Abstract: White light-emitting diode (WLED) drivers provide high efficiency and brightness matching for LCD backlighting in displays. To control brightness, these drivers regulate current going into LEDs that are arranged in either serial or parallel configuration. Charge pumps drive parallel LEDs whose currents are regulated with individual regulators or simple ballast resistors. Inductor-based converters deliver current to a string of LEDs, inherently equal. Both configurations aim to drive LEDs efficiently for cell phones, PDAs, and digital still cameras.

This application note describes how LEDs, including WLEDs, (WLEDs) work. The note also explains how to drive them in battery-powered LED applications, including lithium-ion (Li+ or Li-ion), nickel-cadmium (NiCd), and nickel metal-hydride (NiMH) rechargeable handheld devices where power consumption is important. LED brightness matching and the value of series vs. parallel LEDs are discussed. Application information is also presented for several LED drivers that can efficiently drive and control LEDs.

Figure 1. Relative spectral response of red, green, and yellow diodes (IF = 2mA, TA = +25°C).

Figure 2. Relative spectral response of white diodes (IF = 20mA, TA = +25°C).

In Figures 1 and 2, the curve Vλ represents the standard response of a human eye. To obtain white light, a blue emitter is covered with material that emits yellow light when stimulated by blue light. The eye interprets the output as white and creates the spectral response of Figure 2.

Figure 3. LED biasing with a single resistor per LED.

This design method offers low cost, but allows current variations due to the spread of VF values between each LED. Figures 4 and 5, which illustrate typical forward-voltage characteristics vs. forward current, show the variation at +25°C. At 20mA, the maximum values of VF rise to +2.7V for the GaAsP LED and up to +4.5V for the InGaN LED. For systems that require multiple diodes, such as a cell-phone display backlight (8 LEDs), the extra resistors occupy a considerable amount of printed circuit-board area.

Figure 4. Typical GaAsP forward voltage vs. forward current, at +25°C.

Figure 5. Typical InGaN forward voltage vs. forward current, at +25°C.

You can reduce the effect of VF variation by increasing the value of VSOURCE. That approach wastes power, however, and is incompatible with a low-voltage battery supply such as a single lithium-ion cell. The lithium-ion terminal voltage varies from +4.2V when fully charged to +3V when discharged. Consequently, an LED powered by this supply with simple resistor biasing will exhibit a noticeable variation in light output. Rather than resistor biasing, therefore, a better approach (for improving dropout and stabilizing the variation of light intensity with supply voltage) employs current biasing.

Figure 6. LED biasing with current sources.

The MAX1916 offers a simple approach to LED current biasing. Integrating three current sources in a small, 6-pin SOT23 surface-mount package (Figure 7), the MAX1916 implements the current-source approach of Figure 6. Current in the SET resistor is mirrored at the three OUT terminals. With current "mirrors," if the gate-source potentials for n identical MOS transistors are equal, their channel currents will also be equal. As a further advantage, if the mirrored MOS devices (Q2, Q3, and Q4) are m times bigger than the mirror MOS device (Q1), then the output current is m times greater than the mirror current (ISET).

An integrated circuit, finally, achieves more accurate current ratios than does a discrete circuit.

Figure 7. Simplified diagram of MAX1916 LED current mirrors.

Current mismatch between outputs in the MAX1916 is 5% maximum and the mirror constant is 230A/A ±10%. IOUT is given by:

IOUT = 230 ISET.

The SET terminal is internally biased to +1.215V ±5%, producing a SET current of:

ISET = (VSOURCE -1.215V)/RSET.

No LED current is more than 5% away from any other LED current. For example, if one LED current is 207 ISET (-10%), then the remaining LED currents must lie between 207 ISET and 218 ISET.

The output saturation voltage is nonlinear and cannot be modeled by a resistor. Representative maximum values over temperature are +0.410V at 20mA, +0.360V at 10mA, and +0.180V at 5mA.

Thus, a low-current GaAsP diode operating at 5mA requires a minimum voltage of VF + 180mV to function correctly, and LED operation can be maintained down to +2.9V. The low dropout value illustrates that the MAX1916 can remain in regulation down to very low drain-source voltages. To achieve a lower dropout voltage and higher output current, the MAX1916 outputs can be connected in parallel with a mirror constant of 690.

The voltage supply for the set current terminal may be derived separately from the main high-current supply. For a MAX1916 operating in a cellular radio, for example, VSET may be obtained from the RF circuit's low-noise, +2.8V power supply. When powered directly from a single lithium battery, the MAX1916 is suitable for operation with GaAsP low-forward-drop LEDs. A different approach is required for InGaN WLEDs powered from a lithium battery, because the input voltage may be insufficient to bias those LEDs.

The MAX1574/MAX1575/MAX1576 offer high output current, good current matching, adaptive mode switching for high efficiency, overvoltage protection, and up to 8 LED drive pins. Programmable dimming as a percentage of the set current is available through the DualMode™ enable pin using a serial-pulse code scheme.

Figure 8 shows a MAX1574 charge pump driving 3 LEDs at up to 180mA total output. The 1MHz switching rate allows use of small ceramic capacitors in the charge pump.

Figure 9 shows a MAX1576 charge pump driving two groups of 4 LEDs at up to 480mA total output. The flash group allows up to 100mA per LED; each group has independent set current, serial pulse dimming, and 2-wire log dimming controls. With adaptive mode switching, average efficiency is 83% over the discharge curve of a single lithium battery (Figure 10). The MAX1576 is ideal for digital still-camera applications using LED flash.

The MAX1575 is a part variation that drives two groups of LEDs (4 main LEDs and 2 sub-LEDs) at 120mA total output.

Figure 8. Integrated charge pump with one group of LED current sources.

Figure 9. Integrated charge pump with two groups of LED current sources.

Figure 10. MAX1576 efficiency at typical lithium-battery voltages.

Figure 11. Current regulation with the MAX1848 inductive boost converter drives up to 6 LEDs.

A number of inductive boost controllers, sized to match the number of series LEDs, are available. Up to 9 LEDs may be driven in series, thus removing the need for matching parallel strings. Table 1 shows the LX pin rating for each part. These parts feature overvoltage shutdown, so a guardband exists between the maximum rating of the LX pin and the maximum voltage of the series LED string.

Table 1. Part Selection vs. the Number of Series LEDs Driven

Figure 12. Current regulation with the MAX8595X inductive boost converter drives up to 9 LEDs.

A lower parts-count alternative to the MAX1848 is shown in Figure 12 using the MAX8595/MAX8596 high-voltage controllers. The MAX8595X can drive 9 LEDs at 25mA. The MAX8596X adds temperature derating so that the maximum LED current drops at temperatures above +42°C ambient. The MAX8596Z drives up to 8 LEDs.

The DualMode control pin allows logic-level PWM dimming using the capacitor on the comp pin as a filter. Frequencies from 200Hz to 200KHz may be used. Duty cycles from 0 to 100% produce output currents from 0 to full value. A simple, analog voltage level from a DAC may also be used. In this case, the output current-sense voltage is equal to 1/5 the control voltage up to the clamp voltage. The clamp voltage limits the LED current to full value, even if the control voltage increases above the limit.

The internal oscillator runs at 1MHz, allowing small components to be used. Efficiencies up to 86% are achievable. The MAX8596 offers the smallest package and lowest part count for the number of LEDs driven.

The MAX8790A is a high-efficiency, current-mode step-up driver for multiple parallel strings of WLED applications. MAX8790A can drive six parallel strings of multiple series-connected LEDs. It provides two dimming controls: analog dimming for higher converter efficiency, and digital dimming for less color distortion.

Figure 13. MAX8790A inductor boost converter drives up to six parallel chains of LEDs.

This application note describes how LEDs, including WLEDs, (WLEDs) work. The note also explains how to drive them in battery-powered LED applications, including lithium-ion (Li+ or Li-ion), nickel-cadmium (NiCd), and nickel metal-hydride (NiMH) rechargeable handheld devices where power consumption is important. LED brightness matching and the value of series vs. parallel LEDs are discussed. Application information is also presented for several LED drivers that can efficiently drive and control LEDs.

About LEDs

Light-emitting diodes (LEDs) are the solid-state, highly reliable, efficient counterparts of the evacuated tungsten-filament light bulb. Epitaxial material based on gallium arsenide phosphide (GaAsP) produces red, green, or yellow outputs (Figure 1). Material based on indium gallium nitrate (InGaN) produces blue or white outputs (Figure 2). Different chemistries also produce different electrical characteristics.

Figure 1. Relative spectral response of red, green, and yellow diodes (IF = 2mA, TA = +25°C).

Figure 2. Relative spectral response of white diodes (IF = 20mA, TA = +25°C).

In Figures 1 and 2, the curve Vλ represents the standard response of a human eye. To obtain white light, a blue emitter is covered with material that emits yellow light when stimulated by blue light. The eye interprets the output as white and creates the spectral response of Figure 2.

Biasing the Diodes

LEDs are current-driven devices in which the light output depends directly on the forward current passing through them. A simple biasing circuit that maintains the current (and consequently the light output) at a reasonably constant value, matches the intended power supply with a single current-limiting resistor connected in series with the LED (Figure 3).

Figure 3. LED biasing with a single resistor per LED.

This design method offers low cost, but allows current variations due to the spread of VF values between each LED. Figures 4 and 5, which illustrate typical forward-voltage characteristics vs. forward current, show the variation at +25°C. At 20mA, the maximum values of VF rise to +2.7V for the GaAsP LED and up to +4.5V for the InGaN LED. For systems that require multiple diodes, such as a cell-phone display backlight (8 LEDs), the extra resistors occupy a considerable amount of printed circuit-board area.

Figure 4. Typical GaAsP forward voltage vs. forward current, at +25°C.

Figure 5. Typical InGaN forward voltage vs. forward current, at +25°C.

You can reduce the effect of VF variation by increasing the value of VSOURCE. That approach wastes power, however, and is incompatible with a low-voltage battery supply such as a single lithium-ion cell. The lithium-ion terminal voltage varies from +4.2V when fully charged to +3V when discharged. Consequently, an LED powered by this supply with simple resistor biasing will exhibit a noticeable variation in light output. Rather than resistor biasing, therefore, a better approach (for improving dropout and stabilizing the variation of light intensity with supply voltage) employs current biasing.

Current Biasing

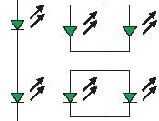

As the name of this technique suggests, the LEDs are connected to a current source. Assuming that the current source has an adequate dynamic range, this biasing method eliminates the effect of VF variations. Thus, individual current sources replace the individual resistors shown in Figure 5 (Figure 6). Assuming, therefore, a sufficient supply voltage to bias the current sources and LEDs, light output is independent of supply and forward voltages. As before, Q1 provides an enable switch.

Figure 6. LED biasing with current sources.

The MAX1916 offers a simple approach to LED current biasing. Integrating three current sources in a small, 6-pin SOT23 surface-mount package (Figure 7), the MAX1916 implements the current-source approach of Figure 6. Current in the SET resistor is mirrored at the three OUT terminals. With current "mirrors," if the gate-source potentials for n identical MOS transistors are equal, their channel currents will also be equal. As a further advantage, if the mirrored MOS devices (Q2, Q3, and Q4) are m times bigger than the mirror MOS device (Q1), then the output current is m times greater than the mirror current (ISET).

An integrated circuit, finally, achieves more accurate current ratios than does a discrete circuit.

Figure 7. Simplified diagram of MAX1916 LED current mirrors.

Current mismatch between outputs in the MAX1916 is 5% maximum and the mirror constant is 230A/A ±10%. IOUT is given by:

IOUT = 230 ISET.

The SET terminal is internally biased to +1.215V ±5%, producing a SET current of:

ISET = (VSOURCE -1.215V)/RSET.

No LED current is more than 5% away from any other LED current. For example, if one LED current is 207 ISET (-10%), then the remaining LED currents must lie between 207 ISET and 218 ISET.

The output saturation voltage is nonlinear and cannot be modeled by a resistor. Representative maximum values over temperature are +0.410V at 20mA, +0.360V at 10mA, and +0.180V at 5mA.

Thus, a low-current GaAsP diode operating at 5mA requires a minimum voltage of VF + 180mV to function correctly, and LED operation can be maintained down to +2.9V. The low dropout value illustrates that the MAX1916 can remain in regulation down to very low drain-source voltages. To achieve a lower dropout voltage and higher output current, the MAX1916 outputs can be connected in parallel with a mirror constant of 690.

The voltage supply for the set current terminal may be derived separately from the main high-current supply. For a MAX1916 operating in a cellular radio, for example, VSET may be obtained from the RF circuit's low-noise, +2.8V power supply. When powered directly from a single lithium battery, the MAX1916 is suitable for operation with GaAsP low-forward-drop LEDs. A different approach is required for InGaN WLEDs powered from a lithium battery, because the input voltage may be insufficient to bias those LEDs.

Inductor-Free Boosted Supply for WLEDs

A boosted supply is required for WLED applications, because the forward voltage (+3.5V to +4.5V at 20mA) is higher for a WLED than for other LED types. In the past, a charge-pump boost supply was paired with a MAX1916 to solve this problem. These functions, however, have been combined in the MAX1574/MAX1575/MAX1576 controllers, thus requiring less space at a lower cost.The MAX1574/MAX1575/MAX1576 offer high output current, good current matching, adaptive mode switching for high efficiency, overvoltage protection, and up to 8 LED drive pins. Programmable dimming as a percentage of the set current is available through the DualMode™ enable pin using a serial-pulse code scheme.

Figure 8 shows a MAX1574 charge pump driving 3 LEDs at up to 180mA total output. The 1MHz switching rate allows use of small ceramic capacitors in the charge pump.

Figure 9 shows a MAX1576 charge pump driving two groups of 4 LEDs at up to 480mA total output. The flash group allows up to 100mA per LED; each group has independent set current, serial pulse dimming, and 2-wire log dimming controls. With adaptive mode switching, average efficiency is 83% over the discharge curve of a single lithium battery (Figure 10). The MAX1576 is ideal for digital still-camera applications using LED flash.

The MAX1575 is a part variation that drives two groups of LEDs (4 main LEDs and 2 sub-LEDs) at 120mA total output.

Figure 8. Integrated charge pump with one group of LED current sources.

Figure 9. Integrated charge pump with two groups of LED current sources.

Figure 10. MAX1576 efficiency at typical lithium-battery voltages.

Inductor-Based WLED Controller

Combining a boost converter and current sense in an 8-pin SOT23 package, the MAX1848 can drive as many as two strings of 3 WLEDs from an input supply in the +2.6V to +5.5V range (Figure 11). The MAX1848 employs voltage feedback to regulate current into the LEDs. Analog control sets the overall LED brightness; a DAC or voltage-divider driving the DualMode control pin sets the LED current. The voltage control range for the circuit shown is +250mV to +3.3V for an LED current range of less than 2mA to 20mA per string (0V for shutdown). With parallel strings, however, brightness matching between strings can be a problem, so additional series resistance is added at the expense of efficiency. A good compromise is to add 20Ω per LED or 60Ω total for 3 LEDs.

Figure 11. Current regulation with the MAX1848 inductive boost converter drives up to 6 LEDs.

A number of inductive boost controllers, sized to match the number of series LEDs, are available. Up to 9 LEDs may be driven in series, thus removing the need for matching parallel strings. Table 1 shows the LX pin rating for each part. These parts feature overvoltage shutdown, so a guardband exists between the maximum rating of the LX pin and the maximum voltage of the series LED string.

Table 1. Part Selection vs. the Number of Series LEDs Driven

| Part | LX Pin Rating (V) | # Series LEDs | Package |

| MAX1848 | 14 | 3 | 8-SOT23 |

| MAX1561/MAX1599 | 30 | 6 | 8-TDFN |

| MAX8595Z/MAX8596Z | 37 | 8 | 8-TDFN |

| MAX8595X/MAX8596X | 40 | 9 | 8-TDFN |

Figure 12. Current regulation with the MAX8595X inductive boost converter drives up to 9 LEDs.

A lower parts-count alternative to the MAX1848 is shown in Figure 12 using the MAX8595/MAX8596 high-voltage controllers. The MAX8595X can drive 9 LEDs at 25mA. The MAX8596X adds temperature derating so that the maximum LED current drops at temperatures above +42°C ambient. The MAX8596Z drives up to 8 LEDs.

The DualMode control pin allows logic-level PWM dimming using the capacitor on the comp pin as a filter. Frequencies from 200Hz to 200KHz may be used. Duty cycles from 0 to 100% produce output currents from 0 to full value. A simple, analog voltage level from a DAC may also be used. In this case, the output current-sense voltage is equal to 1/5 the control voltage up to the clamp voltage. The clamp voltage limits the LED current to full value, even if the control voltage increases above the limit.

The internal oscillator runs at 1MHz, allowing small components to be used. Efficiencies up to 86% are achievable. The MAX8596 offers the smallest package and lowest part count for the number of LEDs driven.

The MAX8790A is a high-efficiency, current-mode step-up driver for multiple parallel strings of WLED applications. MAX8790A can drive six parallel strings of multiple series-connected LEDs. It provides two dimming controls: analog dimming for higher converter efficiency, and digital dimming for less color distortion.

Figure 13. MAX8790A inductor boost converter drives up to six parallel chains of LEDs.

电子发烧友App

电子发烧友App

评论