Optical Design Tools for Backlight Displays

Backlights are used for compact,portable, electronic devices with flat panel Liquid Crystal Displays (LCDs) that require illumination from behind. Applications include devices as small as hand-held palm pilots and as large as big-screen TVs. Goals for backlight design include low power consumption,large area with small thickness, high brightness, uniform luminance, and controlled viewing angle, either wide or narrow. To achieve these challenging design goals with a cost effective and timely solution, it is necessary to use computer-aided optical design tools to expedite the design. This paper describes fea-tures in ORA’s LightTools? illumi-nation design and analysis software that enable the development of state-of-the-art backlight designs.

Optical Design and Analysis Tools for Backlights

Illumination or lighting systems take light from one or more sources and transform it in some way to produce a desired light distribution over an area or solid angle. Illumination design software must be able to model the geometric and optical properties of different types of light sources and transforming elements, and it must also be able to evaluate the paths of light using optical ray tracing through the model to calcu- late the final light distribution.

The light distributions are calculated using Monte Carlo simulations to calculate illuminance, luminance, or luminous intensity over the desired areas and/or angles. Rays are started from random locations and direc- tions from the source(s), traced through the optical system, and col- lected on receivers. Illuminance can be calculated for rays collected on surface receivers and intensity for rays collected on far field receivers. By defining a luminance meter for surface receivers, the spatial or angular variation of luminance can be calculated from that surface.

In some cases, it may be important to analyze the chromaticity of a dis- play. The spectral energy distribu- tion of the sources (such as LEDs) can be specified. The output of CIE coordinates, together with corre- lated color temperature (CCT), quantifies the colorimetric behavior of the display. An RGB photorealis- tic rendering of the display output can also be generated. All of these analyses are available in LightTools.

Aspects of backlight displays make particular demands on illumination analysis software. As will be dis- cussed, the means by which light is extracted from a backlight relies on either dense patterns of paint dots or patterned microstructures. Model- ing microstructure arrays in particu- lar can result in extremely large model sizes if created explicitly as a CAD model. LightTools provides the capability to define arrays of 3D textures that ray trace and render accurately but are not explicitly constructed as part of the geometric model, thereby resulting in much smaller model sizes and much faster ray tracing.

A second aspect of backlight analy- sis involves ray splitting and scatter- ing from the surfaces of the light guide. Because Monte Carlo simu- lations are used to analyze the illu- mination performance, a potentially large number of rays must be traced to get sufficient accuracy for com- parison of designs. It is most effec- tive to trace rays that carry most of the flux. This can be achieved by using probabilistic ray splitting to trace the paths with the most flux, and allowing use of aim areas or solid angles for scattering surfaces to direct scattered light in “important” directions (i.e., toward the display observer).

What is a Backlight?

A typical backlight consists of a light source, such as a Cold Cathode Fluorescent (CCFL) or Light Emit- ting Diodes (LEDs), and a rectangu- lar light guide, which is also referred to as a light pipe. Other elements than can be used include a diffuser, which enhances display uniformity, and a brightness enhancement film (BEF), which enhances display brightness.

The light source is usually located at one edge of the light guide to mini- mize the thickness of the display. Edge lighting typically uses total internal reflection (TIR) to propa- gate light along the length of the display. Figure 1 shows a schematic of a typical backlight design.

The backlight designer has several options for modeling light sources in LightTools. CCFL sources of differ- ent shapes (e.g., straight, L-shaped, U-shaped, or W-shaped, shown in Figure 2) can be rapidly defined using the Fluorescent Lamp Creation Utility. Reflectors for the lamp can be defined using a variety of Light- Tools geometric primitives, such as cylinders, elliptical troughs, and extruded polygons; reflectors defined in CAD systems may also be imported via standard data exchange formats (IGES, STEP, SAT and CATIA).

If LEDs are used, the designer can choose the desired LED model from pre-stored catalogs of models from Agilent, LumiLeds, Nichia, or Osram. Once the light is directed into the side of the light guide, the problem becomes extracting the light out of the light guide perpendicular to the direction of propagation.

As shown in Figure 3, the available power is highest at the source end of the light guide and falls off with increasing distance from the source. To obtain uniform output, the extrac- tion efficiency must increase with distance from the light source. Developing a light guide that exhib- its the necessary variation in extrac- tion efficiency is one of the primary tasks in designing a backlight. Two extraction techniques can be used. The printed light extraction technique uses patterns of paint dots on the bottom of the light guide to scatter light upward and out of the top of the light guide. The second technique, molded light extraction, relies on TIR from microstructures or textures patterned on the bottom surface to redirect light out of the top of the light guide.

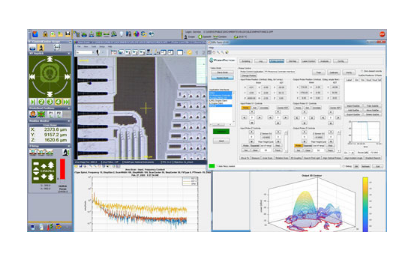

LightTools supports the design of light guides via the Backlight Design Utility. This tool (Fig- ure 4) assists the user in creat- ing the different parts of a backlight. There are options for adding source/reflector components to the model, BEF modeling, and setting up a receiver for illumination analy- sis. The main focus of the Backlight Utility is multiple tabs for setting up and modifying extraction mechanisms of different types.

For backlights using the printed light extraction method, the Backlight Utility provides options for linear variation in paint dot size and aspect ratio, as well as linear variation of dot spacing along the length of the light guide. This type of pattern variation will often give a good starting point for a uniform display, but is not sufficient to meet the final uniformity requirements. Additional control of output uniformity can be obtained by allowing non-linear variation of extraction parameters.

An approach that gives very flexible control with a minimum of parame- ters is to define the variation of a parameter in terms of a quadratic Bezier curve. The LightTools 2D Zone Utility is used to set up nonlin- ear patterns.

Figure 5 shows an example using painted light extraction in which three parameters (paint dot width, height, and vertical spacing) are var- ied to create variable extraction behavior.

The output uniformity is shown in Figure 6. The slice on the right shows that the average output lumi- nance is constant.

The second extraction method, molded light extraction, uses the 3D texture capability in LightTools. The 3D texture feature is designed to ray trace repetitive structures very effi- ciently and store the information very compactly. Models created using explicit geometry can trace more than 30 times slower and have model files more than 100 times larger than equivalent models cre- ated using 3D textures. Three differ- ent basic shapes are available: spheres, prisms, and pyramids (Figure 7).

The Backlight Utility provides a means for setting up linearly varying patterns of the microstructure types.

The 3D Texture Utility can be used to vary the texture parameters non- linearly using a quadratic Bezier curve. An example where a groove microstructure (modeled using the prism 3D texture) is used as an extraction mechanism is shown in Figure 8.

The resulting light guide and its per- formance is shown in Figure 9.

Optical Calculations for Backlights

Two of the most important optical quantities for backlight displays are display luminance and illuminance uniformity on the top of the light guide. Calculation of luminous intensity and various colorimetric quantities (CIE coordinates and CCTs) are important as well. LightTools has built-in support for these calculations and a number of features to aid in understanding the results of the Monte Carlo simula- tions used to generate the data.

Monte Carlo simulations are the foundations of the illumination cal- culations in LightTools. It is gener- ally understood that random number generators are used to pick starting ray positions, directions, and wave- lengths to sample the light distribu- tions on the receivers. The convergence of the simulations can be dramatically affected by how the “random” numbers are chosen. Using low discrepancy (Sobol) num- ber sequences, which are not random at all, can improve the reduction of error from to 1/N, where N is the number of rays at the receiver. A comparison of colorimetric results using random number sequences (Figure 10) and Sobol number sequences (Figure 11) is shown on page 6. For this case, it would take 128,000 rays using a random num- ber generator to equal the accuracy of a 16,000-ray Sobol sequence sim- ulation. It is important to recognize the simulation convergence speed when comparing different software, since it is the speed with which you get to a certain accuracy level, not the speed it takes to trace a certain number of rays, that is important.

Receivers in LightTools collect ray data for illumination calculations.

The ray data is collected on data meshes for analysis and display. The user can interactively control the dimensions or number of bins in the data meshes. For a given num- ber of rays on the receiver, meshes with a small number of bins will have low spatial or angular resolu- tion but high relative accuracy (low error), while meshes with a large number of bins will have better reso- lution but lower accuracy (greater error). An error estimate can be dis- played for each bin in a mesh to help the user decide if enough rays have been traced in the simulation to meet the resolution and accuracy neces-sary to assess the design (Cassarly, W.J., Fest, E.C., and Jenkins, D.G., 2002). If more rays are needed, the user may interac- tively continue the simulation until the goals are met.

An important aspect of backlight analysis involves ray splitting and scattering from the surfaces of the light guide. The nature of the light guide is that a ray can bounce around the inside of the light guide numer- ous times prior to becoming absorbed or exiting the guide. If a ray is split into a transmitted and reflected part for each surface inter- action, an extremely large number of split rays result, most of which carry little energy, thereby slowing the analysis. An example of this is shown in Figure 12, which shows the many paths of a single starting ray due to beam splitting.

A simulation was run where 2000 rays were started from the source and, due to ray splitting, 277,948 rays were collected on the receiver (Figure 13). Because most of the rays reaching the receiver had little energy, the error for the result was 42%.

If, instead, one traces the ray proba- bilistically, with the probability of a ray transmitting or reflecting deter- mined by the Fresnel loss coeffi- cients or scattering properties at the surface, the bulk of the ray tracing time will be spent following the flow of the energy in the system, thereby speeding analysis. The results of a simulation where 200,000 rays were started from the source are shown in Figure 14. In this case 118,969 rays reached the receiver with an error estimate of 6% for the calculation. The probabilistic ray trace mode reduced the error in the calculation by 7x and, at the same time, reduced the calculation time by 42%.

Finally, diffusers are sometimes used above the top surface of the light guide to improve the angular unifor- mity of the display. Because diffus- ers spread rays over a wide angle, few rays would be scattered into the luminance meter aperture, and cal-culating the luminance normal to the display as measured by a typical luminance meter would require an extremely large number of rays. LightTools provides for aim areas or aim cones to be associated with scat-tering surfaces to allow the user to indicate where the scattered ray sam- ples should be directed. This is a form of importance sampling and is another method for improving the convergence of a Monte Carlo simulation.

Figure 15 shows a luminance meter and a backlight with a diffuser with- out an aim cone. Two thousand rays were traced from the source, and the luminance meter collected 40 rays, as shown by the raster plot of spatial luminance.

The value of importance sampling can be seen in Figure 16, which shows the same case but with an aim cone added to the diffuser. The aim cone is matched to the acceptance angle of the luminance meter aper- ture. When a ray is incident on the diffuser, LightTools will generate the scattered ray (with the flux into the aim area determined appropriately based on the full angular distribution of the diffuser model) into the aim cone, so that the luminance meter collects all of the scattered rays, thereby improving the convergence of the simulation. In this case, of the 2000 rays started, 1416 rays (71%) were collected by the luminance meter.

Additional Considerations

Backlights are widely used with Liq- uid Crystal Displays (LCDs), which are polarizing components. The capability to model polarizing com- ponents such as linear polarizers and quarter wave plates and evaluate their effects via polarization ray trac- ing can be critical to the success of an analysis. LightTools provides simple linear polarizer and retarder models, as well as specification of polarization components by their Jones or Mueller matrices. The polarization ray tracing feature, which the user can enable when needed, tracks the polarization state of the ray as it propagates using a Stokes vector

It is often necessary to treat compo- nents with optical coating with vari- ous transmission, reflectance, and polarization properties. Coatings are defined in LightTools in terms of their performance, which is often the only information available to the user. The average or the individual S or P values of reflectance and transmittance can be specified in terms of any two of the following parameters: angle of incidence, wavelength, X position, or Y posi- tion. A utility to convert coating stack definitions into the LightTools performance coating format is also available.

While most backlights use printed or molded extraction techniques, other approaches are possible. One is to use scattering from particles in the light guide itself. If the particle sizes and density are controlled appropri- ately, Mie scattering from the parti- cles can efficiently extract light from the light guide (Tagaya, et al., 2001:6274). LightTools can simu- late volume scattering according to the Mie theory for spherical particles or according to a user defined angu- lar distribution.

Exporting completed optical designs to CAD systems is often a necessary step toward manufacturing the light guide. Support of standard exchange formats such as STEP, SAT, or IGES is needed to accom- plish this. In the case of molded extraction designs, this also requires that the 3D texture definitions of the molded features be translated into explicit geometry for the data export, because data exchange stan- dards support the transfer of explicit geometry only. LightTools supports the standard formats and can option- ally export files with 3D textures converted to explicit geometry so that the entire backlight is repre- sented in the exchange file.

Summary

The field of backlight design contin- ues to evolve rapidly in response to market demand for better perfor-mance and reduced costs. This evolution is supported by the devel- opment of illumination design soft- ware with features specifically intended to reduce the design cycle time for new backlight development. Key features in LightTools address- ing model creation and size, ray trace and simulation time, and calcu- lation of a wide range of optical parameters relevant to the design of backlights have been identified and demonstrated.

Version 5.0 of LightTools, available in 2004, will add noise-tolerant illu- mination optimization to the features aimed at backlight designers. This will allow light extraction patterns, which maximize power and unifor- mity, to be determined automati- cally.

References

assarly, W. J., E. C. Fest, D. G. Jen- kins, “Error estimation and smooth- ing of 2D illumination and chromaticity distributions,” SPIE Proc., Vol. 4769, 2002.

Tagaya, A., M. Nagai, Y. Koike, K. Yokoyama, “Thin Liquid-Crystal Display Backlight System with Highly Scattering Optical Transmis- sion Polymers,” Applied Optics-OT, Vol. 40, Dec. 2001

电子发烧友App

电子发烧友App

评论