The input board is a small PCB mounted directly on the connector.

The main CPU board is mounted directly on the display.

Updated 3. Sep. 2002.

If you are from Denmark ! read the Danish version !!

In the good old days I had some parts but now

This Wattmeter is in ELEKTOR MAGAZINE OKTOBER 2002, they will sell PIC and PCB

The extra input B is for a later SWR brigde project, also the TX serial output will be in use later.

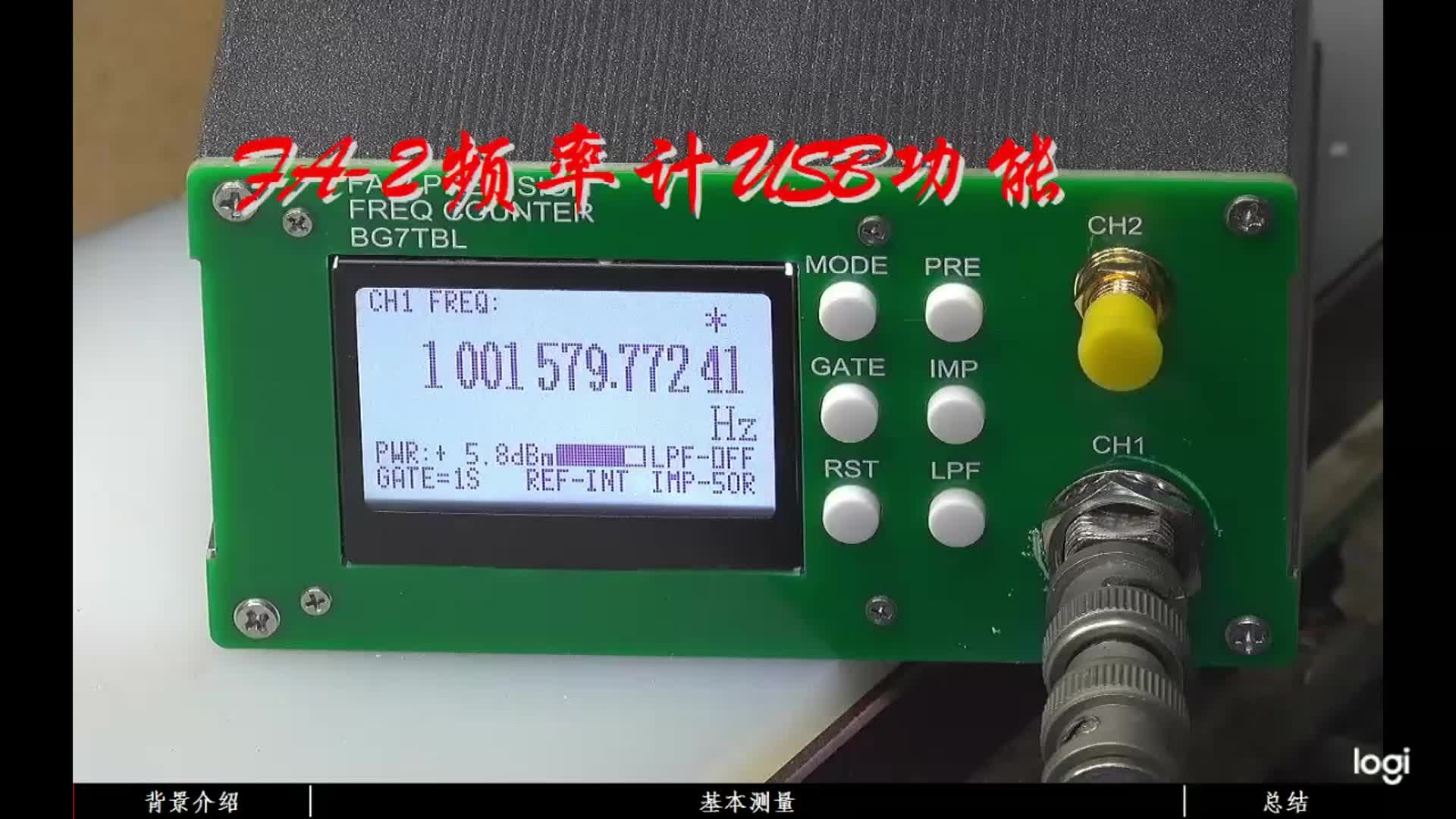

The uncalibrated signal response is: +1/-1 dB from 1MHz to 450MHz.

Input SWR vill varry from 1.00 to 1.30, depending on input frequency.

To make the SWR this good, you need to assemble the input circuit correct and adjust the capasitor.

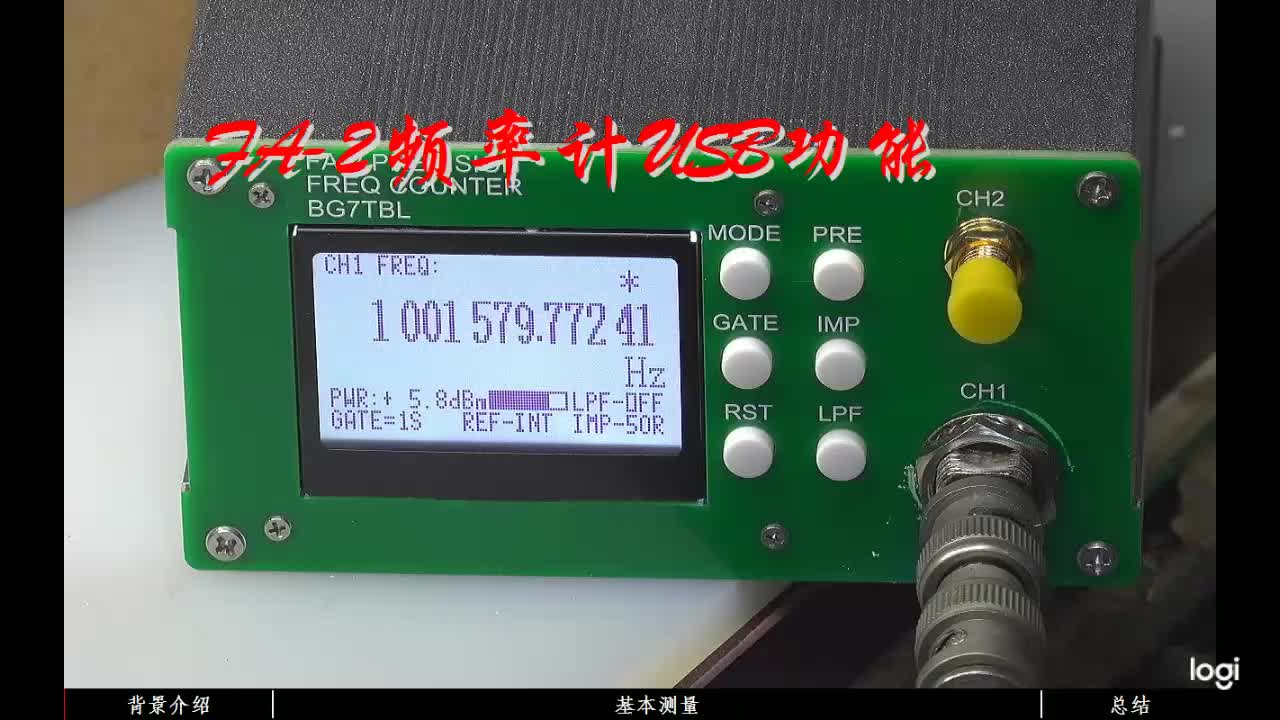

Input power range: -60 to +30dBm that is 1 nW to 1 Watt.

This instrument can be used and calibrated from 1 kHz and up to 500 MHz

It is possible to measure power relative all the way up to 900Mhz

A software routine can calibrate the 0dBm point at 5 different frequencies to make this instrument accurate within 0.5dBm !!

The calibration data is stored in EEPROM so the instrument will remember all, also without power.

At frequencies above 300Mhz this instrument should not exceed inputs over +20dBm (100mW) to keep the good accuacy

This is a documented weekness in the AD8307, this is not a big problem, if you are aware of this, then it's just a matter of using the right input attenuator

If battery opperation: do not connect R30, also change R26 and R27 to 4k7

Ideas taken from articles in: QST June 2001 page 38 and Funkamateur 12/99 page 1383 And Elektor 1/99 page 26

The display, shows dBm from -60 to +30dBm, RF Voltage and RF Power and Bargraph in 1db step.

The backlite is verry powerfull, I had to change R30 to 10E

Also I must complement the POWERTIP display for it's exelent contrast and viewing angle and low prize !

I use a POWERTIP display with 20 caracters in 2 lines with LED light.

Powersupply current is:

With no light: = 30 mA. (R30 = NC)

Normal light: = 120 mA. (R30 = 10E)

Power light: = 200 mA. (R30 = 4E7)

Here is main PCB assembled, ready to be mounted on the display.

The cabinet is homemade of glasfiber PCB, easy and cheap to construct.

There is made plenty of room for a batterypack, and also I like it not to be too small

so that it's hard to come in and make modifications.

Here a view of the back side of the switches and the rotary encoder

note the RF filter on the DC voltage input.

The backside powersupply input, and powersupply selector switch

The DC voltmeter switch is connected so that it's only possible to measure the battery voltage when it's running on battery.

Here is how I have connected the two switches, the charge resistor and diode needs to be adjusted to fit the used battery.

If no battery supply is needed, only one switch is then mounted.

Also the powersupply cords can transfer unwanted RF noice, so here is also added a RF blocking filter

Note the diode and little-fuse for reverse polarity protection.

The NEW version of the PCB Now the input coil has been removed

The AD8307 is SMD SO-8, the extra input board is for a later project (SWR bridge), more about this next year.

The TX serial out pin is for several future projects, that uses a PC to draw curves and more.

The bottom PCB side is mostly shilding PCB size is 79mm wide and 37mm height

Here is all the measurements curves

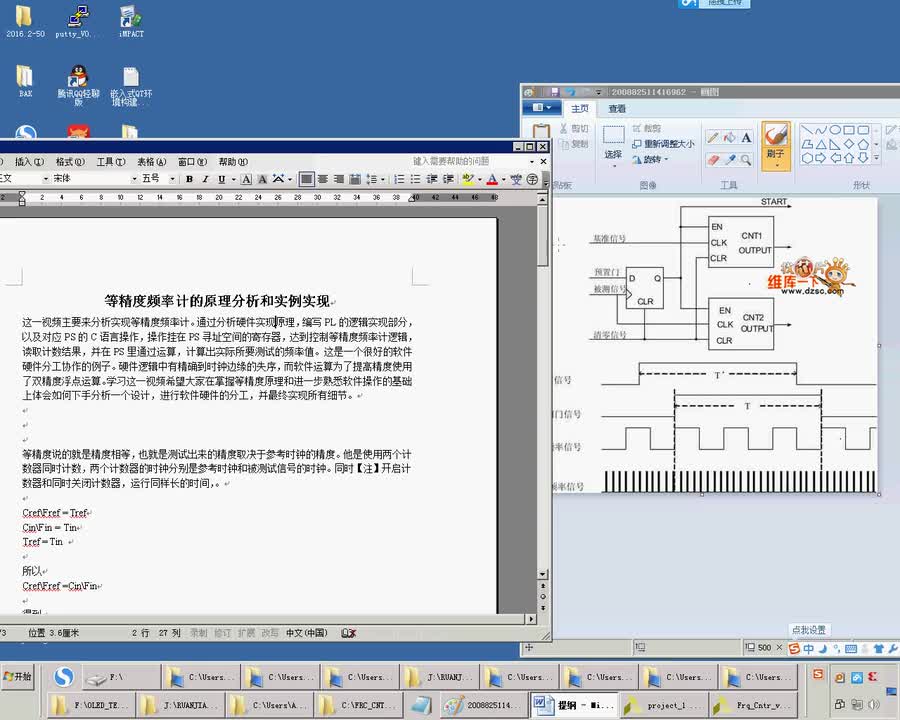

Software information users guide and download

PC logger software for windows

Complete part list

Assembly and solder instructions

Digital Wattmeter construction-competition

Serial output format and hardware sorry this page only in Danish

Front plate and box design Here is my sugestion about how to do it

Comments, Ideas, News from all of us to all of you

Output to freq counter and DFD4 counter modifications

F6GOG Wattmeter page A must see page !!

How To Measure High Power

The digital-powermeter input range is 1nW to 1W.To measure more power an attenuator can be mounted in front of it, but they are expensive !

A good and cheap solution is to use a -40 dB tab.

The Wattmeter readout can be set to show correct values, using five standard attenuators,

Attenuator settings: none, -10, -20, -30, -40 and -50dB, by this it is now possible to measure from 1nW up to 100 kW

Here is my simple homemade -40dB tap, using 3 BNC connectors a small cheap box and a few resistors.

The four first resistors is 620 Ohm each the bottom resistors is two 100 Ohm in parallel.

This uncompensated circuit can be used up to 170 Mhz and up to 50 Watts continius

This is a much better solution, but also a bit harder to make

This -40dB tab has good SWR up to 900 MHz, and the -40dB output signal has a perfect flat response up to 600Mhz

The 2.7mm stripline needs to be verry acurate, the PCB is double sided 1.6mm thick.

note that the stripline goes all the way as close as possible to the connector isolation

Here is a closeup, note the tab compensation wire, that is adjusted close to the two first resistors,

by this way it is possible to adjust a perfect flat -40 dB response up to 600 MHz

This tab can also only handle 50 Watts, limited by the four 1/4 watt resistors

To get -40dB a 100:1 voltage divider is made with 50 Ohm output impedance, so when this output is loaded

the total load resistance is 25 Ohm, now that we have the output bottom resistance of 25 Ohm we can calculate

the total resistance of the 100:1 voltage divider, 100 * 25 = 2500 Ohm so the top resistance is 2500 - 25 = 2475 Ohm

if four resistors is used they shuld be 2475 / 4 = 618.75 Ohm so I use 620 Ohm that is a standard

Power in the resistors: I use 250 mW resistors * 4 = 1 Watt the power in the bottom resistors is negible..

To calgulate the MAX RF power level, U = square root P * R, it was 1W and 2500 Ohm this give 50 Volt, this is equal to 50 W

the resistors can stand the double power for about 1 minute and 4 times a few sec, so to my needs this is fine

a 30dB attenuator

Ready made attenuator modules is made by several companies. Here is a 30 dB 100Watt from RF Power

Their web site www.rf-power.com

In this case it can not with stand 100 Watt so long, due to the lack of heat sink

The 30 dB attenuation is verry acurate from 0 to 500 Mhz, it has also perfect return loss

I know a nice person that have access to a CNC machine, he made this alu box for me.[---分页---]

Front Plate and case creation

The front plate, width = 204 mm Hight = 54 mm

I have made this front plate design with my PCB program

Then it is easy to make the rest few plates and solder them to a box.

After that, paint it black or what ever collor you like.

Here is the front plate PCB just arrived from the PCB manufacture

The rear side is cobber, so that it is easy to solder the walls to it.

Here is all the PCB parts before soldering.

The depth of 40 mm is the minimum size, now there is no room for batteries or RS-232

All measurements in millimeters as usual.

Here is the M3 nut, before it is soldered to the mounting plate.

Case is now almost ready for painting.

Seen from front, just before painting.

When it is painted, the text can be added, use SENO or LETRA-SET,

Then a transparent paint is sprayed on to secure the text.

Here the unit finished !

- 组图功率(5682)

相关推荐

电子发烧友App

电子发烧友App

评论