Abstract: RS-485 transceivers offer an easy way to implement the physical layer in industrial networks; several fieldbus standards specify an RS-485 serial port for communications. This article describes several fieldbus technologies, and highlights some particularly useful features of the available RS-485 transceivers.

Because RS-485 transceivers offer an easy way to implement the physical layer in industrial networks, several fieldbus standards specify an RS-485 serial port for communications. This article describes several fieldbus technologies, and highlights some particularly useful features of the available RS-485 transceivers.

Extensive data systems are employed in industrial plants to measure, collect, transmit, and display information. Valves must be controlled while temperature and pressure are measured, displayed, and fed to the process-control system. To connect the controller unit with sensors and actuators, many process and manufacturing facilities still include field multiplexers or multi-wire connections (based on 4mA–20mA loops or 0–10V circuits). Because the wiring required in those older systems is enormous, modern plants often save wiring effort by employing a serial, real-time, data-link industrial network (fieldbus system) for process and manufacturing control.

Fieldbus systems are similar to the widespread Ethernet office networks, in that a single bus connects all devices on one network to a central controller. Not only does that arrangement require substantially less wire, it also increases the system modularity. All devices are addressed via software, so any device can be connected to any socket along the network. The master detects which device is connected to the network, and initiates the action required to start communications.

A fieldbus provides other advantages over Ethernet, which may explain why Ethernet has not yet run the last mile in connecting PLCs and industrial PCs to field sensors and actuators. One fieldbus advantage is determinism, meaning that signals are received in real time, and the recipient immediately provides an acknowledging signal. Determinism is obviously required for an alarm signal that must be distributed in real time.

Fieldbus networks are also robust. Industrial networks must often guarantee gas-tight connectors and operate over the industrial temperature range of -45°C to +85°C (most Ethernet controller ICs are specified only for 0–70°C operation). It is possible to create an industrial Ethernet system that includes the additional protocol software for determinism, robust connectors, and industrial-temperature-range controller ICs, but such networks are more expensive. They also incur additional cost in compensating for high protocol overhead, which requires a higher data rate than that of a regular fieldbus.

Attached Resource Computer Network (ARCNET): provides data rates up to 10Mbps. Started by SMC/Datapoint (USA) in 1977, it began as an office network and now serves industrial plants as well. Very flexible.

Bitbus: up to 375kbps; started by Intel (USA) in 1984. Used mainly for communication between programmable logic controllers (PLCs) and the main controller in manufacturing applications.

European Installation Bus (EIB): up to 9600bps; started in 1989 (Germany). Used in building automation.

Flux Information Processbus (WorldFip): up to 2.5Mbps (typically 1Mbps); started in 1984 (France). Mainly for industrial process automation in France and Italy.

Local Operating Network (LON): up to 1.25Mbps; started by Echelon Inc. (USA) in 1990. Used mainly for building automation.

Process Field Bus with decentralized peripherals (PROFIBUS DP): up to 12Mbps; started by PNO (Germany) in 1993. Used mainly in manufacturing automation.

INTERBUS: up to 2Mbps (typically 500kbps); started by Phoenix Contact (Germany) in 1987. Used mainly in manufacturing automation.

Other standards (such as CAN) have a different physical interface, but we will consider only the RS-485 PROFIBUS DP and Interbus. They have the largest market share and the highest growth rate in industrial RS-485 networks. For additional information about fieldbus standards, see http://www.fieldbusworld.com.

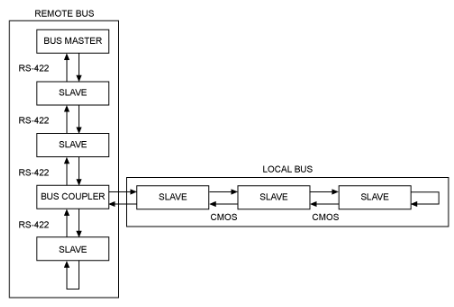

The backbone of an INTERBUS is the remote bus, headed by a bus master that controls data communications. Each remote bus device (slave) is connected to the follow-on device via full-duplex, RS-422 point-to-point connections as shown in Figure 1. A maximum bus length of 400m is allowed between any two slaves, and the total bus length is limited to 13km. Each slave connects to the bus via two full-duplex RS-422 transceivers, one on each side of the slave. Those connections provide a repeater function that ensures good transmission quality over the entire network.

Figure 1. An INTERBUS network can include local- and remote-bus data loops, all operating in the 4-wire, full-duplex communication mode. Multiple local-bus loops are allowed.

No more than 512 slaves may be connected to one master, and each slave has its own power supply. A slave may also function as a bus-coupler (a bus-interface module) that feeds a local bus of up to eight devices. The local bus is limited to 10m (10 meters) in overall length and to 1.5m between any two devices. Local bus communication is implemented over pairs of 2-wire cables, using full-duplex CMOS-level signals rather than the standard RS-422-level signals.

The INTERBUS standard requires that components in a network be certified by an accredited test laboratory. Any PCB designer may apply for such a certificate at the local INTERBUS clubae representing an international association of companies whose common goal is to push (INTERBUS applications).

Figure 2. Typical RS-422 transceiver in an INTERBUS remote bus.

Supply current is important in minimizing power dissipation. The housing of a fieldbus device may be quite small, and therefore difficult to provide with an effective heatsink. Moreover, many applications require a galvanically isolated bus, so power must be distributed to the RS-485 transceiver across an isolation barrier.

The MAX3087E also provides ±15kV of ESD protection. A technician can destroy valuable unprotected electronic devices just by touching them, and that static discharge can occur with a single contact during installation of the fieldbus cable. The ESD structures included in Maxim ICs protect both the transmitter outputs and receiver inputs of multiple interface circuits against electrostatic discharge. During manufacture, the ICs' positive and negative rails are tested in 200V increments according to the Human Body Model (IEC Standard 1000-4-2). Thus, unlike competitive parts that may withstand 15kV strikes but fail at 6kV, the Maxim parts guarantee protection against the smaller ESD strikes as well.

Figure 3. The PROFIBUS network is laid out in a single line. Up to five bus segments are allowed, each containing up to 32 nodes. A Mono Master System is shown with a single master per segment.

PROFIBUS DP connects to the bus using half-duplex RS-485 transceivers, which transfer data over a single, shielded, twisted-pair cable. PROFIBUS also allows the possibility of an optical connection using plastic fiber. Other family members are PROFIBUS FMS, an older version for the process-management level that has been mostly replaced by Ethernet, and PROFIBUS PA, an intrinsically safe version for process-control applications.

PROFIBUS DP allows up to 32 nodes per bus segment, including masters, slaves, and any repeaters. You can add bus segments up to a total of five, with each segment isolated by a repeater. The bus size may be extended in this way to an overall total of 126 nodes. PROFIBUS DP has a high overhead for protocol, because various diagnostic functions are added to the actual message to guarantee safe data transmission.

Communications are controlled by one or more Class-1 masters. The system also includes Class-2 masters, which compose the human-machine interface used to program devices and operate systems on the bus. A slave can be a sensor, an actuator such as a magnetic valve, or a decentralized digital or analog input or output. The PROFIBUS standard requires that all end equipment connected to a PROFIBUS be certified by an accredited test lab (see http://www.profibus.com).

Figure 4. Typical RS-485 transceiver for PROFIBUS DP.

Maxim's true failsafe feature, implemented in MAX3463/MAX3464 devices, avoids external biasing resistors by substituting a precise receiver-threshold range (-50mV to -200mV) that complies fully with RS-485 specifications while guaranteeing that a 0V input produces a logic "High" at the receiver. The remaining termination resistor (approximately 200Ω) is connected between the differential lines. By eliminating the 330Ω pullup and pulldown resistors otherwise needed, that connection saves additional power.

The capability of a standard RS-485 driver to drive up to 32 unit loads sets the 32-node maximum for a PROFIBUS DP bus segment. One unit load is defined as 12kΩ, which corresponds to the input impedance for a standard RS-485 receiver. The higher input impedance of MAX3463/MAX3464 receivers (48kΩ, which is 1/4 unit load) allows 128 transceivers on the bus. Any combination of RS-485 transceivers can connect to one bus segment, provided the net parallel impedance of those circuits remains above 375Ω (32 unit loads).

Conceivably, the PROFIBUS DP size could be increased to 128 nodes per segment, for a total of 640 nodes in five segments. The MAX3463 includes another useful feature. When bus nodes are powered up or plugged into a "hot" backplane, there follows a short interval in which the processor or control ASIC executes its power-up sequence. The processor's output drivers are in a high-impedance state during that time, and are therefore unable to drive the RS-485 transceiver's control lines (active-low RE, DE, DI) to defined logic levels.

Leakage current from those high impedance drivers (as much as 10µA) can cause the RS-485 circuits control lines to drift high or low. In addition, parasitic capacitance on the circuit board can couple the control lines to either GND or VCC. These factors cause the control lines to drift toward levels that may enable the circuit's transmitters (A and B). To avoid that condition, the MAX3463 includes hot-swappable inputs that disable the MAX3463 control lines as VCC ramps up from 0V. Hot-swap inputs overcome the leakage currents and parasitic capacitances that might otherwise pull the control lines to the enabled state. Full-duplex versions (MAX3460-MAX3462) are available for high-speed RS-422 applications.

Because fieldbus systems can include a large number of RS-485 or RS-422 drivers, power delivered to the drivers can represent a significant part of the system cost. That is particularly true when supplying the power across an isolation barrier. Because legacy RS-485/RS-422 drivers require considerable supply current (as much as 30mA quiescent, plus load current), you can reduce costs by including modern CMOS drivers in the system. The newer CMOS drivers provide additional advantages (ESD protection, fail-safe capability, and decreased unit loading) that improve the system reliability and performance/cost ratios.

¹MAX485 transformer driver simplifies galvanic isolation.

²Skew is defined as the absolute value of the difference between the low-to-high and high-to-low propagation delays at the output of each channel.

Because RS-485 transceivers offer an easy way to implement the physical layer in industrial networks, several fieldbus standards specify an RS-485 serial port for communications. This article describes several fieldbus technologies, and highlights some particularly useful features of the available RS-485 transceivers.

Extensive data systems are employed in industrial plants to measure, collect, transmit, and display information. Valves must be controlled while temperature and pressure are measured, displayed, and fed to the process-control system. To connect the controller unit with sensors and actuators, many process and manufacturing facilities still include field multiplexers or multi-wire connections (based on 4mA–20mA loops or 0–10V circuits). Because the wiring required in those older systems is enormous, modern plants often save wiring effort by employing a serial, real-time, data-link industrial network (fieldbus system) for process and manufacturing control.

Fieldbus systems are similar to the widespread Ethernet office networks, in that a single bus connects all devices on one network to a central controller. Not only does that arrangement require substantially less wire, it also increases the system modularity. All devices are addressed via software, so any device can be connected to any socket along the network. The master detects which device is connected to the network, and initiates the action required to start communications.

A fieldbus provides other advantages over Ethernet, which may explain why Ethernet has not yet run the last mile in connecting PLCs and industrial PCs to field sensors and actuators. One fieldbus advantage is determinism, meaning that signals are received in real time, and the recipient immediately provides an acknowledging signal. Determinism is obviously required for an alarm signal that must be distributed in real time.

Fieldbus networks are also robust. Industrial networks must often guarantee gas-tight connectors and operate over the industrial temperature range of -45°C to +85°C (most Ethernet controller ICs are specified only for 0–70°C operation). It is possible to create an industrial Ethernet system that includes the additional protocol software for determinism, robust connectors, and industrial-temperature-range controller ICs, but such networks are more expensive. They also incur additional cost in compensating for high protocol overhead, which requires a higher data rate than that of a regular fieldbus.

RS-485/RS-422 Fieldbus

Many fieldbus standards specify RS-485 or RS-422 transceivers for implementing the physical layer in an industrial network. RS-485 transceivers are inexpensive, and they offer various useful features including multiple speed ranges. The following major fieldbus standards either transmit over RS-485 or include an RS-485 version among others:Attached Resource Computer Network (ARCNET): provides data rates up to 10Mbps. Started by SMC/Datapoint (USA) in 1977, it began as an office network and now serves industrial plants as well. Very flexible.

Bitbus: up to 375kbps; started by Intel (USA) in 1984. Used mainly for communication between programmable logic controllers (PLCs) and the main controller in manufacturing applications.

European Installation Bus (EIB): up to 9600bps; started in 1989 (Germany). Used in building automation.

Flux Information Processbus (WorldFip): up to 2.5Mbps (typically 1Mbps); started in 1984 (France). Mainly for industrial process automation in France and Italy.

Local Operating Network (LON): up to 1.25Mbps; started by Echelon Inc. (USA) in 1990. Used mainly for building automation.

Process Field Bus with decentralized peripherals (PROFIBUS DP): up to 12Mbps; started by PNO (Germany) in 1993. Used mainly in manufacturing automation.

INTERBUS: up to 2Mbps (typically 500kbps); started by Phoenix Contact (Germany) in 1987. Used mainly in manufacturing automation.

Other standards (such as CAN) have a different physical interface, but we will consider only the RS-485 PROFIBUS DP and Interbus. They have the largest market share and the highest growth rate in industrial RS-485 networks. For additional information about fieldbus standards, see http://www.fieldbusworld.com.

INTERBUS

Organized in a ring structure, the INTERBUS network has a low protocol overhead and a standard 500Mbps data rate that allows rapid data transfer. The maximum data rate was increased to 2Mbps in 2001, and that will be the standard data rate in future high-speed systems.The backbone of an INTERBUS is the remote bus, headed by a bus master that controls data communications. Each remote bus device (slave) is connected to the follow-on device via full-duplex, RS-422 point-to-point connections as shown in Figure 1. A maximum bus length of 400m is allowed between any two slaves, and the total bus length is limited to 13km. Each slave connects to the bus via two full-duplex RS-422 transceivers, one on each side of the slave. Those connections provide a repeater function that ensures good transmission quality over the entire network.

Figure 1. An INTERBUS network can include local- and remote-bus data loops, all operating in the 4-wire, full-duplex communication mode. Multiple local-bus loops are allowed.

No more than 512 slaves may be connected to one master, and each slave has its own power supply. A slave may also function as a bus-coupler (a bus-interface module) that feeds a local bus of up to eight devices. The local bus is limited to 10m (10 meters) in overall length and to 1.5m between any two devices. Local bus communication is implemented over pairs of 2-wire cables, using full-duplex CMOS-level signals rather than the standard RS-422-level signals.

The INTERBUS standard requires that components in a network be certified by an accredited test laboratory. Any PCB designer may apply for such a certificate at the local INTERBUS clubae representing an international association of companies whose common goal is to push (INTERBUS applications).

RS-422 Transceiver Features

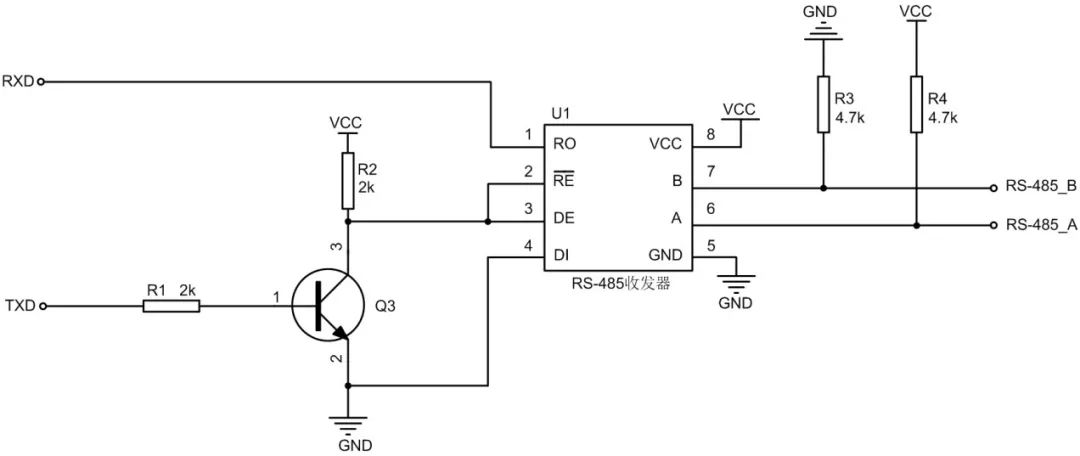

The full-duplex RS-485 transceiver in an INTERBUS remote bus (usually called an RS-422 transceiver) must support a data rate of at least 500kbps (Figure 2). Future generations will require more than 2Mbps. Current applications usually include 75179-compatible drivers in spite of their high quiescent supply current. Even the (so-called) low-power 75LBC179 has a typical quiescent current of 4.2mA per device. The 10Mbps MAX3087E is a low-power alternative that draws a no-load supply current of only 475µA, with correspondingly lower full-load supply current.

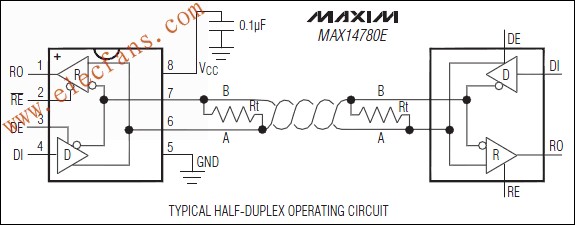

Figure 2. Typical RS-422 transceiver in an INTERBUS remote bus.

Supply current is important in minimizing power dissipation. The housing of a fieldbus device may be quite small, and therefore difficult to provide with an effective heatsink. Moreover, many applications require a galvanically isolated bus, so power must be distributed to the RS-485 transceiver across an isolation barrier.

The MAX3087E also provides ±15kV of ESD protection. A technician can destroy valuable unprotected electronic devices just by touching them, and that static discharge can occur with a single contact during installation of the fieldbus cable. The ESD structures included in Maxim ICs protect both the transmitter outputs and receiver inputs of multiple interface circuits against electrostatic discharge. During manufacture, the ICs' positive and negative rails are tested in 200V increments according to the Human Body Model (IEC Standard 1000-4-2). Thus, unlike competitive parts that may withstand 15kV strikes but fail at 6kV, the Maxim parts guarantee protection against the smaller ESD strikes as well.

PROFIBUS DP

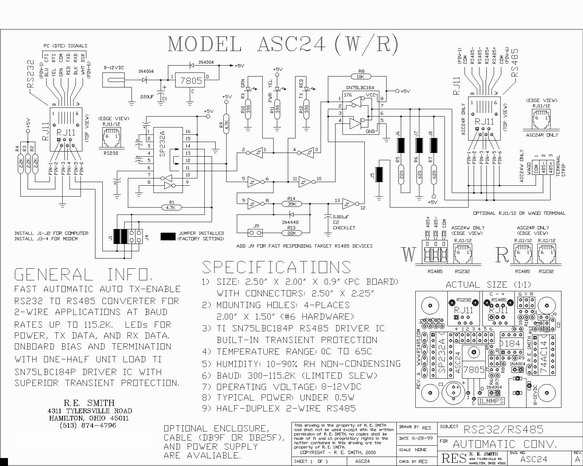

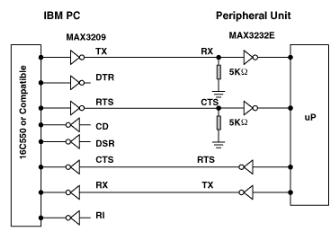

The PROFIBUS DP is organized in a line configuration, which lets you add and remove peripherals while the bus is operating (Figure 3). Most applications operate with the maximum data rate of 12Mbps, but 1.5Mbps is common and rates down to 9600bps are defined. The maximum bus length for copper cables at 12Mbps is 100m, but at lower data rates the use of repeaters can extend the total bus length to 9.6km.

Figure 3. The PROFIBUS network is laid out in a single line. Up to five bus segments are allowed, each containing up to 32 nodes. A Mono Master System is shown with a single master per segment.

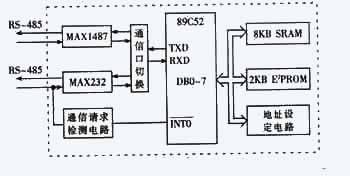

PROFIBUS DP connects to the bus using half-duplex RS-485 transceivers, which transfer data over a single, shielded, twisted-pair cable. PROFIBUS also allows the possibility of an optical connection using plastic fiber. Other family members are PROFIBUS FMS, an older version for the process-management level that has been mostly replaced by Ethernet, and PROFIBUS PA, an intrinsically safe version for process-control applications.

PROFIBUS DP allows up to 32 nodes per bus segment, including masters, slaves, and any repeaters. You can add bus segments up to a total of five, with each segment isolated by a repeater. The bus size may be extended in this way to an overall total of 126 nodes. PROFIBUS DP has a high overhead for protocol, because various diagnostic functions are added to the actual message to guarantee safe data transmission.

Communications are controlled by one or more Class-1 masters. The system also includes Class-2 masters, which compose the human-machine interface used to program devices and operate systems on the bus. A slave can be a sensor, an actuator such as a magnetic valve, or a decentralized digital or analog input or output. The PROFIBUS standard requires that all end equipment connected to a PROFIBUS be certified by an accredited test lab (see http://www.profibus.com).

RS-485/RS-422 Transceiver Features

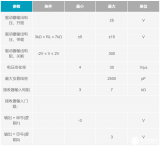

The half-duplex RS-485 transceivers in a PROFIBUS DP network must be capable of handling data rates ≥ 12Mbps. To guarantee a valid receiver-input voltage under worst-case load conditions, the differential driver outputs must be able to deliver ≥ 2.1V at full load (27Ω). And to minimize signal distortion, the driver and receiver outputs should exhibit ≤ 2ns of data skew². Most PROFIBUS applications require specially sorted 75ALS176 trans-ceivers to achieve that level of performance. A new family of 20Mbps, half-duplex RS-485 transceivers (MAX3463/MAX3464) offer several advantages while meeting the PROFIBUS DP requirements:- Data rates to 20Mbps.

- Substantially lower supply current (≤ 4mA, compared with ≤ 30mA for the 75ALS176). Low supply current for the transceiver saves cost and board space, because a PROFIBUS DP interface is galvanically isolated in most cases.

- ESD protection on all input and output pins protects the ICs against ESD strikes to 2kV.

- True fail-safe capability.

Figure 4. Typical RS-485 transceiver for PROFIBUS DP.

Maxim's true failsafe feature, implemented in MAX3463/MAX3464 devices, avoids external biasing resistors by substituting a precise receiver-threshold range (-50mV to -200mV) that complies fully with RS-485 specifications while guaranteeing that a 0V input produces a logic "High" at the receiver. The remaining termination resistor (approximately 200Ω) is connected between the differential lines. By eliminating the 330Ω pullup and pulldown resistors otherwise needed, that connection saves additional power.

The capability of a standard RS-485 driver to drive up to 32 unit loads sets the 32-node maximum for a PROFIBUS DP bus segment. One unit load is defined as 12kΩ, which corresponds to the input impedance for a standard RS-485 receiver. The higher input impedance of MAX3463/MAX3464 receivers (48kΩ, which is 1/4 unit load) allows 128 transceivers on the bus. Any combination of RS-485 transceivers can connect to one bus segment, provided the net parallel impedance of those circuits remains above 375Ω (32 unit loads).

Conceivably, the PROFIBUS DP size could be increased to 128 nodes per segment, for a total of 640 nodes in five segments. The MAX3463 includes another useful feature. When bus nodes are powered up or plugged into a "hot" backplane, there follows a short interval in which the processor or control ASIC executes its power-up sequence. The processor's output drivers are in a high-impedance state during that time, and are therefore unable to drive the RS-485 transceiver's control lines (active-low RE, DE, DI) to defined logic levels.

Leakage current from those high impedance drivers (as much as 10µA) can cause the RS-485 circuits control lines to drift high or low. In addition, parasitic capacitance on the circuit board can couple the control lines to either GND or VCC. These factors cause the control lines to drift toward levels that may enable the circuit's transmitters (A and B). To avoid that condition, the MAX3463 includes hot-swappable inputs that disable the MAX3463 control lines as VCC ramps up from 0V. Hot-swap inputs overcome the leakage currents and parasitic capacitances that might otherwise pull the control lines to the enabled state. Full-duplex versions (MAX3460-MAX3462) are available for high-speed RS-422 applications.

Because fieldbus systems can include a large number of RS-485 or RS-422 drivers, power delivered to the drivers can represent a significant part of the system cost. That is particularly true when supplying the power across an isolation barrier. Because legacy RS-485/RS-422 drivers require considerable supply current (as much as 30mA quiescent, plus load current), you can reduce costs by including modern CMOS drivers in the system. The newer CMOS drivers provide additional advantages (ESD protection, fail-safe capability, and decreased unit loading) that improve the system reliability and performance/cost ratios.

¹MAX485 transformer driver simplifies galvanic isolation.

²Skew is defined as the absolute value of the difference between the low-to-high and high-to-low propagation delays at the output of each channel.

电子发烧友App

电子发烧友App

评论