用于MAX7456随屏显示器SPI接口的C程序 |

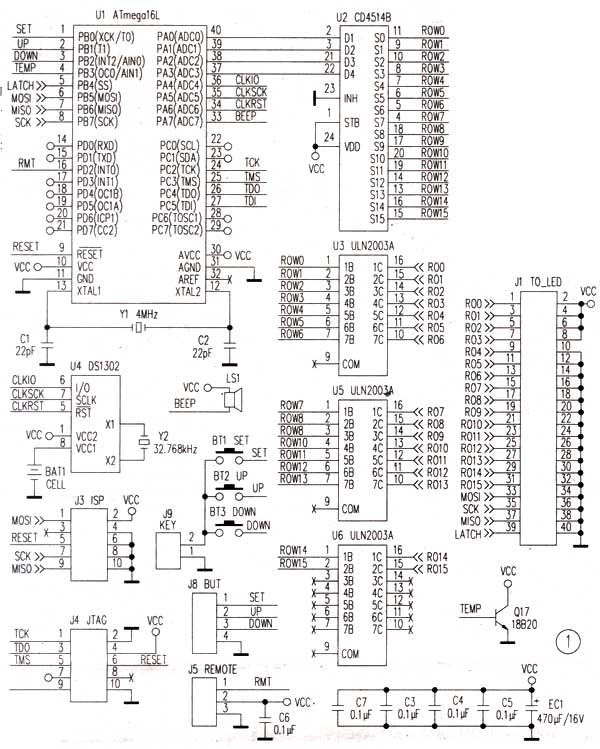

摘要:MAX7456随屏显示(OSD)发生器具有SPI™兼容接口,本应用笔记介绍了SPI接口的工作原理,文中还包含在微控制器内逐位模拟SPI接口的控制器C程序。 MAX7456串行接口MAX7456单通道单色随屏显示(OSD)发生器预装了256个字符和图形,并可通过SPI接口在线编程。通过SPI兼容串行接口可以设置工作模式、显示存储器以及字符存储器。状态(STAT)寄存器、显示存储器数据输出(DMDO)寄存器和字符存储器数据输出(CMDO)寄存器都可读,可以对其进行写操作和读操作。关于MAX7456寄存器及存储器结构的详细信息请参考数据资料和应用笔记4117,"使用MAX7456存储器和评估板文件生成定制字符和图形"。MAX7456支持高达10MHz接口时钟(SCLK)。图1为写数据时序,图2是从器件读数据的时序。 写寄存器时,拉低/CS可使能串行接口。在SCLK的上升沿从SDIN读取数据。当/CS变为高电平时,数据锁存到输入寄存器。如果传输过程中/CS变高,程序终止(即数据不写入寄存器)。/CS变低之后,器件等待从SDIN读入第一个字节,以确定正在执行的数据传输类型。 读寄存器时,如上文所述,拉低/CS。地址在SCLK的上升沿锁入SDIN。然后数据在SCLK的下降沿从SDOUT输出。 SPI命令长度为16位:最高8位(MSB)代表寄存器地址,最低8位(LSB)代表数据(图1和2)。这种格式有两个例外:

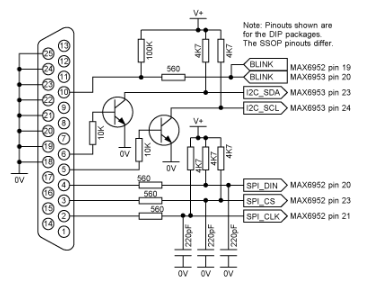

图1. 写操作 图2. 读操作 图3. 自动递增写操作 C程序下文给出的C程序已针对MAXQ2000微控制器进行了编译,用于MAX7456评估(EV)板。本文给出了完整的程序例程。程序是自述文档,几乎没有附加说明。C程序可从以下文件获得:spi.c和MAX7456.h。以下程序使用了SPI协议的标准定义,MAXQ2000处理器为SPI主机,MAX7456是SPI从器件。 CS与MAX7456数据资料中的定义相同。 SDIN对应于MOSI (主机出从器件入)。 SDOUT对应于MOSI (主机入从器件出)。 SCLK对应于CK。 前缀SPI_用于全部程序。 数据结构下文所示数据结构可直接或逐位读写数据,用于独立访问SPI端口。C++和一些较新的C编译器支持位字段联合/结构语句)。/* Port 5 Output Register */

__no_init volatile __io union

{

unsigned char PO5;

struct

{

unsigned char bit0 : 1;

unsigned char bit1 : 1;

unsigned char bit2 : 1;

unsigned char bit3 : 1;

unsigned char bit4 : 1;

unsigned char bit5 : 1;

unsigned char bit6 : 1;

unsigned char bit7 : 1;

} PO5_bit;

}

上述代码将一个单字节赋值给PO5,这是微控制器输出端口的地址。然后将另一个字节赋值给相同的可以逐位访问的存储器地址。因此,可用以下命令直接对该端口进行寻址: PO5 = 0x10; 或用以下命令逐位读写: PO5_bit.bit4 = 1; 如果该程序用于其它处理器,该结构需要重新编写。 如果采用不支持位字段宽度的老式C编译器,可用位布尔运算设置及清除位: /* Portable bit-set and bit-clear macros. */ #define BIT_SET(sfr,bitmask) sfr |= (bitmask) #define BIT_CLR(sfr,bitmask) sfr &=~ (bitmask) #define BIT0 0x01 #define BIT1 0x02 #define BIT2 0x04 #define BIT3 0x08 #define BIT4 0x10 #define BIT5 0x20 #define BIT6 0x40 #define BIT7 0x80 example: BIT_SET(PO5,BIT0); BIT_CLR(PO5,BIT6); 宏以下是一个简单的编程技巧,使程序更容易移植:用宏定义控制器引脚排列,如下所示。#define SPI_CS PO5_bit.bit4 // PO5_bit.bit4 = active-low CS—chip select #define SPI_MOSI PO5_bit.bit5 // PO5_bit.bit5 = MOSI—master out slave in, // data to MAX7456 #define SPI_MISO PI5_bit.bit7 // PO5_bit.bit7 = MISO—master in slave out, // data from MAX7456 #define SPI_CK PO5_bit.bit6 // PO5_bit.bit6 = SCK - SPI clock用以上宏和数据结构可以单独置位及复位每个IO口,命令如下: SPI_CS = 1; 改变宏时相应引脚也将改变,将上述代码用于其它设计时,如果SPI口引脚排列不同,或为了实现更理想的PCB布局而对引脚进行重新排列,上述程序非常有用。 单字节写操作程序单字节写操作(图1)程序如下所示。如果可以保证在程序入口处的/CS和CK线状态正确,可以去掉前两条命令。程序首先发送地址,然后发送数据。进行两次循环。采用单循环及16位数据存储可以简化程序。在MAXQ2000微控制器中执行16位“int”所占用的时间比执行8位“char”长,因此需进行权衡考虑。 /************************************************************************************** * spiWriteReg * * Writes to an 8-bit register with the SPI port **************************************************************************************/ void spiWriteReg(const unsigned char regAddr, const unsigned char regData) { unsigned char SPICount; // Counter used to clock out the data unsigned char SPIData; // Define a data structure for the SPI data SPI_CS = 1; // Make sure we start with active-low CS high SPI_CK = 0; // and CK low SPIData = regAddr; // Preload the data to be sent with Address SPI_CS = 0; // Set active-low CS low to start the SPI cycle // Although SPIData could be implemented as an "int", // resulting in one // loop, the routines run faster when two loops // are implemented with // SPIData implemented as two "char"s. for (SPICount = 0; SPICount < 8; SPICount++) // Prepare to clock out the Address byte { if (SPIData & 0x80) // Check for a 1 SPI_MOSI = 1; // and set the MOSI line appropriately else SPI_MOSI = 0; SPI_CK = 1; // Toggle the clock line SPI_CK = 0; SPIData <<= 1; // Rotate to get the next bit } // and loop back to send the next bit // Repeat for the Data byte SPIData = regData; // Preload the data to be sent with Data for (SPICount = 0; SPICount < 8; SPICount++) { if (SPIData & 0x80) SPI_MOSI = 1; else SPI_MOSI = 0; SPI_CK = 1; SPI_CK = 0; SPIData <<= 1; } SPI_CS = 1; SPI_MOSI = 0; } 读字节操作程序读字节操作(图2)程序如下所示,与上述程序类似。首先发送地址,然后发送时钟从MISO读回数据。/**************************************************************************************

* spiReadReg

*

* Reads an 8-bit register with the SPI port.

* Data is returned.

**************************************************************************************/

unsigned char spiReadReg (const unsigned char regAddr)

{

unsigned char SPICount; // Counter used to clock out the data

unsigned char SPIData;

SPI_CS = 1; // Make sure we start with active-low CS high

SPI_CK = 0; // and CK low

SPIData = regAddr; // Preload the data to be sent with Address and Data

SPI_CS = 0; // Set active-low CS low to start the SPI cycle

for (SPICount = 0; SPICount < 8; SPICount++) // Prepare to clock out the Address and Data

{

if (SPIData & 0x80)

SPI_MOSI = 1;

else

SPI_MOSI = 0;

SPI_CK = 1;

SPI_CK = 0;

SPIData <<= 1;

} // and loop back to send the next bit

SPI_MOSI = 0; // Reset the MOSI data line

SPIData = 0;

for (SPICount = 0; SPICount < 8; SPICount++) // Prepare to clock in the data to be read

{

SPIData <<=1; // Rotate the data

SPI_CK = 1; // Raise the clock to clock the data out of the MAX7456

SPIData += SPI_MISO; // Read the data bit

SPI_CK = 0; // Drop the clock ready for the next bit

} // and loop back

SPI_CS = 1; // Raise CS

return ((unsigned char)SPIData); // Finally return the read data

}

自动递增模式下的写字节操作程序自动递增模式下的写字节操作(图3)程序如下所示,与和上述单字节写程序类似。首先发送地址,然后发送时钟从MISO读回数据。/**************************************************************************************

* spiWriteRegAutoIncr

*

* Writes to an 8-bit register with the SPI port using the MAX7456's autoincrement mode

**************************************************************************************/

void spiWriteRegAutoIncr(const unsigned char regData)

{

unsigned char SPICount; // Counter used to clock out the data

unsigned char SPIData; // Define a data structure for the SPI data.

SPI_CS = 1; // Make sure we start with active-low CS high

SPI_CK = 0; // and CK low

SPIData = regData; // Preload the data to be sent with Address and Data

SPI_CS = 0; // Set active-low CS low to start the SPI cycle

for (SPICount = 0; SPICount < 8; SPICount++) // Prepare to clock out the Address and Data

{

if (SPIData & 0x80)

SPI_MOSI = 1;

else

SPI_MOSI = 0;

SPI_CK = 1;

SPI_CK = 0;

SPIData <<= 1;

} // and loop back to send the next bit

SPI_MOSI = 0; // Reset the MOSI data line

}

自动递增模式下写显示存储器的程序自动递增模式下写显示存储器的程序如下,程序使用称为 "data"的全局变量数组。定义如下:extern volatile unsigned char data[DATA_BUF_LENGTH]; DATA_BUF_LENGTH = 968调用程序时,data[]包含显示存储器内容,格式如下: data[0] = ignored (contains a command byte used by the EV kit GUI software) data[1] = character byte 1 data[2] = attribute byte 1 data[3] = character byte 2 data[4] = attribute byte 2 etc.自动递增模式通过写0xFF结束,所以该模式下不能向显示寄存器写0xFF。如果需要写OxFF,可以采用单字节写指令。 /**************************************************************************************

* spiWriteCM

*

* Writes to the Display Memory (960 bytes) from "data" extern.

* 960 = 16 rows × 30 columns × 2 planes {char vs. attr} screen-position-indexed memory

**************************************************************************************/

void spiWriteCM() // On entry: global data[1..960]

// contains char+attr bytes

// (optionally terminated by 0xFF data)

// First, write data[1,3,5,...] Character plane;

// MAX7456 WriteReg(0x05,0x41)

// "Character Memory Address High";

// 0x02:Attribute bytes;

// 0x01:character memory address msb

{

volatile unsigned int Index = 0x0001; // Index for lookup into

// data[1..960]

spiWriteReg(DM_ADDRH_WRITE,0x00); // initialise the Display Memory high-byte

spiWriteReg(DM_ADDRL_WRITE,0x00); // and the low-byte

spiWriteReg(DM_MODE_WRITE ,0x41); // MAX7456 WriteReg(0x04,0x41) "Display Memory Mode";

// 0x40:Perform 8-bit operation; 0x01:AutoIncrement

Do // Loop to write the character data

{

if (data[Index] == 0xFF) { // Check for the break character

break; } // and finish if found

spiWriteRegAutoIncr(data[Index]); // Write the character

Index += 2; // Increment the index to the next character,

// skipping over the attribute

} while(Index < 0x03C1); // 0x03C1 = 961

// and loop back to send the next character

spiWriteRegAutoIncr(0xFF); // Write the "escape character" to end AutoIncrement

// mode

spiWriteReg(DM_ADDRH_WRITE,0x02); // Second, write data[2,4,6,...]

// Attribute plane; MAX7456

// WriteReg(0x05,0x41)

// "Character Memory Address High";

// 0x02:Attribute bytes; 0x01:character memory address

// msb

spiWriteReg(DM_ADDRL_WRITE,0x00);

spiWriteReg(DM_MODE_WRITE,0x41); // MAX7456 WriteReg(0x04,0x41) "Character Memory

// Mode"; 0x40:Perform 8-bit operation; 0x01:Auto-

// Increment

Index = 0x0002;

do

{

if (data[Index] == 0xFF)

break;

spiWriteRegAutoIncr(data[Index]);

Index += 2;

} while(Index < 0x03C1);

spiWriteRegAutoIncr(0xFF);

}

写字符存储器程序向字符存储器写一个字符的程序如下,每个字符占用18行,每行12像素,共216像素。由于每个字节定义4个像素,因此定义每一个字符需要54字节。字符数据位于程序入口处的data[] (与上述写显示存储器的程序类似)。写字符存储器时需要进行一些附加说明,存储器为非易失,因此,写存储器大约需要12ms,由MAX7456执行。只有完整的54字节字符才可以写入字符存储器。 该器件包含一个54字节映射存储器。首先把需要写入的字符数据写入映射存储器,然后器件将该数据装载到NVM字符存储器。 用来写字符存储器的寄存器有以下几种:

向NVM字符存储器写字符时,首先写字符地址。然后将每个字节写入映射存储器。写映射存储器时没有自动递增模式,所以每次写操作必须写入映射存储器地址。向字符存储器模式寄存器写0xA0,可以把映射存储器的内容装载到NVM字符存储器。然后器件将状态寄存器第5位置高,表明不能写入字符存储器。完成后,器件将该位复位至低。数据从映射存储器移向字符存储器时不能写映射存储器。 为了避免出现显示器闪烁,在写字符存储器之前程序禁止了OSD。 /**************************************************************************************

* spiWriteFM

*

* Writes to the Character Memory (54 bytes) from "data" extern

**************************************************************************************/

void spiWriteFM()

{

unsigned char Index;

spiWriteReg(VIDEO_MODE_0_WRITE,spiReadReg

(VIDEO_MODE_0_READ) & 0xF7); // Clear bit 0x08 to DISABLE the OSD display

spiWriteReg(FM_ADDRH_WRITE,data[1]); // Write the address of the character to be written

// MAX7456 glyph tile definition

// length = 0x36 = 54 bytes

// MAX7456 64-byte Shadow RAM accessed

// through FM_DATA_.. FM_ADDR.. contains a single

// character/glyph-tile shape

for(Index = 0x00; Index < 0x36; Index++)

{

spiWriteReg(FM_ADDRL_WRITE,Index); // Write the address within the shadow RAM

spiWriteReg(FM_DATA_IN_WRITE,data[Index + 2]); // Write the data to the shadow RAM

}

spiWriteReg(FM_MODE_WRITE, 0xA0); // MAX7456 "Font Memory Mode" write 0xA0 triggers

// copy from 64-byte Shadow RAM to NV array.

while ((spiReadReg(STATUS_READ) & 0x20) != 0x00); // Wait while NV Memory status is BUSY

// MAX7456 0xA0 status bit 0x20: NV Memory Status

// Busy/~Ready

}

MAX7456头文件下面列出了MAX7456的头文件,以下代码决定了器件的寄存器映射。/**************************************************************************************

* spiWriteRegAutoIncr

*

* Writes to an 8-bit register with the SPI port by using the MAX7456's autoincrement mode

**************************************************************************************/

// MAX7456 VIDEO_MODE_0 register

#define VIDEO_MODE_0_WRITE 0x00

#define VIDEO_MODE_0_READ 0x80

#define VIDEO_MODE_0_40_PAL 0x40

#define VIDEO_MODE_0_20_NoAutoSync 0x20

#define VIDEO_MODE_0_10_SyncInt 0x10

#define VIDEO_MODE_0_08_EnOSD 0x08

#define VIDEO_MODE_0_04_UpdateVsync 0x04

#define VIDEO_MODE_0_02_Reset 0x02

#define VIDEO_MODE_0_01_EnVideo 0x01

// VIDEO MODE 0 bitmap

#define NTSC 0x00

#define PAL 0x40

#define AUTO_SYNC 0x00

#define EXT_SYNC 0x20

#define INT_SYNC 0x30

#define OSD_EN 0x08

#define VERT_SYNC_IMM 0x00

#define VERT_SYNC_VSYNC 0x04

#define SW_RESET 0x02

#define BUF_EN 0x00

#define BUF_DI 0x01

// MAX7456 VIDEO_MODE_1 register

#define VIDEO_MODE_1_WRITE 0x01

#define VIDEO_MODE_1_READ 0x81

// MAX7456 DM_MODE register

#define DM_MODE_WRITE 0x04

#define DM_MODE_READ 0x84

// MAX7456 DM_ADDRH register

#define DM_ADDRH_WRITE 0x05

#define DM_ADDRH_READ 0x85

// MAX7456 DM_ADDRL register

#define DM_ADDRL_WRITE 0x06

#define DM_ADDRL_READ 0x87

// MAX7456 DM_CODE_IN register

#define DM_CODE_IN_WRITE 0x07

#define DM_CODE_IN_READ 0x87

// MAX7456 DM_CODE_OUT register

#define DM_CODE_OUT_READ 0xB0

// MAX7456 FM_MODE register

#define FM_MODE_WRITE 0x08

#define FM_MODE_READ 0x88

// MAX7456 FM_ADDRH register

#define FM_ADDRH_WRITE 0x09

#define FM_ADDRH_READ 0x89

// MAX7456 FM_ADDRL register

#define FM_ADDRL_WRITE 0x0A

#define FM_ADDRL_READ 0x8A

// MAX7456 FM_DATA_IN register

#define FM_DATA_IN_WRITE 0x0B

#define FM_DATA_IN_READ 0x8B

// MAX7456 FM_DATA_OUT register

#define FM_DATA_OUT_READ 0xC0

// MAX7456 STATUS register

#define STATUS_READ 0xA0

#define STATUS_40_RESET_BUSY 0x40

#define STATUS_20_NVRAM_BUSY 0x20

#define STATUS_04_LOSS_OF_SYNC 0x04

#define STATUS_02_PAL_DETECTED 0x02

#define STATUS_01_NTSC_DETECTED 0x01

// MAX7456 requires clearing OSD Black Level

// register bit 0x10 after reset

#define OSDBL_WR 0x6C

#define OSDBL_RD 0xEC

#define OSDBL_10_DisableAutoBlackLevel 0x10

结论和性能MAX7456评估板采用工作在20MHz时钟的MAXQ2000微控制器,该微控制器包含内部硬件SPI控制器。因此,MAX7456的SPI端口可以全速工作。上述软件SPI程序工作速度低于硬件控制器。不过针对客户缺少硬件SPI端口的工作环境,程序已优化至最简。SPI是Motorola, Inc.的商标。 |

电子发烧友App

电子发烧友App

评论