Tips Index

- Locate the power decoupling capacitor as close to the IC as possible.

- Where possible, use a ground plane.

- Use low-inductance capacitors for power-supply decoupling.

- Protective gels and coatings on the PRT element cause hysteresis.

- Protect the IC and PRT passivation layer during assembly.

- Keep the electrical wiring connection between the PRT element and the ASIC as short as possible.

- Buffer the power input with a low-impedance resistor and capacitor as close to the connector as possible.

- Don't intermingle PRT wiring traces with other circuit traces.

- Select the correct type of PRT die attach for the application.

- Place the ESD/EMI capacitors adjacent to the connector pins.

- Connect the circuit ground to the case with a resistive path to drain ESD charge.

- Tie unused IC inputs to VDD or GND, as appropriate, either directly or with a resistor.

- Minimize the number of wiring connections to the conditioning IC.

Locate the power decoupling capacitor as close to the IC as possible.

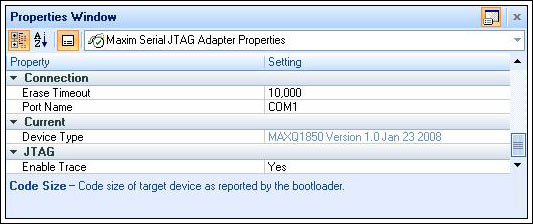

All conductors, even a straight copper PCB track, exhibit inductance effects at high frequencies. The greater the distance between an IC's power-supply pin and its associated decoupling capacitor, the greater this inductance will be. The high-frequency impedance produced by this inductance adds to other circuit-impedance elements and reduces the effectiveness of the power-supply decoupling, rendering the circuit more susceptible to high-frequency EMI and ESD effects. This inductance can be minimized by placing the power-supply decoupling capacitors as close as possible to the IC power-supply pins.Also see tips on using low-impedance capacitors and a ground plane.

Back to tips index

Where possible,use a ground plane.

A solid-copper plane presents the lowest impedance path. Using a ground plane to connect all ground points on a PCB is the best way to ensure that all circuit ground points are at the same potential. A ground plane also reduces the effect of radiated EMI on the performance of a circuit by reducing the electrical field strength in the vicinity of the ground plane. Electrical noise, together with EMI and ESD performance, can be significantly improved by the use of a ground plane.Back to tips index

Use low-inductance capacitors for power-supply decoupling.

Some capacitor types exhibit higher series inductance than others. Higher values of series inductance limit the effectiveness of capacitors when used at high frequencies by adding to the series impedance of these capacitors and lowering the circuit's tolerance to EMI and ESD effects. Ceramic surface-mount capacitors generally offer low series inductance values and should be used wherever possible. Electrolytic capacitors typically have high values of series inductance, and in circuits where they are required they should be bypassed by ceramic capacitors. The 0.1_F power-supply decoupling capacitors are specified for all Maxim sensor conditioner ICs; these should be surface-mount ceramic types.Back to tips index

Protective gels and coatings on the PRT element cause hysteresis.

Any material that contacts the diaphragm of a Piezo Resistive Transducer (PRT) can be detrimental to the performance of the sensor. Gels and protective coatings often produce hysteresis effects that cannot be corrected by sensor-conditioning techniques. The subsequent impact on sensor accuracy and repeatability can be quite substantial. If a protective coating or gel is to be used for media compatibility purposes, then it is important to understand the properties of the protective coating with respect to temperature (Tg, Tempco, creep, etc.), mixing ratio variances, aging, absorption, etc.Back to tips index

Protect the IC and PRT passivation layer during assembly.

An IC's passivation layer helps to protect the delicate silicon structures prior to packaging. This layer is in intimate contact with the surface of the IC and has little mechanical strength. Damage done to the IC as a result of physical contact with the passivation layer during handling or assembly may not be immediately apparent but could lead to device malfunction or failure at a later time. Any compromise of the IC passivation layer should be considered reason to scrap the assembly.Back to tips index

Keep the electrical wiring connection between the PRT element and the ASIC as short as possible.

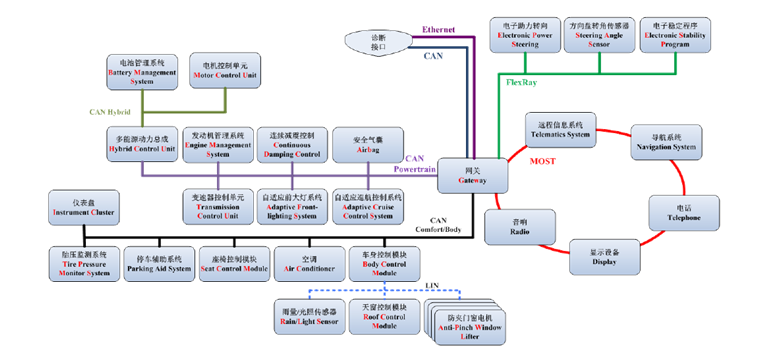

Long wires act as antennas that can pick up stray signals. They are one of the prime causes of mediocre sensor performance in the brutal automotive 2MHz-to-2GHz at-200-volts-per-meter EMI tests. The sensor should be mounted as close as possible to the conditioning IC.The use of a ground plane will help reduce noise. If a ground plane is not available, then try to run grounded PCB tracks as close as possible to the sensor connection tracks, particularly the connections to the conditioner inputs; see connections marked INP and INM on Maxim data sheets.

Back to tips index

Buffer the power input with a low-impedance resistor and capacitor as close to the connector as possible.

The resistance of a circuit to overvoltage transients and transmitted noise can be improved by the addition of a resistor and a capacitor in the power-supply line. This arrangement helps to filter out unwanted noise. A 10-ohm resistor and a 0.1_F capacitor will greatly reduce the effects of conducted EMI and potentially damaging overvoltage transients on the power-supply lines.Back to tips index Back to tips index Back to tips index Back to tips index Back to tips index Back to tips index Back to tips index

Select the correct type of PRT die attach for the application.

Use RTV for low-pressure (<100psi) rear-pressure designs and top-pressure designs; use epoxies for rear-pressure designs >100psi. Make sure you select fluoro-silicon RTV to prevent expansion from silicon oil absorption in oil-filled assemblies. Check the die attach for chemical compatibility with the sensed media.

Place the ESD/EMI capacitors adjacent to the connector pins.

Exposed connector pins present the most susceptible path for ESD strikes in a finished unit. The cable that connects with the unit can act as an antenna for picking up EMI. The conducted emissions that result from this are normally the largest of any EMI-induced effect. Minimize the effect of conducted ESD and EMI on the circuit by placing capacitors as close as possible to the connector. The capacitors should ideally be connected between the connector pins and the case. This ensures that the case and all electrical connections are, as far as possible, at the same electrical potential at higher frequencies. Be sure to use high-quality ceramic monolithic capacitors specified for use in ESD protection circuits.

Connect the circuit ground to the case with a resistive path to drain ESD charge.

Very high voltages can be generated on the ESD protection caps when the sensor is handled by the conductive case, with possible damage occurring when the connector is mated. Connect the circuit ground to the case with a resistive path to drain any accumulated charge. The value of this resistance is not critical. A few kilohms of resistance is fine for most applications.

Tie unused IC inputs to VDD or GND, as appropriate, either directly or with a resistor.

Undefined, floating inputs can cause havoc with an IC's internal operation. Stray EMI signals can couple to floating inputs and cause them to behave as if driven by a clock signal. Maxim ICs have integrated pullup or pulldown devices on digital inputs to help prevent these effects, but to be safe always tie unused inputs to a known potential such as VDD or GND.

Minimize the number of wiring connections to the conditioning IC.

All interconnect systems have a "per-pin" cost associated with them. The true cost of each wire connection encompasses not only the cost of the wire and termination but also of any additional features such as EMI or ESD protection devices. There are also per-pin costs associated with calibration and test fixtures. Reducing the number of wire connections to the conditioning IC reduces the per-pin costs. The MAX1452 and MAX1455 conditioner ICs allow the serial communications pin to be wired to the conditioner's output pin. This provides the facility to program the IC through the output connection, thus removing the need for a separate communications connection.

电子发烧友App

电子发烧友App

评论