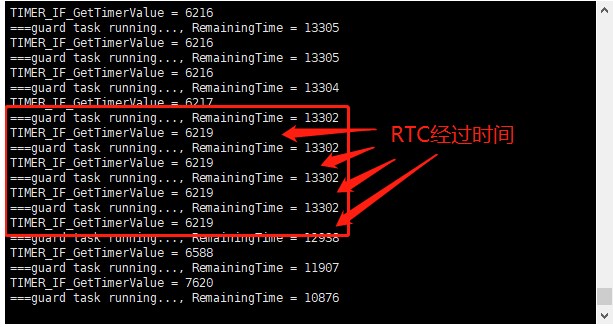

Abstract: Several Dallas Semiconductor real-time clocks (RTCs) integrate a voltage-regulated trickle charger, suitable for charging a manganese-dioxide lithium (ML) coin cell. The depth of discharge during use affects the service life of a ML cell. This application note discusses how to calculate the approximate cell life, based upon cell capacity, load, and depth of discharge.

ML secondary (rechargeable) cells are a relatively new technology, with some important advantages over primary (rechargeable) lithium coin cells (typically CR and BR). Some ML cells are capable of withstanding standard IR reflow profiles, while primary lithium batteries cannot. Using an ML cell can simplify the manufacturing process, eliminating the need to place the coin cell on a PCB post-reflow. A primary cell must either be sized to provide backup power over the expected life of the product, or provisions must be made for the cell to be replaced. While an ML cell has a lower energy density than a primary lithium cell, the ML cell can, in some applications, have smaller capacity, because it is recharged between uses. This allows for a smaller cell, decreasing the required PCB space. An advantage of the ML cell is its relatively low self-discharge rate (compared to capacitors, NiMH, and NiCad batteries) of approximately 1% per year, which allows extended life when the current load is small.

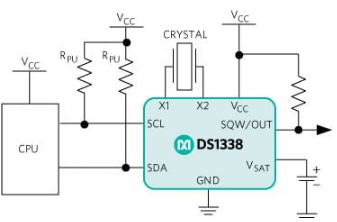

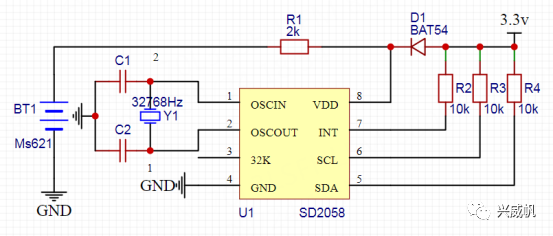

ML cells require a regulated-voltage charging source. Dallas Semiconductor has integrated the required charging source into a family of RTCs. The stand-alone DS12R885 has the charger on chip. In addition, there are module products that include the battery, charger, and RTC in a BGA package.

One issue with secondary cells is the number of charge/discharge cycles that they can withstand during a normal service life. For ML cells, the number of charging cycles is inversely related to the depth of discharge (DoD).

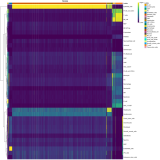

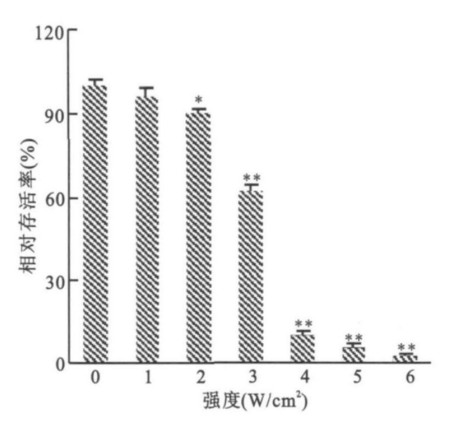

Figure 1 shows the effect that depth of discharge has on the number of charging cycles. The data are taken from the manufacturer of an ML614R battery. We can approximate the number of cycles for a given depth of discharge, and then calculate the approximate time to a particular discharge depth by multiplying the depth of discharge by the nominal cell capacity, and dividing by the load current. From there we can approximate the total life during backup (service life) by multiplying the calculated time by the number of expected cycles: total life = %DoD*(capacity/load)*cycles.

Figure 1. Depth of discharge vs. number of cycles for an ML614R.

We can plot the curves in Figure 2 using 2.2mAH as the battery capacity and using several load values.

An on-line calculator is available to calculate approximate service life based upon user-supplied battery capacity, load, and depth of discharge.

Figure 2. Service life vs. discharge depth for a 22mAH ML614R.

ML secondary (rechargeable) cells are a relatively new technology, with some important advantages over primary (rechargeable) lithium coin cells (typically CR and BR). Some ML cells are capable of withstanding standard IR reflow profiles, while primary lithium batteries cannot. Using an ML cell can simplify the manufacturing process, eliminating the need to place the coin cell on a PCB post-reflow. A primary cell must either be sized to provide backup power over the expected life of the product, or provisions must be made for the cell to be replaced. While an ML cell has a lower energy density than a primary lithium cell, the ML cell can, in some applications, have smaller capacity, because it is recharged between uses. This allows for a smaller cell, decreasing the required PCB space. An advantage of the ML cell is its relatively low self-discharge rate (compared to capacitors, NiMH, and NiCad batteries) of approximately 1% per year, which allows extended life when the current load is small.

ML cells require a regulated-voltage charging source. Dallas Semiconductor has integrated the required charging source into a family of RTCs. The stand-alone DS12R885 has the charger on chip. In addition, there are module products that include the battery, charger, and RTC in a BGA package.

One issue with secondary cells is the number of charge/discharge cycles that they can withstand during a normal service life. For ML cells, the number of charging cycles is inversely related to the depth of discharge (DoD).

Figure 1 shows the effect that depth of discharge has on the number of charging cycles. The data are taken from the manufacturer of an ML614R battery. We can approximate the number of cycles for a given depth of discharge, and then calculate the approximate time to a particular discharge depth by multiplying the depth of discharge by the nominal cell capacity, and dividing by the load current. From there we can approximate the total life during backup (service life) by multiplying the calculated time by the number of expected cycles: total life = %DoD*(capacity/load)*cycles.

Figure 1. Depth of discharge vs. number of cycles for an ML614R.

We can plot the curves in Figure 2 using 2.2mAH as the battery capacity and using several load values.

An on-line calculator is available to calculate approximate service life based upon user-supplied battery capacity, load, and depth of discharge.

Figure 2. Service life vs. discharge depth for a 22mAH ML614R.

电子发烧友App

电子发烧友App

评论