Abstract: Measurement of micro-fluidic flow for biochemical and medical purposes is demonstrated with a micro-electromechanical system and two pressure sensor compensating integrated circuits (ICs). The flow rate of a fluid can be determined by the pressure drop across a precision machined channel. The entire assembly fits on a small ceramic hybrid assembly.

Fluid analysis is essential in a wide range of current applications. Biology, medical analysis, genetic engineering, and many other fields rely on fast, precise, and reproducible chemical and biological analyses. Tools that automate the dosing and analysis of fluid samples are essential for affordable performance.

Highly specialized electronic sensors have been designed to automate sample analysis, but the dosing of liquids – still a prominent issue – must be done physically. This operation is usually accomplished with specialized micro-syringes driven by stepper motors. It's easy to imagine the difficulty and expense associated with such setups.

In a novel approach to this problem, DASA IMT and Seyonic SA (both of Neuchâtel, Switzerland) developed flow-through micro-fluidic dosing as part of a toolkit for experiments performed in space. As described in the following, a key element of that design was a micro-flow sensor device. Requirements were:

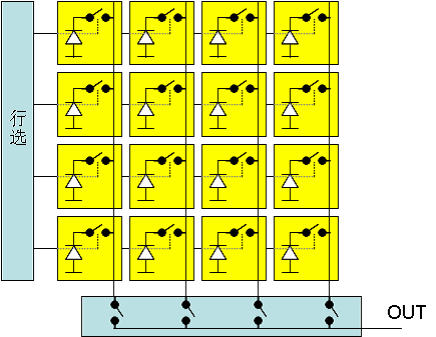

To insure that the sensor is not affected or altered by chemically aggressive fluids, the fluid under pressure is applied to the back of the sensor diaphragm (whose monocrystal-line silicon is relatively insensitive to the chemicals) rather than the front. This unusual configuration protects sensitive microelectronic circuits on top of the sensor by shielding them from the liquid. To prevent error from mechanical-tension forces, the sensor is mounted on a thick ceramic substrate (Figure 1).

Figure 1. This cross section shows the dual piezo-resistive pressure sensors mounted on a thick ceramic substrate.

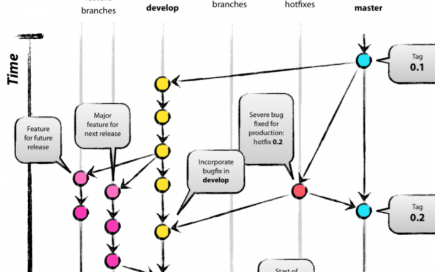

Piezo-resistive pressure sensors exhibit excellent sensitivity and reproducibility, but they are quite sensitive to changes in environmental temperature. Until recently, there was no way to compensate these errors while achieving the small size and fast response needed in micro-fluidic flow sensing. One solution to this problem is the new MAX1458 sensor-signal processor, which compensates piezo-resistive sensors for initial and temperature-dependent errors. Figure 2 compares the output of an uncorrected sensor with the same output compensated with this IC.

Figure 2. This before-and-after comparison shows the reduction in sensor error achieved with the MAX1458 sensor-signal conditioner.

Digital and user-programmable registers perform a fully electronic compensation of the analog signal path. For applications exposed to large environmental temperature changes such as the -40°C to +125°C automotive range, the MAX1458 delivers a total output accuracy better than 1%. For a more limited span such as +15°C to +45°C, the total pressure accuracy approaches 0.1%.

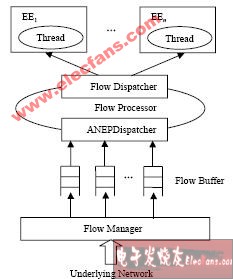

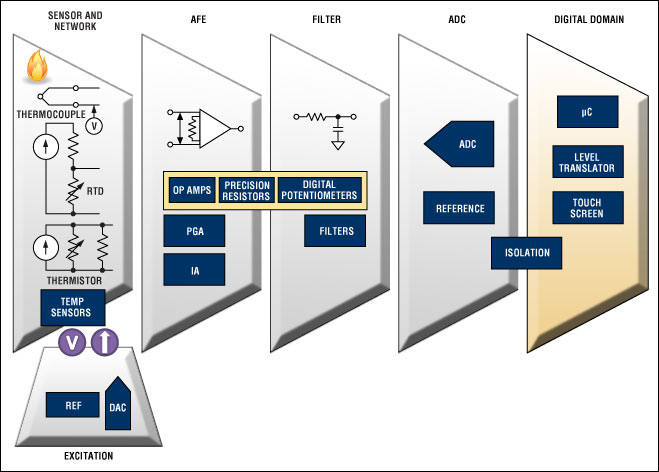

A block diagram illustrates the IC's internal structure (Figure 3a and 3b). A patented sensor-bridge excitation circuit counteracts any decrease in sensitivity by causing the bridge-drive voltage to rise with temperature. The compensated sensor bridge also acts as a temperature sensor, and is sufficiently linear to serve for correcting offset drift vs. temperature.

Figure 3a. Patented sensor-bridge excitation circuit.

Figure 3b. A differential analog-output path.

The output signal is adjustable between 0.5V and 4.5V (when operating with 5V supplies), and it accommodates sensor sensitivities of 10mV/V and higher. All coefficients required for compensation are held in an EEPROM internal to the MAX1458. Thus, the setup is easily and automatically calibrated via a simple 4-wire serial interface.

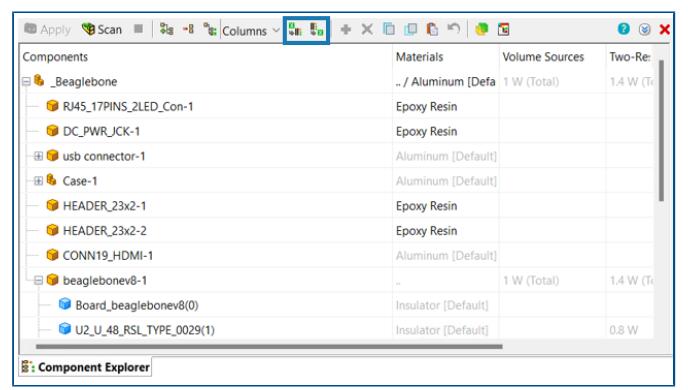

Because the relationship between measured differential pressure and liquid flow rate depends on the liquid's viscosity, which in turn changes with temperature, the MAX1458 provides a temperature output signal for use in external signal processing. This setup (Figure 4) allows the measurement of flow rates no higher than 5.5µl/sec. The analog pressure signals, the temperature sensor terminals, and all other connections are made accessible at a connector for external post?processing.

Figure 4. The pressure-sensor module consists of a dual flow sensor and two signal-conditioner ICs.

A photo of the 12x19mm pressure-sensing module (Figure 5) illustrates the MCM technology: a monolithic flow sensor module, wire-bonded to the ceramic carrier, connects to the two sensor-signal processors (MAX1458s), which are also wire-bonded and mounted as dice. Figure 6 illustrates a micro-fluidic dosing and analysis system, in which the flow-sensor output described above serves as a feedback signal in achieving continuous and dynamic flow-rate control.

Figure 5. Built with multi-chip-module (MCM) technology, the pressure-sensor module measures 12x19mm.

Figure 6. In this micro-fluidic dosing and analysis system, the flow-sensor output provides feedback for continuous flow-rate control.

Authors:

Bernhard Konrad, Maxim Integrated Products, Germany

Philipp Arquint, Institute of Microtechnology, University of Neuchâtel

Bart van der Schoot, Seyonic SA, Neuchâtel

Fluid analysis is essential in a wide range of current applications. Biology, medical analysis, genetic engineering, and many other fields rely on fast, precise, and reproducible chemical and biological analyses. Tools that automate the dosing and analysis of fluid samples are essential for affordable performance.

Highly specialized electronic sensors have been designed to automate sample analysis, but the dosing of liquids – still a prominent issue – must be done physically. This operation is usually accomplished with specialized micro-syringes driven by stepper motors. It's easy to imagine the difficulty and expense associated with such setups.

In a novel approach to this problem, DASA IMT and Seyonic SA (both of Neuchâtel, Switzerland) developed flow-through micro-fluidic dosing as part of a toolkit for experiments performed in space. As described in the following, a key element of that design was a micro-flow sensor device. Requirements were:

- Small size

- Chemical inertia

- Temperature stability

- Long-term stability

- Simple, easy, and fully automated recalibration

- Linear voltage-versus-pressure output

To insure that the sensor is not affected or altered by chemically aggressive fluids, the fluid under pressure is applied to the back of the sensor diaphragm (whose monocrystal-line silicon is relatively insensitive to the chemicals) rather than the front. This unusual configuration protects sensitive microelectronic circuits on top of the sensor by shielding them from the liquid. To prevent error from mechanical-tension forces, the sensor is mounted on a thick ceramic substrate (Figure 1).

Figure 1. This cross section shows the dual piezo-resistive pressure sensors mounted on a thick ceramic substrate.

Piezo-resistive pressure sensors exhibit excellent sensitivity and reproducibility, but they are quite sensitive to changes in environmental temperature. Until recently, there was no way to compensate these errors while achieving the small size and fast response needed in micro-fluidic flow sensing. One solution to this problem is the new MAX1458 sensor-signal processor, which compensates piezo-resistive sensors for initial and temperature-dependent errors. Figure 2 compares the output of an uncorrected sensor with the same output compensated with this IC.

Figure 2. This before-and-after comparison shows the reduction in sensor error achieved with the MAX1458 sensor-signal conditioner.

Digital and user-programmable registers perform a fully electronic compensation of the analog signal path. For applications exposed to large environmental temperature changes such as the -40°C to +125°C automotive range, the MAX1458 delivers a total output accuracy better than 1%. For a more limited span such as +15°C to +45°C, the total pressure accuracy approaches 0.1%.

A block diagram illustrates the IC's internal structure (Figure 3a and 3b). A patented sensor-bridge excitation circuit counteracts any decrease in sensitivity by causing the bridge-drive voltage to rise with temperature. The compensated sensor bridge also acts as a temperature sensor, and is sufficiently linear to serve for correcting offset drift vs. temperature.

Figure 3a. Patented sensor-bridge excitation circuit.

Figure 3b. A differential analog-output path.

The output signal is adjustable between 0.5V and 4.5V (when operating with 5V supplies), and it accommodates sensor sensitivities of 10mV/V and higher. All coefficients required for compensation are held in an EEPROM internal to the MAX1458. Thus, the setup is easily and automatically calibrated via a simple 4-wire serial interface.

Because the relationship between measured differential pressure and liquid flow rate depends on the liquid's viscosity, which in turn changes with temperature, the MAX1458 provides a temperature output signal for use in external signal processing. This setup (Figure 4) allows the measurement of flow rates no higher than 5.5µl/sec. The analog pressure signals, the temperature sensor terminals, and all other connections are made accessible at a connector for external post?processing.

Figure 4. The pressure-sensor module consists of a dual flow sensor and two signal-conditioner ICs.

A photo of the 12x19mm pressure-sensing module (Figure 5) illustrates the MCM technology: a monolithic flow sensor module, wire-bonded to the ceramic carrier, connects to the two sensor-signal processors (MAX1458s), which are also wire-bonded and mounted as dice. Figure 6 illustrates a micro-fluidic dosing and analysis system, in which the flow-sensor output described above serves as a feedback signal in achieving continuous and dynamic flow-rate control.

Figure 5. Built with multi-chip-module (MCM) technology, the pressure-sensor module measures 12x19mm.

Figure 6. In this micro-fluidic dosing and analysis system, the flow-sensor output provides feedback for continuous flow-rate control.

Authors:

Bernhard Konrad, Maxim Integrated Products, Germany

Philipp Arquint, Institute of Microtechnology, University of Neuchâtel

Bart van der Schoot, Seyonic SA, Neuchâtel

电子发烧友App

电子发烧友App

评论