lowest feasible speed is determined empirically and because it varies with time and conditions, it requires constant re-verification.

Figure 2 depicts a schematic for a simple DAC-based "open loop" fan control. It is subject to the start-up limitations. While often used with fans equipped with tachometer outputs, the ICs only use these tachometer signals to monitor fan speed and determine if speed falls below "watchdog" limits. Because these tachometer signals are so prevalent, the opportunity readily exists to close the loop on fan control.

Figure 2. Simple open-loop fan control is provided by some Health-Monitor, Super I/Os, and fan controllers typified by the MAX1669. This could be implemented with any DAC and any interface. The Health Monitor ICs have always had inputs for the tachometer, but only as a watchdog function, so the host system can verify that the fan is running at minimum rate. The tach signal is not directly used in fan control. Because of start-up issues, some of the DAC range is thrown away resulting in a system that might actually have less than 7-bits of control over fan speed from an 8-bit DAC.

Figure 3. This closed loop fan control amplifier, for use with ICs such as those shown in Figure 2, uses the tachometer signals for feedback. This provides linear control over the full output range of the DAC. The fan will reliably start at any setting without the need to take the fan to full speed first.

The time constant of the differentiator is initially set to provide pulses just shorter than the duration of the shortest tach pulse at full fan speed. This usually provides too little gain. Gain can be increased by decreasing the value of either R2 or C1. Gain should be set such that the fan just achieves full speed with the full DAC output applied to the input of the amplifier circuit.

The time constant of the integrator is set to provide a smooth response to speed changes without any overshoot or hunting. Typically this is done empirically with the actual fan and system. The plots in Figure 4 and Figure 5 depict the response of the amplifier with the integration capacitor C2 at two values, 0.1µF and 1.0µF. Either value meets customary criteria for stability which dictates less than 25% overshoot.

Figure 4. This plot depicts the closed-loop fan control amplifier with a 0.01µF integrating capacitor responding to a step change input.

Figure 5. This plot depicts the closed-loop fan control amplifier with a 1µF integrating capacitor responding to a step change input.

The MAX6650 is designed to control a single fan. The MAX6651 controls a single fan and can monitor and watchdog three additional fan tachometer outputs. Multiple MAX6651s controlling multiple fans can be synchronized. These ICs are designed to interface to an I²C or SMBus, and use the tachometer feedback from fans to regulate their speed. The ICs include extensive programmability to accommodate a variety of fan speeds and types. Figure 6 depicts a typical connection for the MAX6650.

Note from the circuit of Figure 6 that the MAX6650/MAX6651 are designed to be used with an external pass transistor. Feedback is taken from the drain of the transistor to the terminal on the IC labeled "FB", since the output stage of the MAX6650/MAX6651 is an analog DAC and amplifier combination. This DAC/amplifier combination requires local feedback. The feedback of the complete loop is actually the tachometer signal of the fan, and this is also returned to the MAX6650/MAX6651. These devices will drive the fan until that tach signal matches the programmed period in the speed register in the MAX6650/MAX6651.

Figure 6. The MAX6650 shown here provides a complete integrated, interfaceable solution to fan speed regulation.

When setting the values for these attenuators, the tachometer feedback signal at the TACHO pin should always be kept more positive than the voltage at the FB pin. This is done with a slightly greater attenuation on the FB network. The FB network can actually tolerate a wide range of attenuation since that only sets the local gain of the MAX6650/MAX6651 output stage. That output stage is still enclosed within the greater feedback loop formed by the TACHO signal.

Figure 7 shows a circuit for connecting MAX6650/MAX6651 to higher voltage fans. R1 is selected to be large enough to avoid loading the pull-up resistor, RPULLUP. R1 and R2 are set for an attenuation factor proportional to the increase in voltage above 12 volts. For example, in Figure 7, R1 and R2 attenuate the tach signal to one-fourth of the value at the fan, since the fan operates at 48 volts. Once the attenuation factor for R1 and R2 have been determined, select R3 and R4 to have a somewhat greater attenuation factor so that the feedback voltage is more negative than the tach signal at all times. In Figure 7, the feedback signal is one-fifth the value at the drain of Q1. The relationship between tach and feedback signal is depicted in the scope traces shown in Figure 8. This attenuation relationship is necessary since the tachometer threshold, which is referred to the FB pin, is approximately 1.25 volts above the FB pin.

Figure 7. This circuit enables the MAX6650 to control a 48 volt fan by attenuating the feedback and tachometer signals to levels similar to what a 12 volt fan would produce.

Figure 8. The scope photo on the left is taken at 780 rpm, driving a 48 volt motor. The right trace is taken at 1526 rpm. The square waveform is the tach signal at the TACHO pin of the MAX6650. The straight line is the feedback, taken at the FB pin of the MAX6650. Note that the voltage at the FB pin is more negative than the TACHO pin over the operating range of the fan. This is insured by setting the R3/R4 combination in Figure 7 for slightly more attenuation than the R1/R2 combination.

Figure 9. Isolated fan control circuits are useful where ground noise due to high fan currents can be a problem. IC1 and IC2 comprise a bi-directional digital isolator for the data line. Since the MAX6650/MAX6651 is only an input for clock, unidirectional isolation can be used for the clock with IC3. IC4 is an optional addition to couple.

In Figure 9 a bi-directional optical isolator circuit isolates the data line. The bi-directional isolator circuit has been described previously in references 1 and 2. IC1 and IC2 are connected together in such a way that a low on either side results in a low on the other side, without the isolator circuit latching.

Virtually all of the I²C and SMBus devices discussed here have clock pins that are input only (as opposed to some I²C ICs which can "stretch" the clock by holding the clock low). This simplifies isolation by requiring only a single unidirectional isolator. Most of these devices also have watchdog or alert outputs that can be coupled back to the controller with another unidirectional isolator.

These same methods are readily adaptable to circuits that address more limited needs. Many applications such as telecom use 48 volt fans, and these circuits and ICs can be adapted for that use. Galvanic isolation methods can solve messy ground loop problems that occasionally arise with large fan current spikes.

_____________________

Speed control of the brushless DC fans commonly used in PCs and other types of electronic equipment is complicated by their nonlinear behavior. As Figure 1 shows, the motors do not run at all until the voltage reaches a highly variable startup voltage and the speed is only approximately linear beyond that point.

Figure 1. This graph shows the voltage vs. speed for a typical brushless DC fan. The fan turning starts somewhere between 3 to 5 volts. Predicting the exact starting voltage is difficult. The exact point varies from fan-to-fan, over the fan's operating life, and as a function of ambient conditions. Although the graph is linear above the starting point, most fans only approximate a linear relationship of voltage to speed. Closed loop fan speed regulation overcomes all of these difficulties.

Circuits which regulate fan speed can overcome these difficulties. The availability of motors with tachometer outputs facilitates the design of these circuits.

The Basic Fan Control Amplifier

For some time now there have been integrated circuits available that include a DAC (digital-to-analog converter) for controlling fan speed. These include PC system Health Monitors and dedicated fan control ICs, such as the MAX1669, with either a linear DAC output as well as PWM output. Although primarily designed for use in PCs, these ICs have found use in other types of electronic equipment. They are equipped with I²C or SMBus interfaces for communication with the controller, processor, or computer. Typically the DAC outputs are fed into either of two types of analog amplifier circuits to step up their voltage output for application to a fan.These systems are "open loop" and subject to start-up voltage requirements. A common approach is to feed full voltage to the fan for a short interval before lowering it to acheive the desired speed. The lowest feasible speed is determined empirically and because it varies with time and conditions, it requires constant re-verification.

Figure 2 depicts a schematic for a simple DAC-based "open loop" fan control. It is subject to the start-up limitations. While often used with fans equipped with tachometer outputs, the ICs only use these tachometer signals to monitor fan speed and determine if speed falls below "watchdog" limits. Because these tachometer signals are so prevalent, the opportunity readily exists to close the loop on fan control.

Figure 2. Simple open-loop fan control is provided by some Health-Monitor, Super I/Os, and fan controllers typified by the MAX1669. This could be implemented with any DAC and any interface. The Health Monitor ICs have always had inputs for the tachometer, but only as a watchdog function, so the host system can verify that the fan is running at minimum rate. The tach signal is not directly used in fan control. Because of start-up issues, some of the DAC range is thrown away resulting in a system that might actually have less than 7-bits of control over fan speed from an 8-bit DAC.

Closed Loop Fan Control Amplifier

An enhancement can be made to DAC drive fan controllers with the use of an external amplifier that closes the loop around the tachometer. This provides essentially linear control over the full range of 8-bit DAC codes from 0 to 255. Since the tachometer is already there, this only requires a little signal conditioning and a suitable amplifier arrangement. In the circuit shown in Figure 3, the tachometer pulses are conditioned such that all pulse width information is removed (differentiated) and only pulse rate information remains. These pulses representing frequency or fan speed are then used as the feedback to an integrating motor control amplifier.

Figure 3. This closed loop fan control amplifier, for use with ICs such as those shown in Figure 2, uses the tachometer signals for feedback. This provides linear control over the full output range of the DAC. The fan will reliably start at any setting without the need to take the fan to full speed first.

The time constant of the differentiator is initially set to provide pulses just shorter than the duration of the shortest tach pulse at full fan speed. This usually provides too little gain. Gain can be increased by decreasing the value of either R2 or C1. Gain should be set such that the fan just achieves full speed with the full DAC output applied to the input of the amplifier circuit.

The time constant of the integrator is set to provide a smooth response to speed changes without any overshoot or hunting. Typically this is done empirically with the actual fan and system. The plots in Figure 4 and Figure 5 depict the response of the amplifier with the integration capacitor C2 at two values, 0.1µF and 1.0µF. Either value meets customary criteria for stability which dictates less than 25% overshoot.

Figure 4. This plot depicts the closed-loop fan control amplifier with a 0.01µF integrating capacitor responding to a step change input.

Figure 5. This plot depicts the closed-loop fan control amplifier with a 1µF integrating capacitor responding to a step change input.

Integrated Solutions to Fan Regulation

Fan speed regulation design is simplified greatly by using a dedicated IC such as the MAX6650 or MAX6651.The MAX6650 is designed to control a single fan. The MAX6651 controls a single fan and can monitor and watchdog three additional fan tachometer outputs. Multiple MAX6651s controlling multiple fans can be synchronized. These ICs are designed to interface to an I²C or SMBus, and use the tachometer feedback from fans to regulate their speed. The ICs include extensive programmability to accommodate a variety of fan speeds and types. Figure 6 depicts a typical connection for the MAX6650.

Note from the circuit of Figure 6 that the MAX6650/MAX6651 are designed to be used with an external pass transistor. Feedback is taken from the drain of the transistor to the terminal on the IC labeled "FB", since the output stage of the MAX6650/MAX6651 is an analog DAC and amplifier combination. This DAC/amplifier combination requires local feedback. The feedback of the complete loop is actually the tachometer signal of the fan, and this is also returned to the MAX6650/MAX6651. These devices will drive the fan until that tach signal matches the programmed period in the speed register in the MAX6650/MAX6651.

Figure 6. The MAX6650 shown here provides a complete integrated, interfaceable solution to fan speed regulation.

Controlling High Voltage Fans

Some fans are rated at up to 24 to 48 volts. The MAX6650/MAX6651 can easily be adapted to controlling these higher voltage fans by simply attenuating the feedback and tachometer signals by an amount proportional to the difference between the actual supply and 12 volts. In essence, the MAX6650/MAX6651 can be "tricked" into thinking it is controlling a 12 volt fan. This is accomplished with simple attenuation networks on both the feedback and tachometer outputs.When setting the values for these attenuators, the tachometer feedback signal at the TACHO pin should always be kept more positive than the voltage at the FB pin. This is done with a slightly greater attenuation on the FB network. The FB network can actually tolerate a wide range of attenuation since that only sets the local gain of the MAX6650/MAX6651 output stage. That output stage is still enclosed within the greater feedback loop formed by the TACHO signal.

Figure 7 shows a circuit for connecting MAX6650/MAX6651 to higher voltage fans. R1 is selected to be large enough to avoid loading the pull-up resistor, RPULLUP. R1 and R2 are set for an attenuation factor proportional to the increase in voltage above 12 volts. For example, in Figure 7, R1 and R2 attenuate the tach signal to one-fourth of the value at the fan, since the fan operates at 48 volts. Once the attenuation factor for R1 and R2 have been determined, select R3 and R4 to have a somewhat greater attenuation factor so that the feedback voltage is more negative than the tach signal at all times. In Figure 7, the feedback signal is one-fifth the value at the drain of Q1. The relationship between tach and feedback signal is depicted in the scope traces shown in Figure 8. This attenuation relationship is necessary since the tachometer threshold, which is referred to the FB pin, is approximately 1.25 volts above the FB pin.

Figure 7. This circuit enables the MAX6650 to control a 48 volt fan by attenuating the feedback and tachometer signals to levels similar to what a 12 volt fan would produce.

|

|

Figure 8. The scope photo on the left is taken at 780 rpm, driving a 48 volt motor. The right trace is taken at 1526 rpm. The square waveform is the tach signal at the TACHO pin of the MAX6650. The straight line is the feedback, taken at the FB pin of the MAX6650. Note that the voltage at the FB pin is more negative than the TACHO pin over the operating range of the fan. This is insured by setting the R3/R4 combination in Figure 7 for slightly more attenuation than the R1/R2 combination.

Isolated Fan Drive

In some systems the high fluctuating ground currents of fans cause noise problems due to ground loops. Ground loop problems are readily solved by galvanic isolation. The schematic of Figure 9 can be used to isolate any I²C or SMBus fan controller, including the previously mentioned MAX1669 or MAX6650/MAX6651. The circuit shown takes advantage of the already isolated fan power supply so that the MAX6650/MAX6651 does not have to include a separate expensive isolated 5 volt DC-DC converter. The MAX6330/MAX6331 shunt regulator provides an economical and reliable way to regulate down from the 48 volts. The SOT23 package of the MAX6330/MAX6331 combined with the size of the 5 watt dropping resistor compare favorably to that of a pass regulator and heatsink. Furthermore, the 5 watt resistor is easier and less costly to install than a heatsink.

Figure 9. Isolated fan control circuits are useful where ground noise due to high fan currents can be a problem. IC1 and IC2 comprise a bi-directional digital isolator for the data line. Since the MAX6650/MAX6651 is only an input for clock, unidirectional isolation can be used for the clock with IC3. IC4 is an optional addition to couple.

In Figure 9 a bi-directional optical isolator circuit isolates the data line. The bi-directional isolator circuit has been described previously in references 1 and 2. IC1 and IC2 are connected together in such a way that a low on either side results in a low on the other side, without the isolator circuit latching.

Virtually all of the I²C and SMBus devices discussed here have clock pins that are input only (as opposed to some I²C ICs which can "stretch" the clock by holding the clock low). This simplifies isolation by requiring only a single unidirectional isolator. Most of these devices also have watchdog or alert outputs that can be coupled back to the controller with another unidirectional isolator.

Fan Speed Regulation As Opposed to Fan Speed Control

Closed loop fan control overcomes the inherent non-linearity involved in controlling DC brushless fans. Fan control then becomes fan speed regulation. Precise fan speed is assured even over variations from fan to fan and due to aging. Closed loop fan regulation is readily accomplished with available fan control and health monitoring ICs by using a closed loop amplifier circuit on their output. More recently, ICs are becoming available which provide closed loop fan speed regulation.These same methods are readily adaptable to circuits that address more limited needs. Many applications such as telecom use 48 volt fans, and these circuits and ICs can be adapted for that use. Galvanic isolation methods can solve messy ground loop problems that occasionally arise with large fan current spikes.

_____________________

- "Isolate Data Acquisition on a Bi-directional Bus", Jerry Steele, Electronic Design, November 6, 1995.

- "Temperature sensor uses I²C isolator", Jerry Steele, EDN, June 6, 1996.

电子发烧友App

电子发烧友App

评论